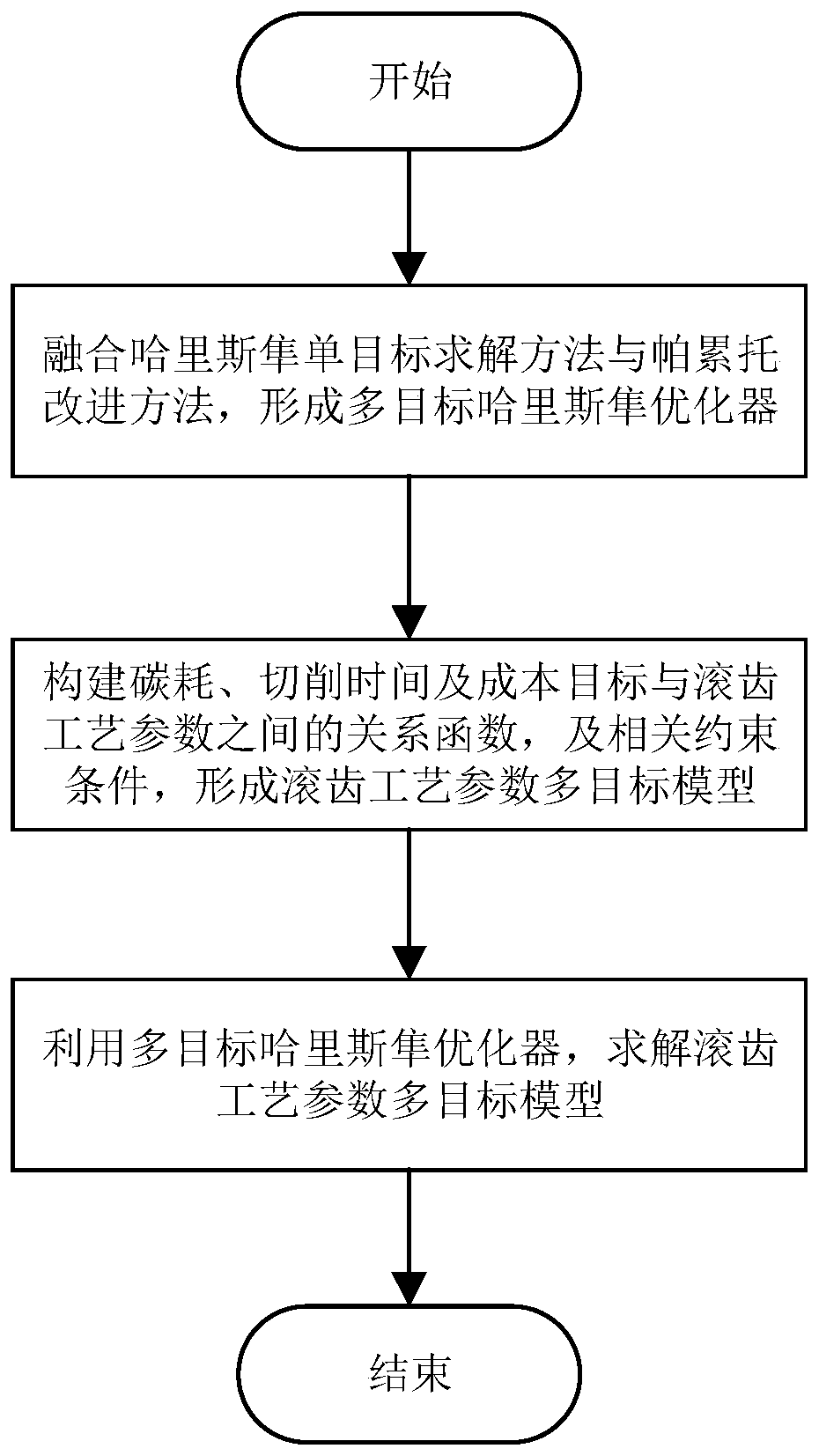

Hobbing parameter solving method based on multi-target Harris tenon optimizer

A Harris Falcon, multi-objective technology, applied in the field of gear hobbing parameters, can solve the problems of reducing cutting time, cost and carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

