Control method for hone machining

A control method and honing processing technology, which is applied to the control of workpiece feed movement, honing machine tools, metal processing equipment, etc., can solve the problems of non-overlapping textures at the reversing position, achieve stable indicators, and improve geometric accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

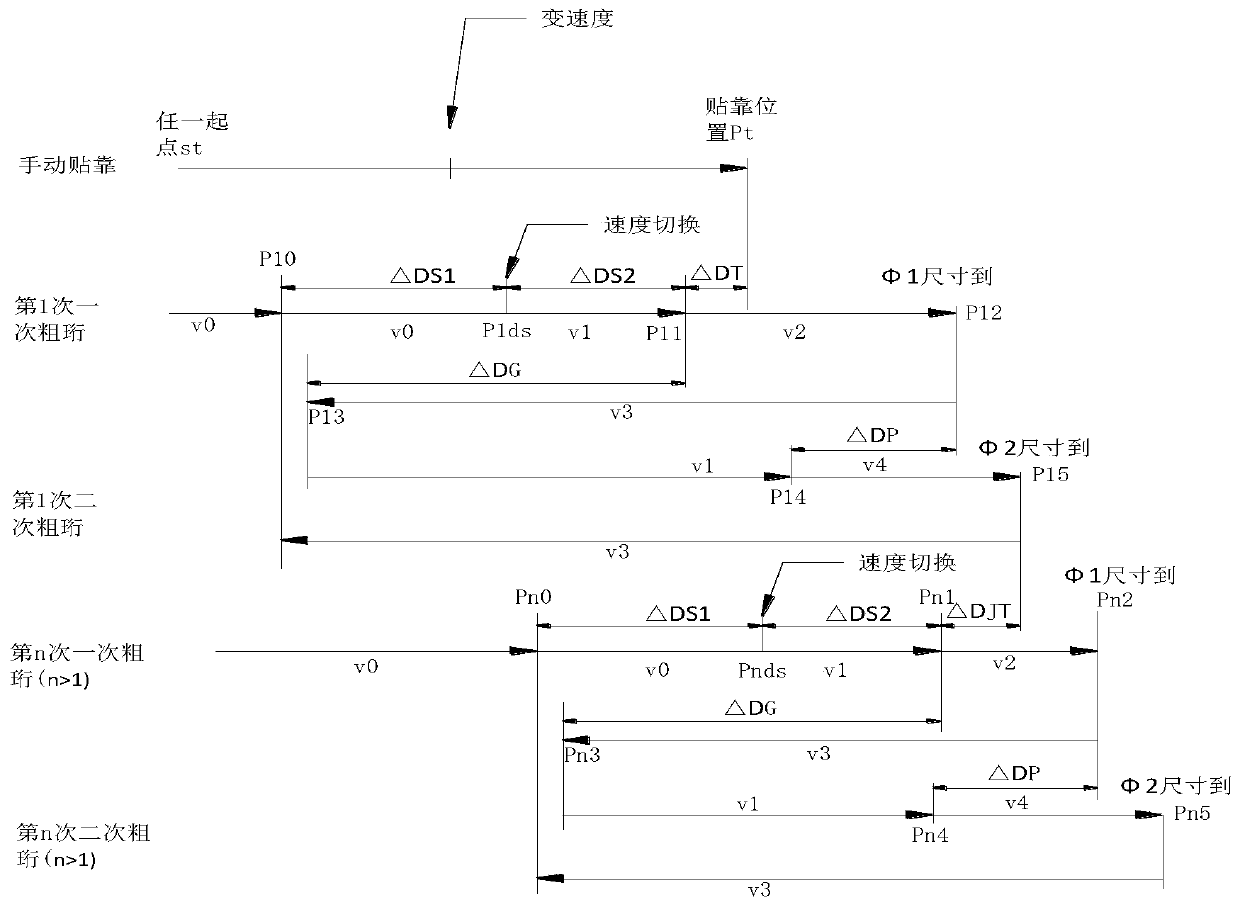

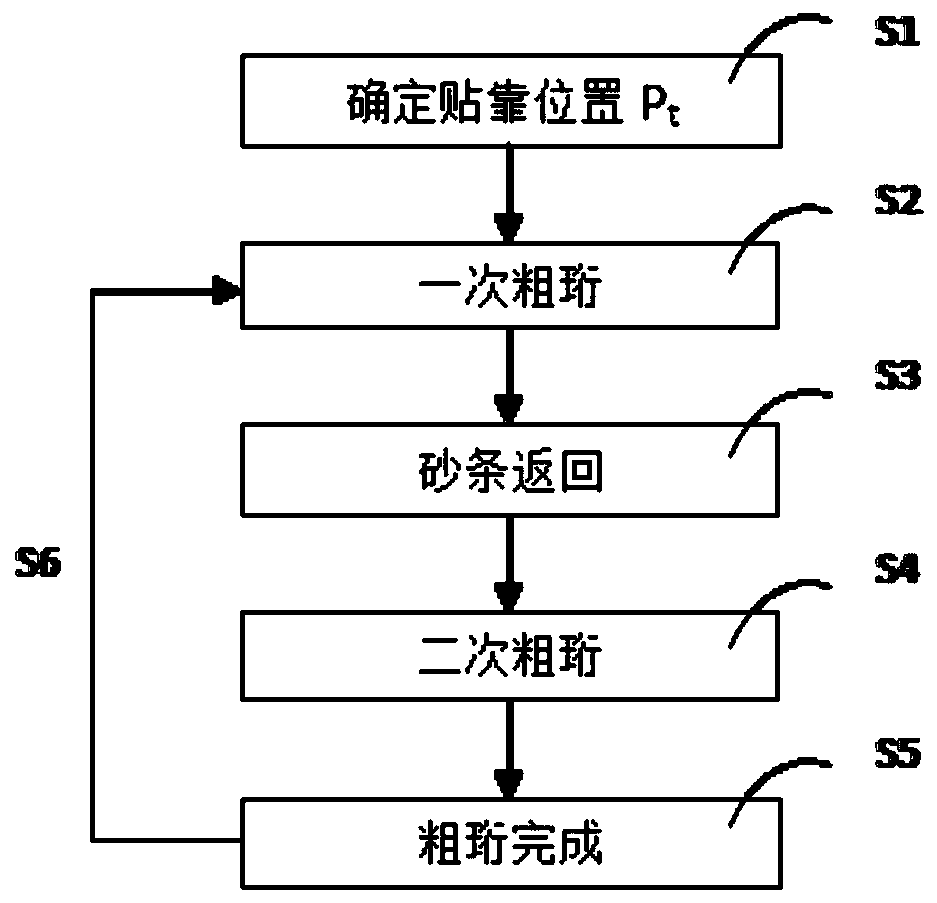

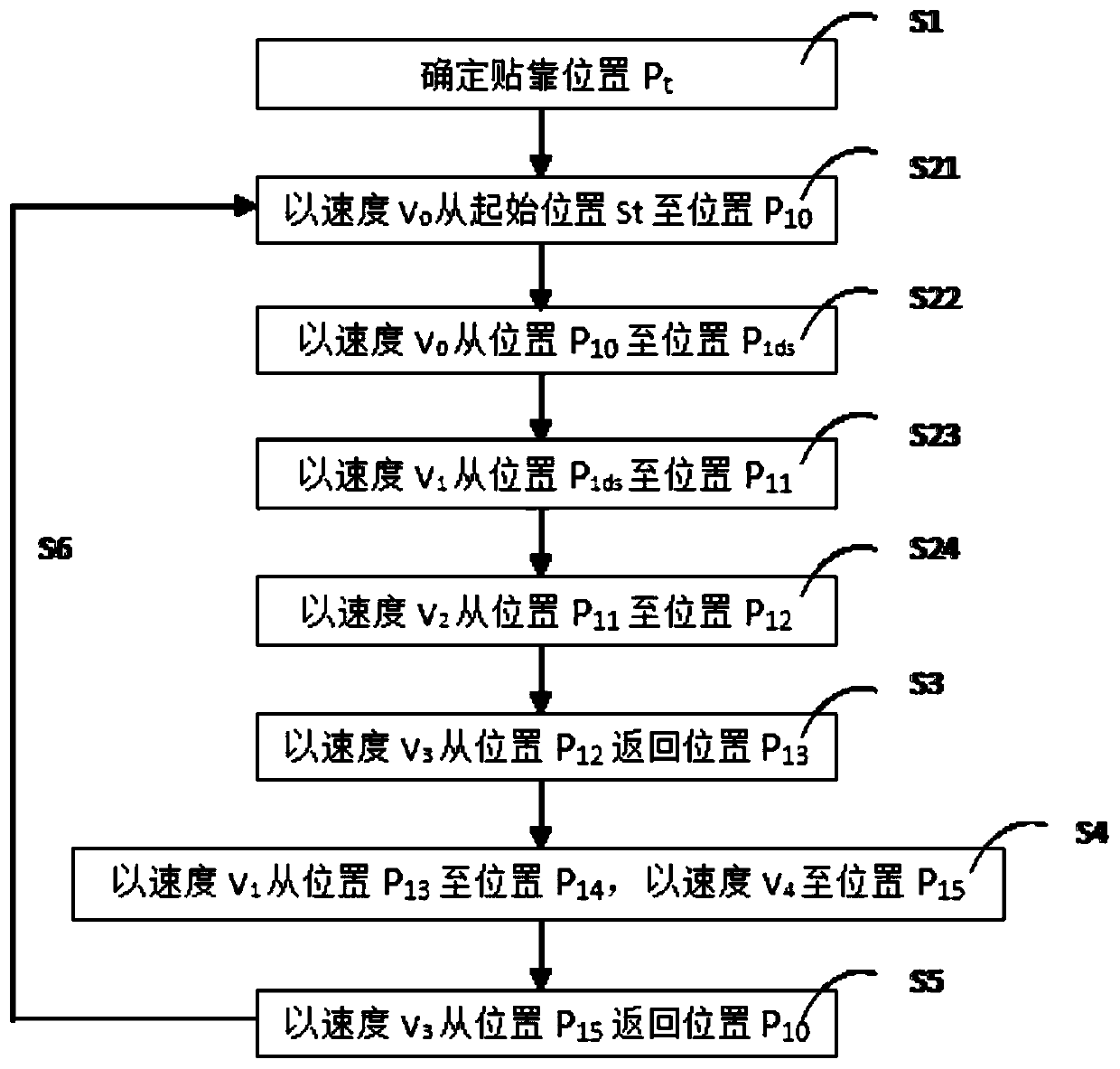

[0043] Such as figure 1 As shown, a control method for honing processing, which controls the feed of the sand bar at a speed, includes the following steps:

[0044] S1. Set the abutment force and abutment speed, and determine the abutment position P by setting the abutment force t ;The current abutment speed is inversely proportional to the current abutment force;

[0045] S2, a rough honing: the sand bar starts from the starting position S t at fast forward speed V 0 advance to the abutment position with the P t The distance is the position P of the protection gap △DS 10 , and then change the speed to advance to the abutment position P t The distance is the position P of the elastic deformation correction value △DT 11 , at the working speed V 2 Processing set size to position P 12 ; The step S2 further includes:

[0046] S21, the sand bar from the position P 10 continue at the fast-forward rate V 0 Advance protection gap △DS 1 to position P 1ds ;

[0047] S22. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com