Smelting device for metal material processing

A metal material and discharge port technology, which is applied to the field of smelting devices for metal material processing, can solve the problems of inconvenient slag discharge and difficult movement of the smelting device, and achieve the effects of solving the inconvenient slag discharge, speeding up the melting speed and improving the smelting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

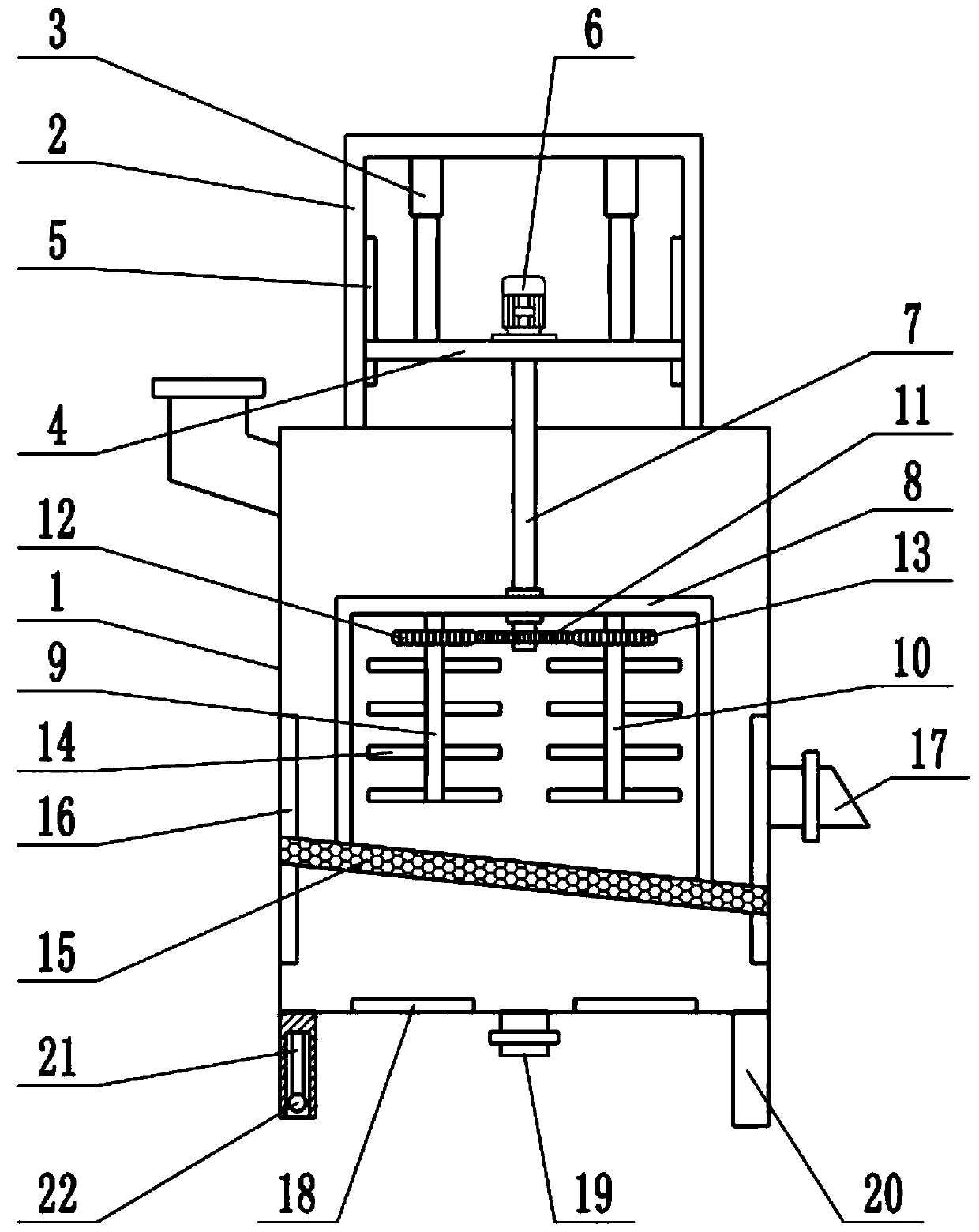

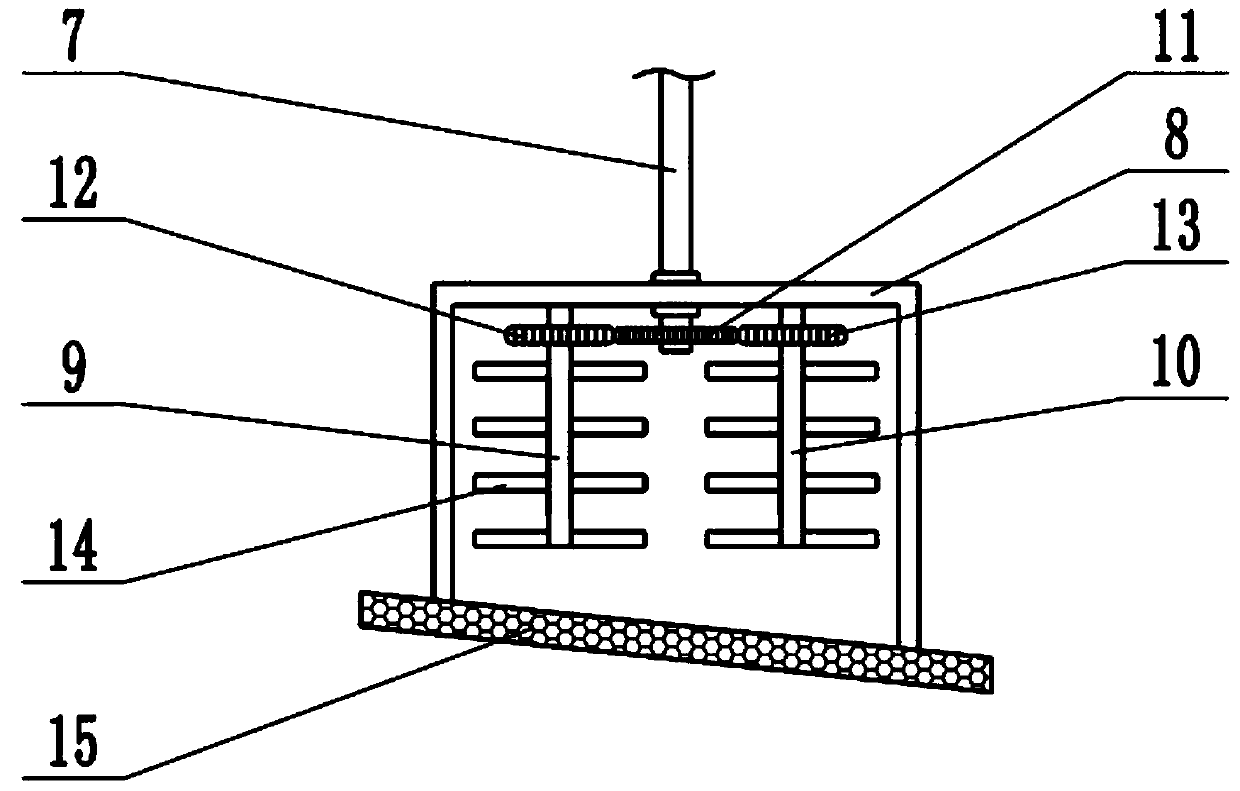

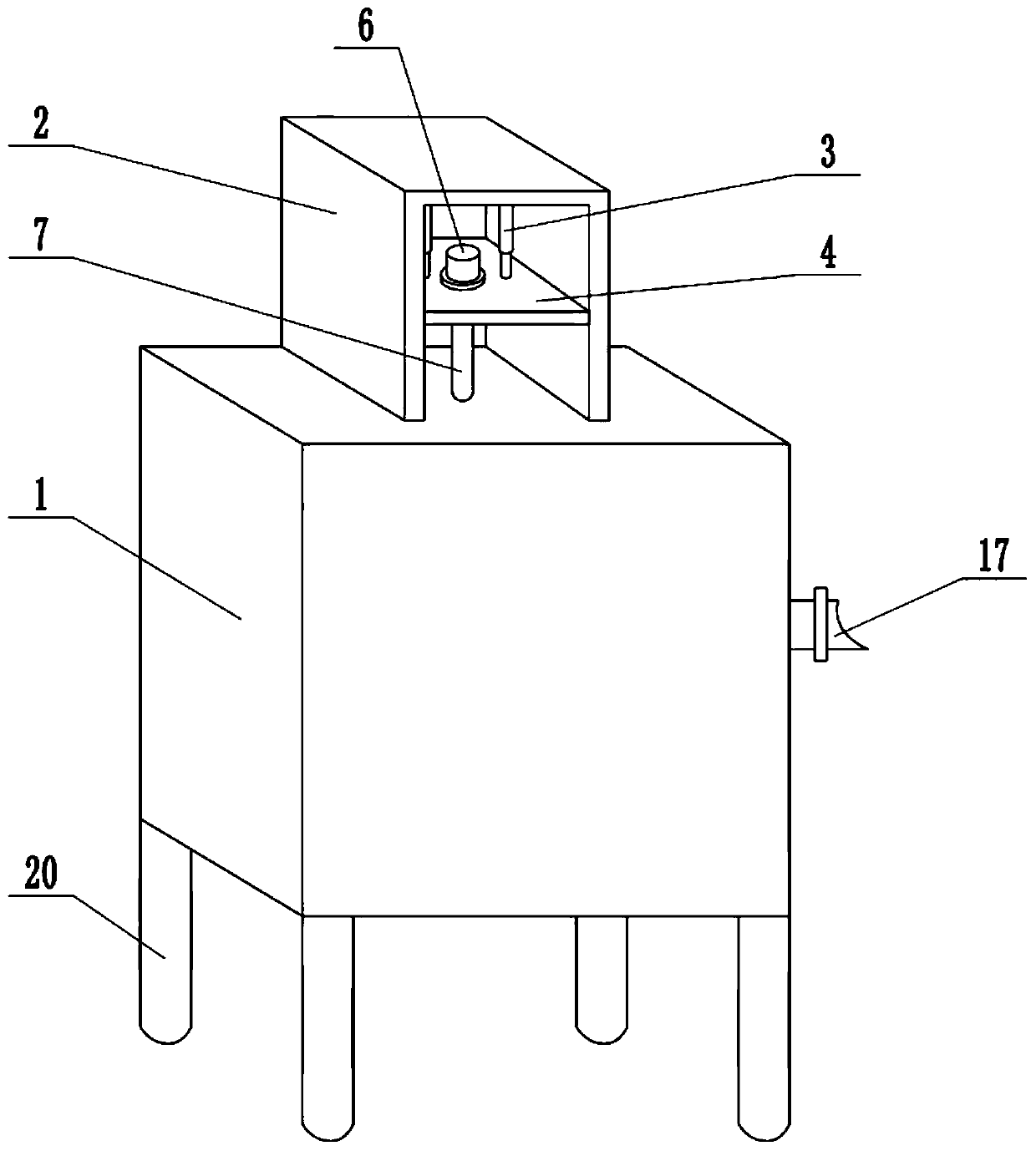

[0022] see Figure 1-3 , In the embodiment of the present invention, a smelting device for metal material processing includes a casing 1, a fixing frame 2, an electric heating plate 18 and a discharge port 19. A feeding port is installed above the side wall of the casing 1, and the feeding port