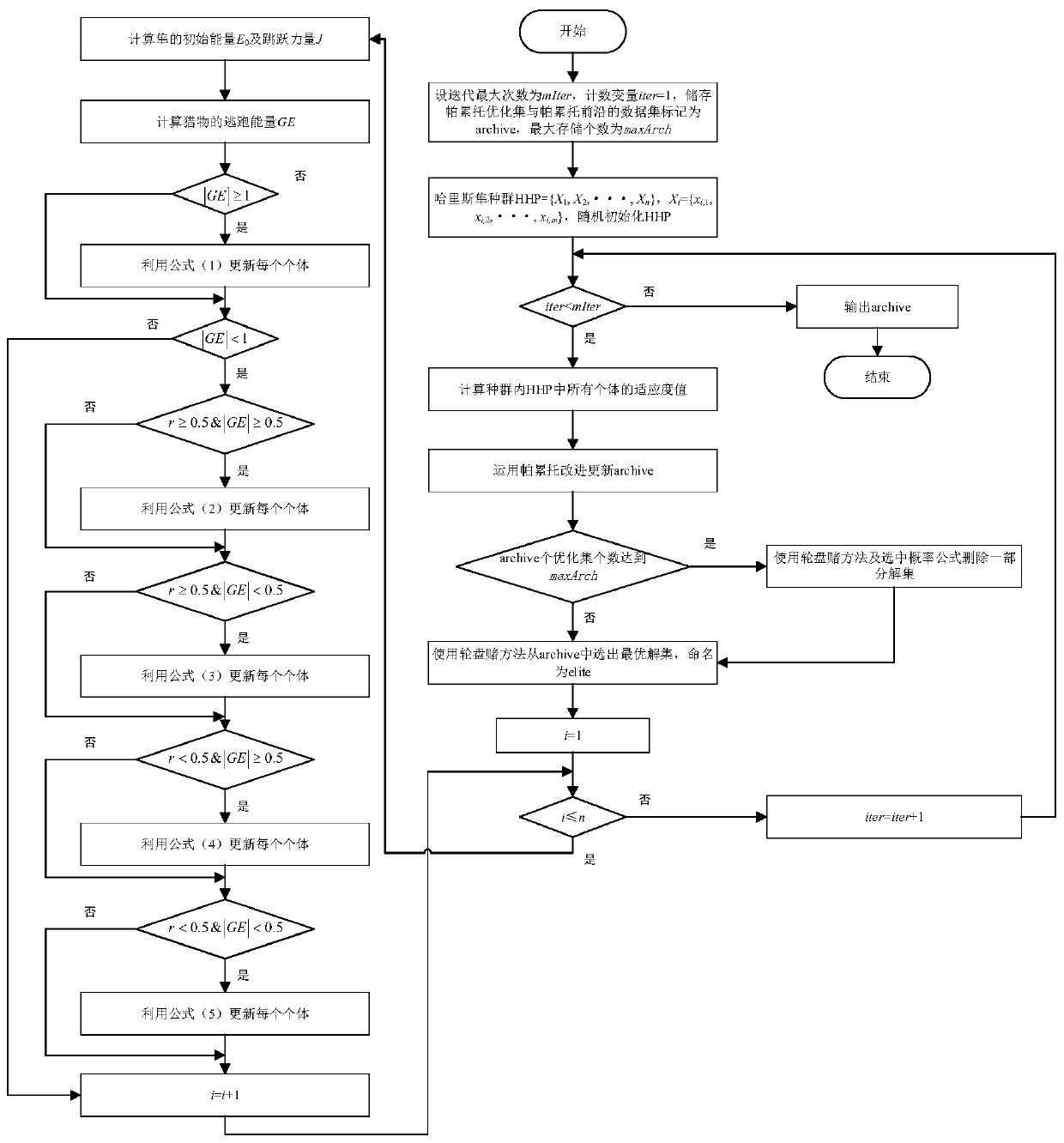

Method used

Image

Examples

Embodiment

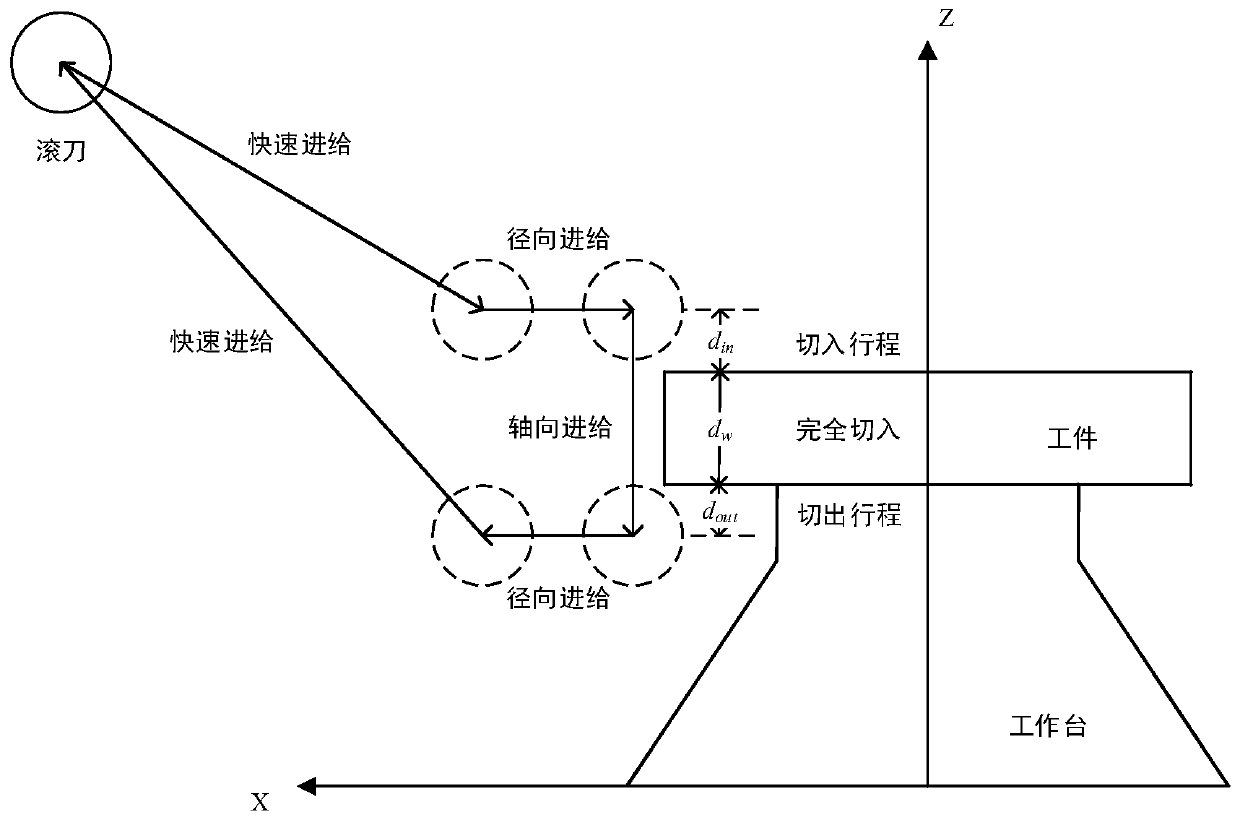

[0104] Take the gear processed by the six-axis four-link CNC high-speed gear hobbing machine YS3120CNC6 as an example. The gear type is cylindrical helical gear, the workpiece material is 20CrMo, the Brinell hardness is 190HBW, the machining accuracy is 7 grades, the hobbing type is reverse rolling, and the modulus is m 1 2mm, the normal pressure angle α is 20°, the number of teeth gz 1 is 41, installation angle η is 24.16°, tooth width d w 13mm, diameter d a1 94.011 mm, hob diameter d a0 is 71mm, the number of hob heads is z 0 is 2, full tooth height h 2 It is 4.005mm, one pass, and the software used is MATLAB. According to the specific steps of the present invention, the solution of the gear hobbing process parameters is carried out, the maximum number of iterations mIter is set to 100, and s is obtained according to manual experience 1min =351.5r / min, s 1max =388.5r / min, s 2min =1.66mm / r, s 2max =1.83mm / r, obtained by using response surface method and Design-Expert ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap