Energy servitization system of multi-machine production line and control method thereof

A production line and energy technology, applied in information technology support systems, instruments, data processing applications, etc., can solve the problems of energy loss in production lines, difficulties in reducing energy consumption, and large differences in energy requirements, so as to reduce energy consumption and improve energy efficiency , improve the effect of matching degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

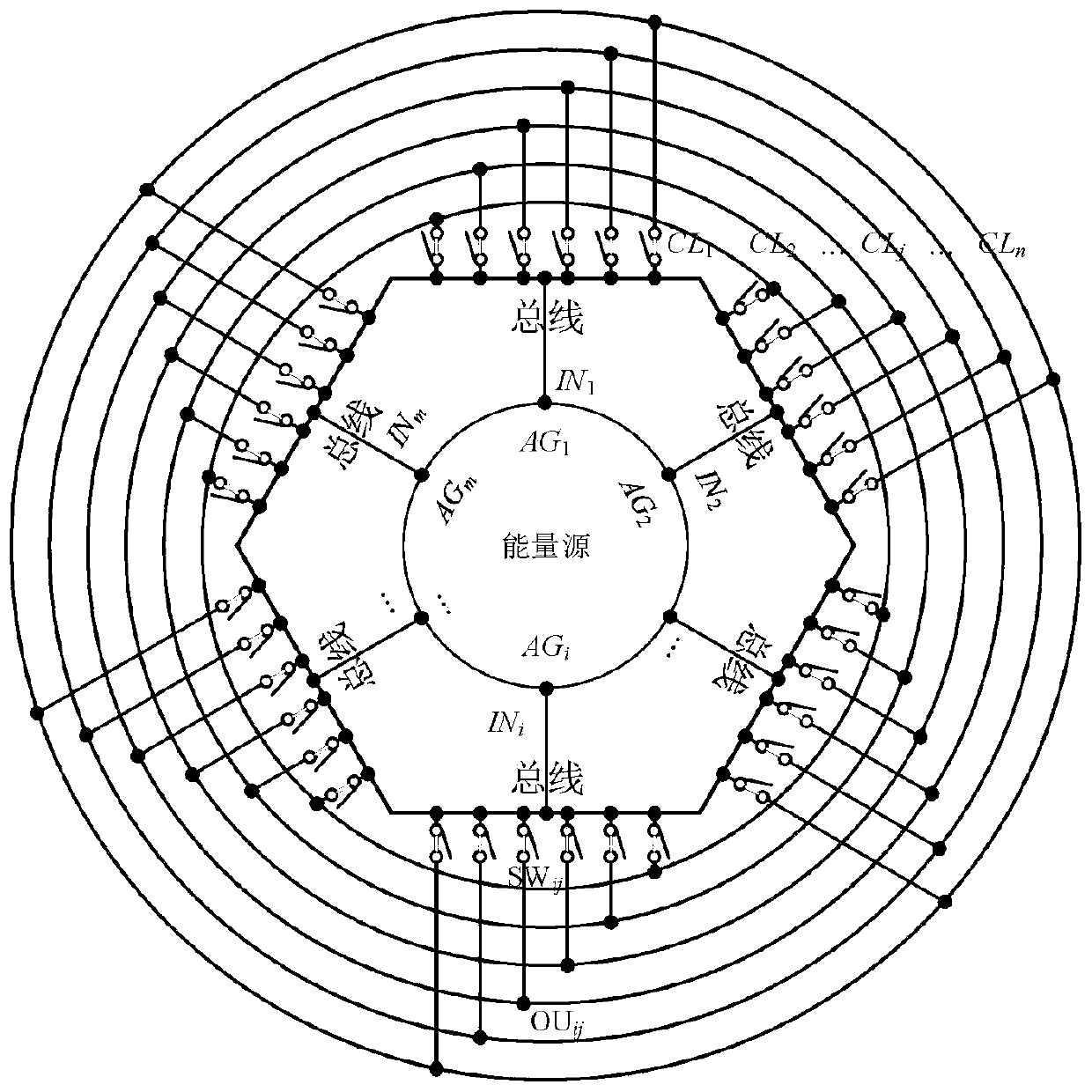

[0045] In this embodiment, an energy-as-a-service system for a multi-machine production line includes: a drive system, an execution device, an energy supply bus, and a control center;

[0046] The drive system is composed of m drive units AG={AG 1 ,AG 2 ,...,AG i ,...,AG m}, and used to provide energy for the actuator, where, AG i Indicates the i-th drive unit, i∈{1,2,...,m}; denote the i-th drive unit AG i The rated power of PR i ; The composition of the drive unit is configured according to the energy form required by the actuator, the output energy form can be hydraulic energy, mechanical energy, and the realization forms are motor-pump and electric motor respectively.

[0047] The execution device is composed of n execution units CL={CL 1 ,CL 2 ,...,CL j ,...,CL n}, and used to complete the processing tasks of the production line, where, CL j Indicates the jth execution unit, j∈{1,2,...,n}; the execution unit is the mechanical structure part of the machine tool. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com