is detachably installed. There is a cover plate, the raw material to be smelted is put into the casing 1 through the feeding port, the top of the casing 1 is fixedly connected with a fixing frame 2, a lifting plate 4 is installed inside the fixing frame 2, and a slide rail 5 is installed on the inner side wall of the fixing frame 2 , both ends of the lifting plate 4 are embedded in the sliding rail 5, the lifting plate 4 can slide up and down along the sliding rail 5, the upper surface of the lifting plate 4 is fixedly connected with a first telescopic mechanism 3, and the first telescopic mechanism 3 is an electric hydraulic telescopic cylinder , the top of the first telescopic mechani...

Embodiment 2

[0024] On the basis of Embodiment 1, the bottom of the housing 1 is fixedly connected with a supporting foot 20, the bottom of the supporting foot 20 is provided with a cavity, and a second telescopic mechanism 21 is installed inside the cavity, and the second telescopic mechanism 21 is an electro-hydraulic telescopic rod. A universal wheel 22 is installed on the lower end of the second telescopic mechanism 21. When the device needs to be moved, the second telescopic mechanism 21 is controlled to extend to drive the universal wheel 22 to move downward, so that the universal wheel 22 is connected to the ground. By jacking up the device, the device can be easily pushed to move.

[0025] Combined with Embodiment 1 and Embodiment 2, the working principle of the present invention is: during the smelting operation, the molten metal in the casing 1 is heated by the electric hot plate 18, and the metal to be smelted is put into the casing 1 through the feeding port, Start the motor 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com