Composite material defect depth prediction method

A depth prediction and defect technology, applied in image data processing, instruments, calculations, etc., to achieve the effect of high prediction accuracy and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

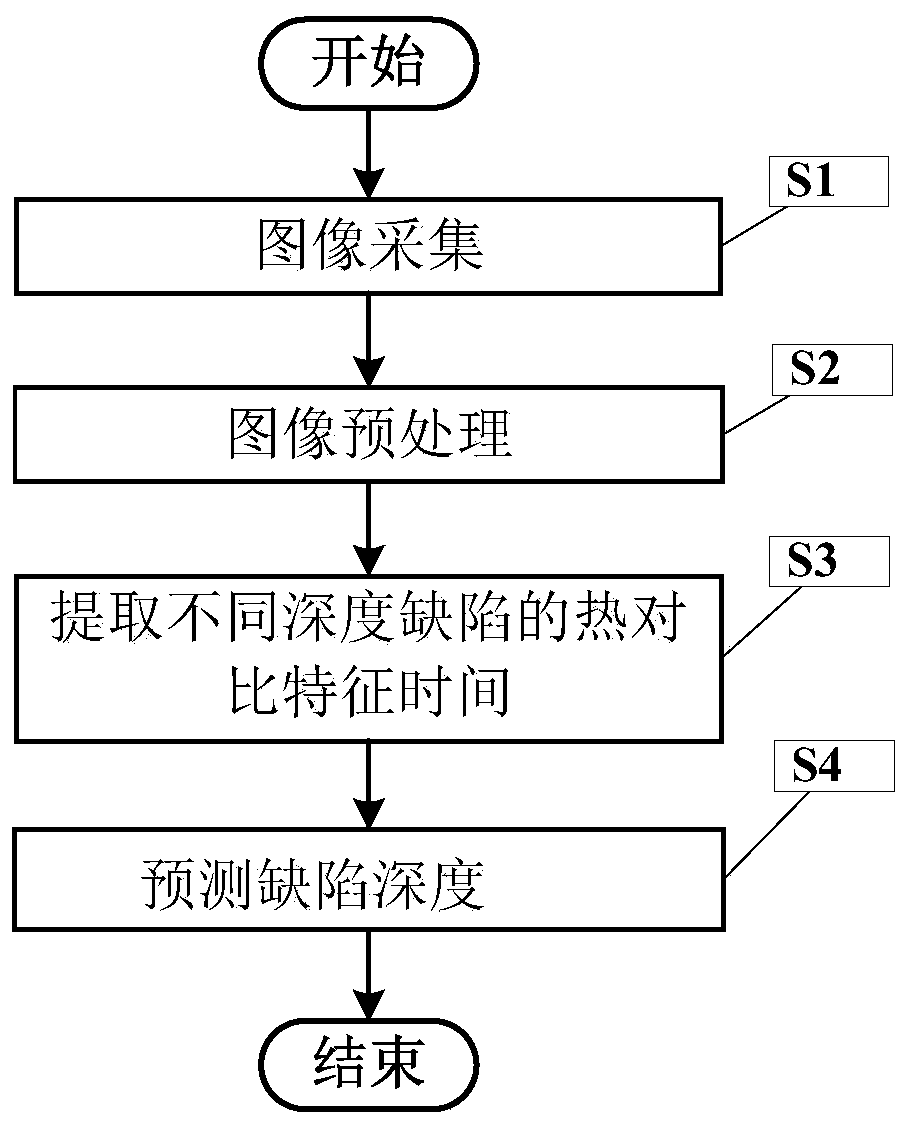

[0033] figure 1 It is a flow chart of a method for predicting the depth of composite material defects in the present invention.

[0034] In this example, if figure 1 Shown, the present invention a kind of depth prediction method of composite material defect, comprises the following steps:

[0035] S1. Image acquisition

[0036] Thermally load the test piece with a halogen lamp, and collect the infrared thermal image sequence of the test piece;

[0037] S2, image preprocessing

[0038] Use the matrix sparse decomposition algorithm to conduct qualitative defect analysis on infrared thermal image sequences, so as to determine all defect areas;

[0039] In this embodiment, for the obtained defect-containing infrared thermal image sequence, in order to reduce the number of thermal image frames and improve the accuracy of defect detection, preprocessing is performed by commonly used feature extraction algorithms, such as principal component analysis (PCA), independent Component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com