A Method for Monitoring and Identifying Water Erosion Defects of Steam Turbine Blades

A technology for steam turbine blades and identification methods, applied to measuring devices, processing detection response signals, instruments, etc., to achieve the effects of improving safety and economy, increasing service life, and reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the purpose, technical effects and technical solutions of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention; obviously, the described embodiments It is a part of the embodiment of the present invention.

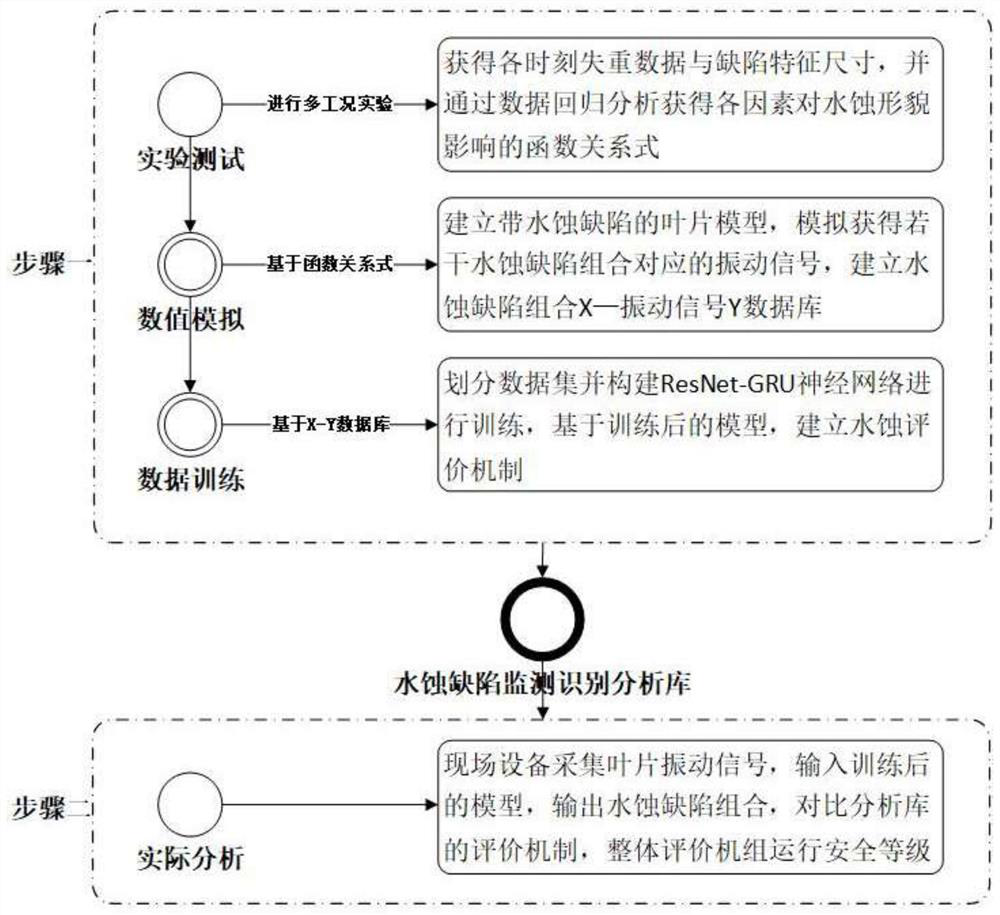

[0046] see Figure 1 to Figure 8 A method for monitoring and identifying water erosion defects of steam turbine blades provided by an embodiment of the present invention is mainly based on experimental measurement, numerical simulation and data training analysis, and the basic implementation process includes two steps of sampling, modeling, storage and actual operation analysis (see figure 1 ).

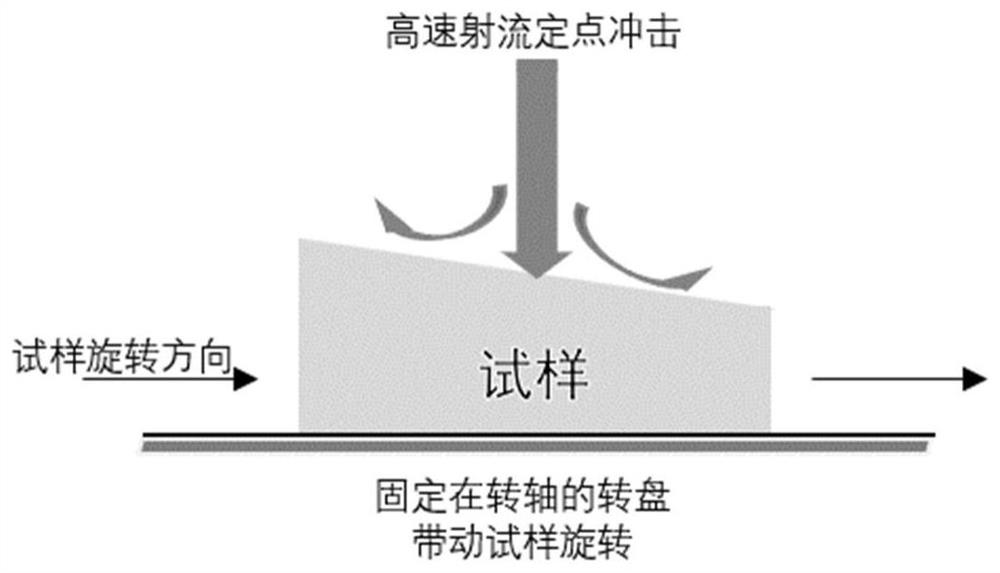

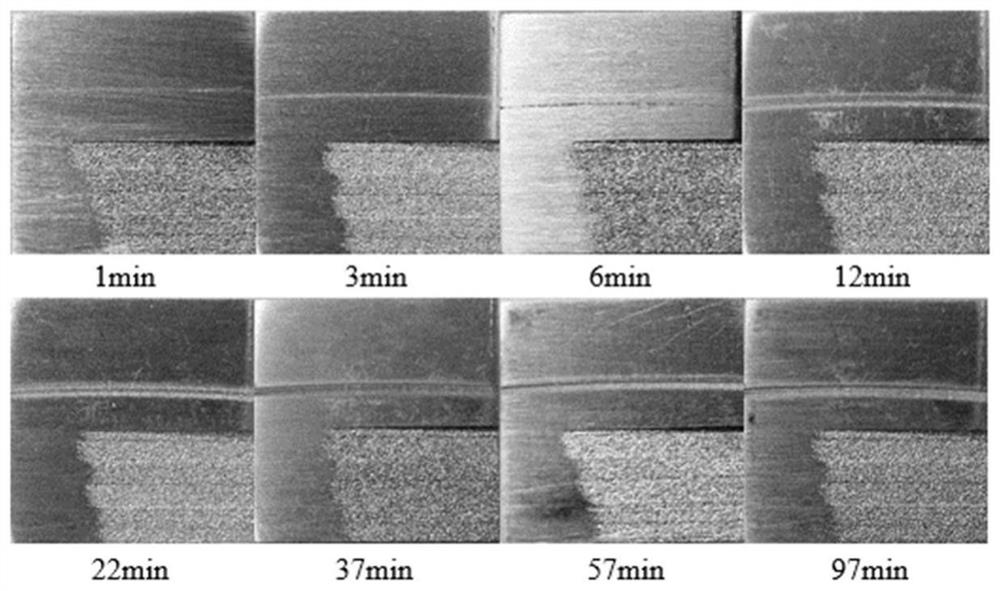

[0047] Step 1 is sampling, modeling, and storage, which can be divided into three stages: experimental measurement, numerical simulation, and data training. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com