Heat-storage-type two-position three-control separated temperature control method

A temperature control method and heat storage technology, applied in the direction of furnace control devices, waste heat treatment, lighting and heating equipment, etc., can solve the problems of heating quality influence, increase of production cost, increase of oxidation burning loss, etc., to improve the scope of application, Improve pass rate and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

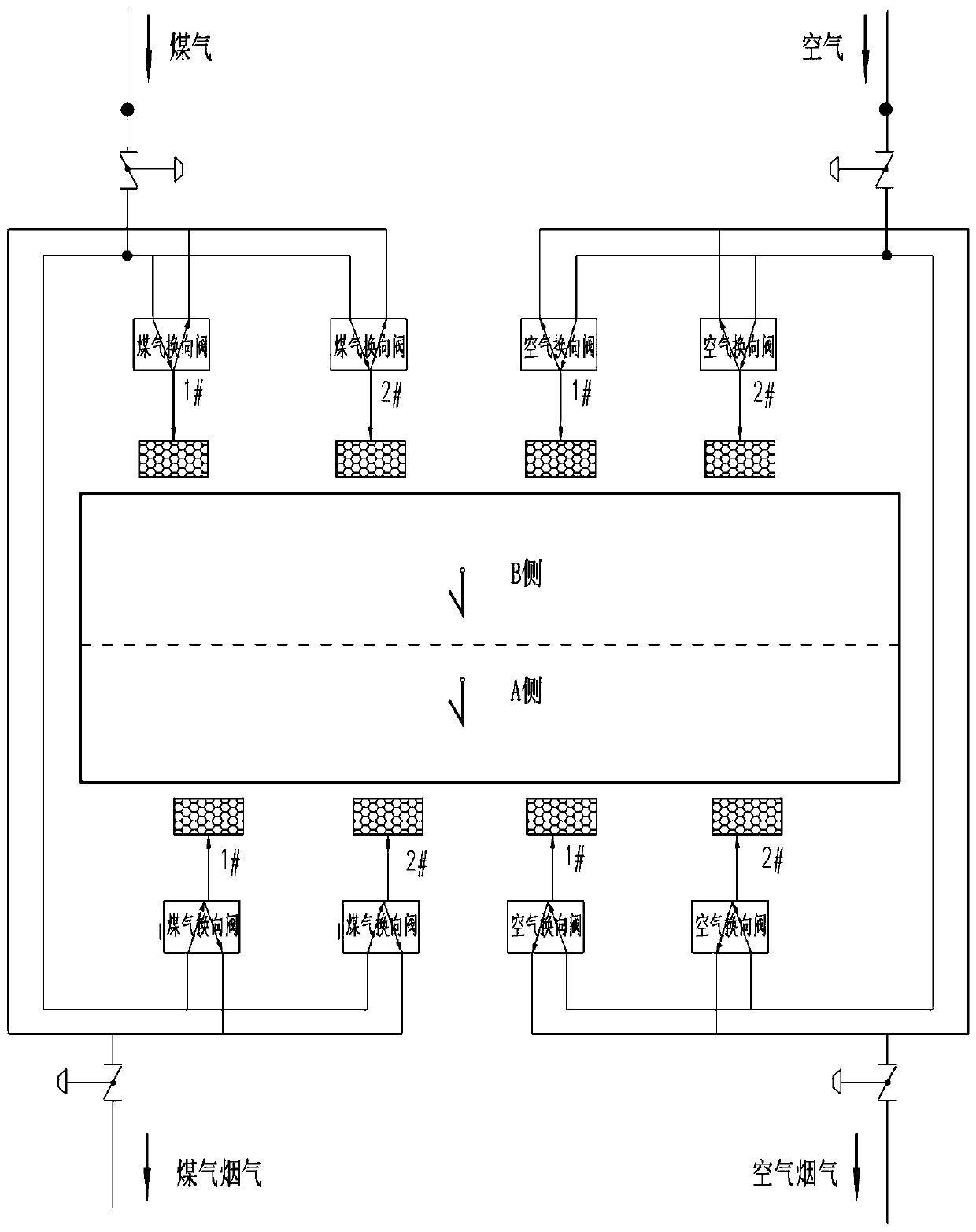

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] 1. Divide a control area into two virtual temperature control areas A and B

[0024] From the point of view of the dual regenerative combustion system, a control area has only one set of air flow control valve, gas flow control valve, air smoke flow control valve, and soot flow control valve. Theoretically, the temperature of this area depends on the air flow and gas flow The control valve is used to control the furnace pressure, and the furnace pressure is controlled by the air smoke and soot flow control valve. However, it is not feasible to use the traditional control method to control the temperature of the two virtual temperature zones A and B in a control zone. New regenerative two-position three-control split-side temperature control method.

[0025] 2. Group the regenerative combustion devices in the two virtual temperature control areas of A and B into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com