Powder Conformal Volume Additive Method for Hot Forging Die Remanufacturing and Its Application

A hot forging die and remanufacturing technology, applied in the field of hot forging die repair and remanufacturing, to achieve the effect of ensuring bonding, grain refinement, and easy material composition and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Remanufacturing of invalid crankshaft forging die with powder conformal volume additive

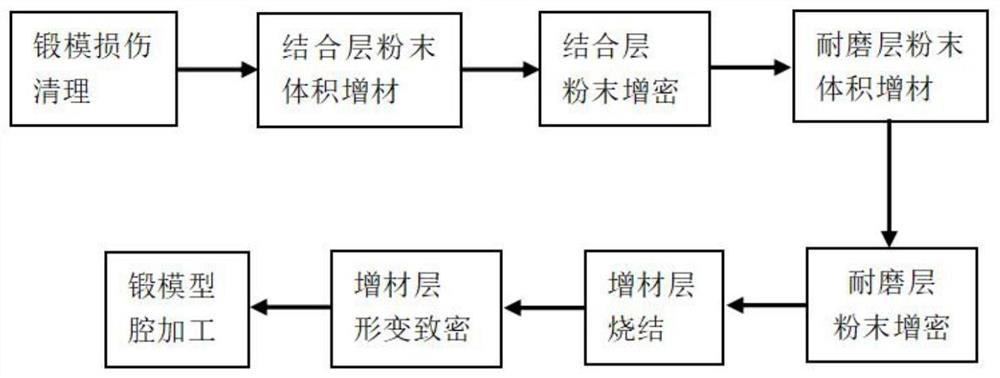

[0047] The specific process is as follows:

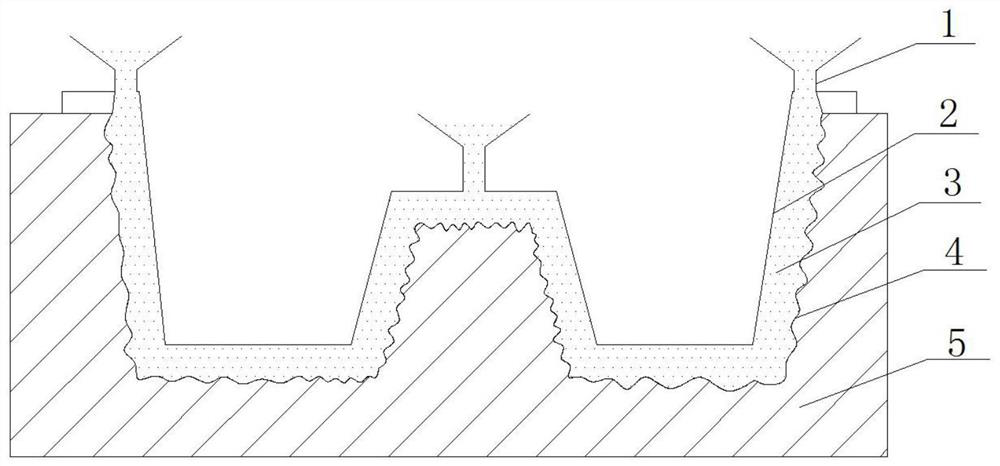

[0048] Step (a-1): Use a grinder to remove the scale and graphite emulsion in the cavity of the crankshaft forging model, and use carbon arc gouging to carefully clean the cavity area of the failed forging model to remove all defective layers. The damaged parts to be cleaned include the fatigue layer, cracks, wear, deformation and other areas of the cavity. The cleaning depth is 10-30mm, and the protruding area of the cavity is reduced or the concave area of the cavity is increased. Use imaging agent and penetrant to carry out coloring flaw detection on the cleaned cavity surface to detect whether defects such as cracks are completely removed.

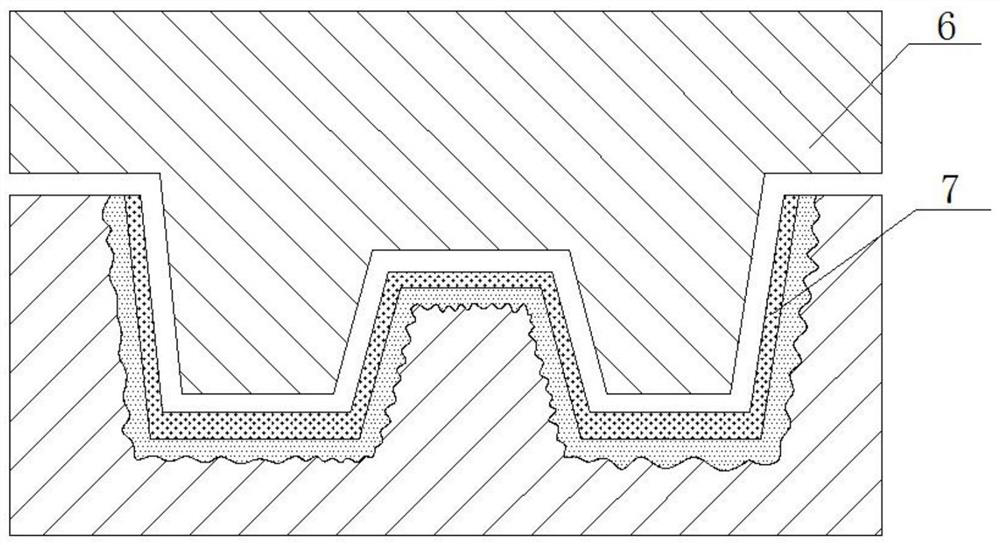

[0049] Step (b-1): According to the service performance requirements and material composition of the crankshaft forging die, the thickness of the bonding layer and the wear-resis...

Embodiment 2

[0056] Example 2 Remanufacturing of the failed connecting rod forging die with powder conformal volume additive

[0057] The specific process is as follows:

[0058] Step (a-1): Use a grinder to remove the oxide skin and graphite milk layer in the cavity of the forging model of the connecting rod, and use carbon arc gouging or a CNC machine tool to carefully clean the area of the cavity of the failed forging model to remove all defective layers. The damaged parts to be cleaned include the fatigue layer, cracks, wear, deformation and other areas of the cavity, and the cleaning depth is 10-30mm. Use imaging agent and penetrant to carry out coloring flaw detection on the cleaned cavity surface to detect whether defects such as cracks are completely removed.

[0059] Step (b-1): According to the service performance requirements of the hot forging die of the connecting rod, the thickness of the bonding layer and the wear-resistant layer and the composition of the powder material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com