A built-in solenoid valve type semi-active damping continuously adjustable shock absorber and control method

A shock absorber, solenoid valve technology, applied in shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problems of small inherent damping, limited shock absorption effect, and reduced vehicle fuel economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

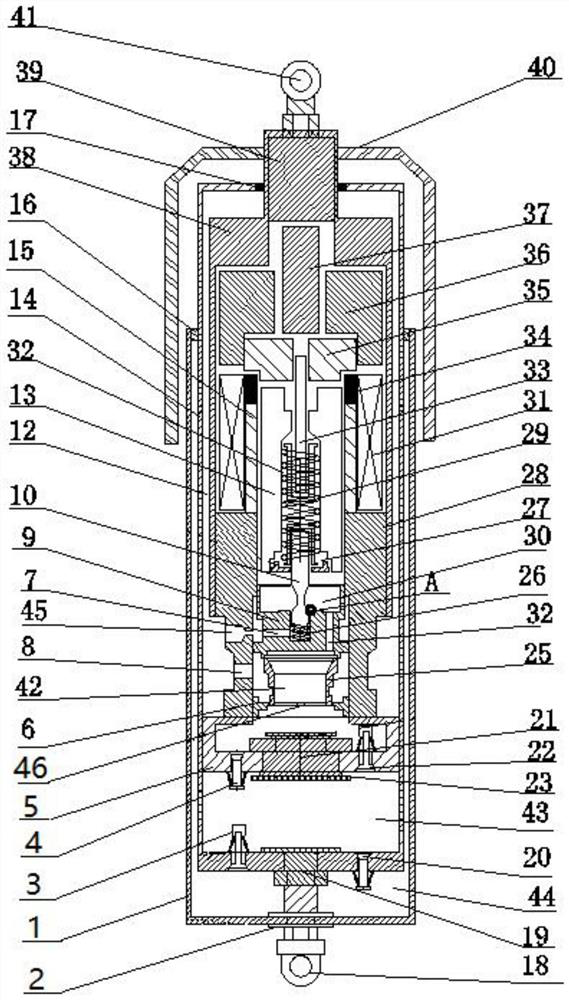

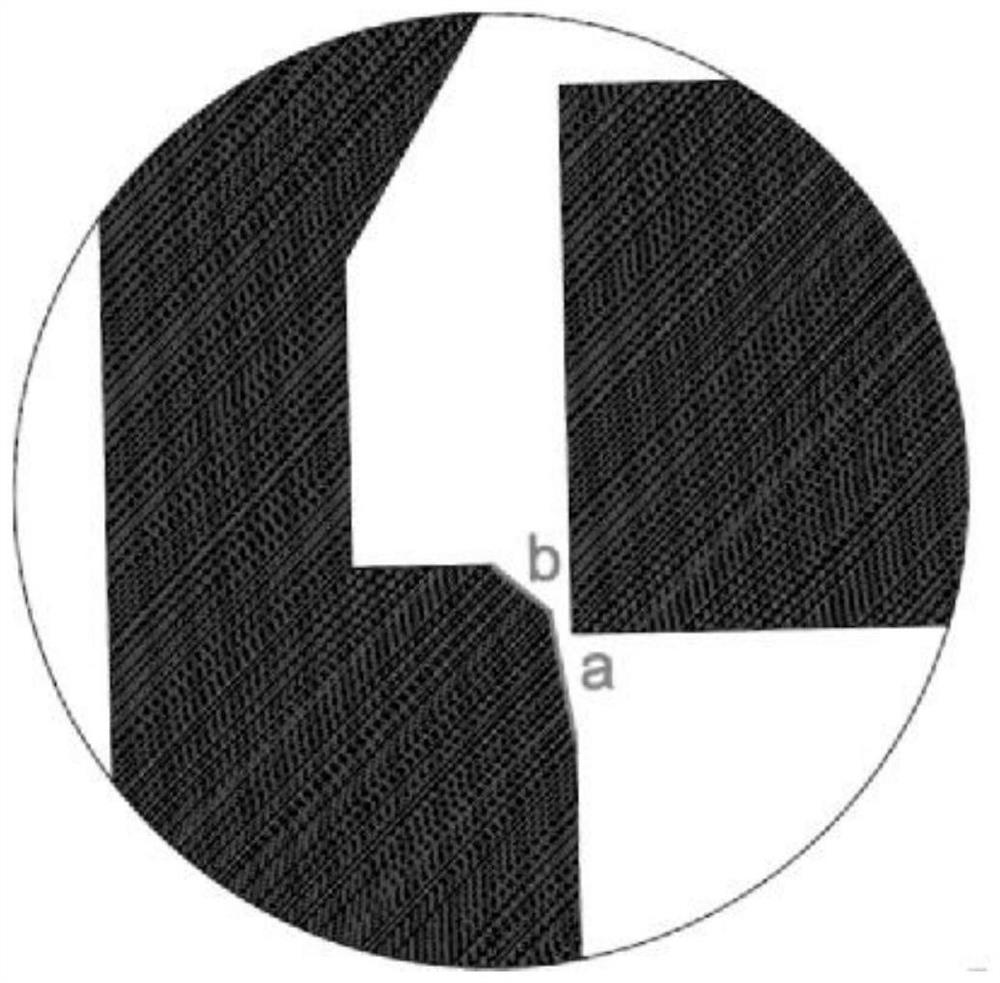

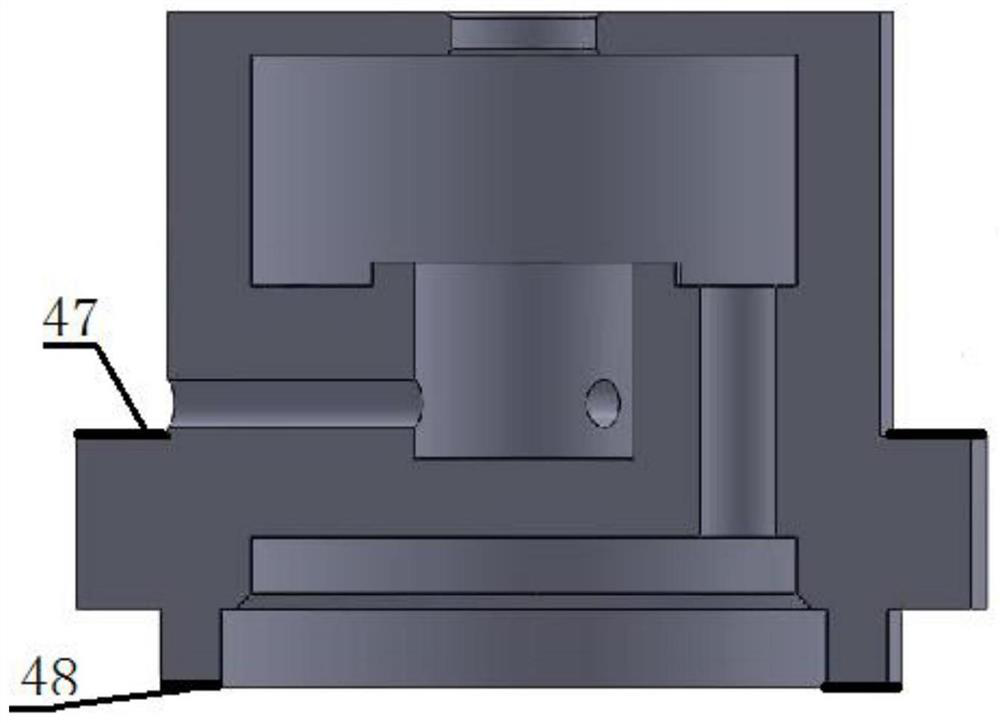

[0038] Such as figure 1 As shown, a built-in electromagnetic valve type semi-active damping continuously adjustable shock absorber, including a shock absorber body and a shock absorber control system, is characterized in that the shock absorber body includes a working cylinder (14), a storage Oil cylinder (1), shock absorber dust cover (40), bottom valve assembly, piston assembly, solenoid valve assembly, the oil storage cylinder (1) is half surrounded by the working cylinder (14), so The upper port of the oil storage cylinder (1) and the working cylinder (14) are sealed and connected with a fixed sealing ring (16), and the middle of the top cover of the working cylinder (14) is provided with a And the piston rod (38) of the shock absorber dust cover (40), adopt O-type sealing ring (17) to connect between the described working cylinder (14) and the piston rod (38), and the described piston rod (38) The outer side forms a closed structure with the working cylinder (14) and the...

Embodiment 2

[0045] Such as Figure 4 As shown, the shock absorber control system includes a shock absorber controller (39), a visual nervous system, a solenoid valve drive circuit, a solenoid valve, and a solenoid valve shock absorber. The hollow part at the top of the piston rod (38) is equipped with a shock absorber controller (39), and the input terminal of the shock absorber controller is connected with an unsprung mass velocity sensor for real-time detection of the unsprung mass velocity, Sprung mass velocity sensor for real-time detection of sprung mass velocity, vehicle body speed sensor, force sensor for real-time detection of output damping force of solenoid valve shock absorber, vertical displacement sensor for road surface input, vertical displacement of tire The sensor and the output end of the visual nervous system, wherein the input end of the visual nervous system is connected with a road scanner sensor. The speed sensor of the vehicle speed and the road surface scanner se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com