Cutter device of decorative plate production line

A technology for decorative panels and production lines, which is applied in auxiliary devices, welding/cutting auxiliary equipment, welding/welding/cutting items, etc. shift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

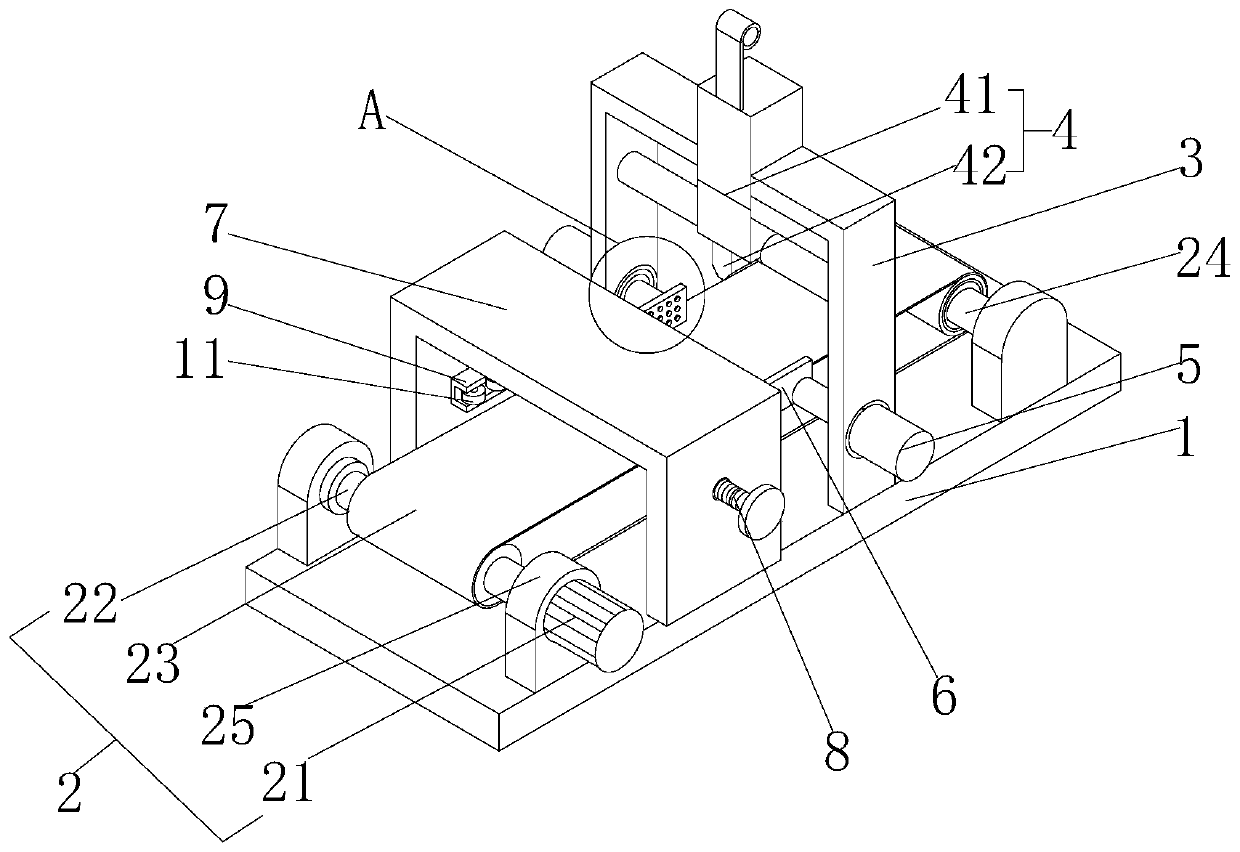

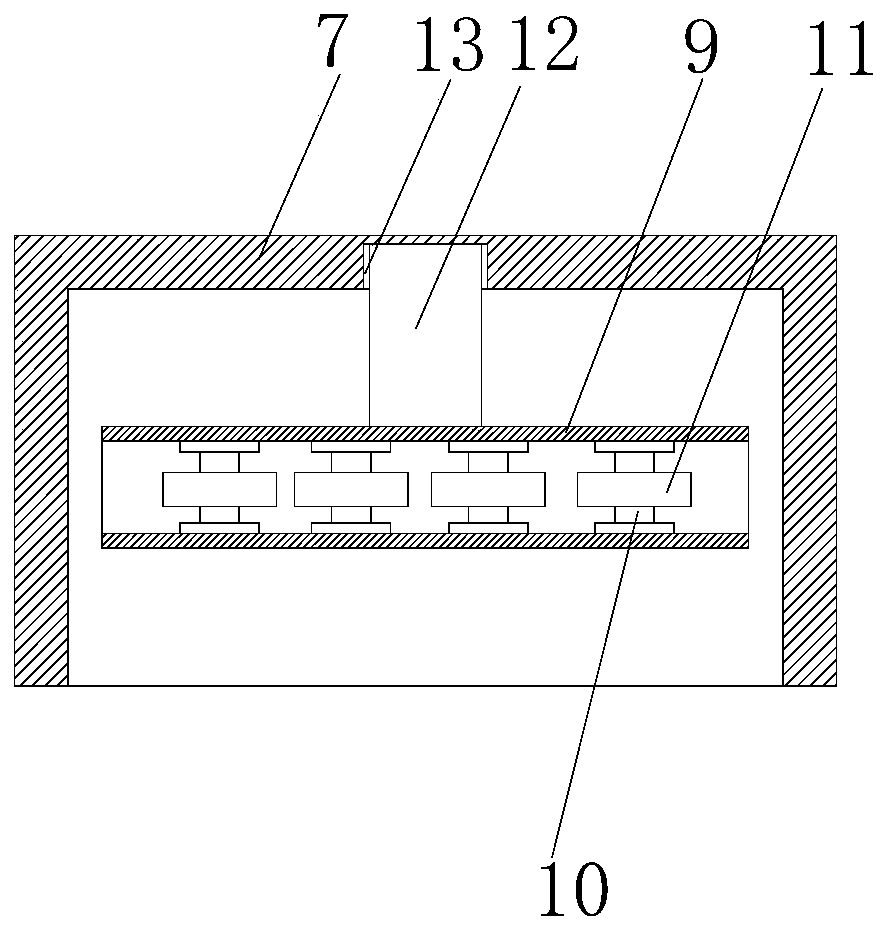

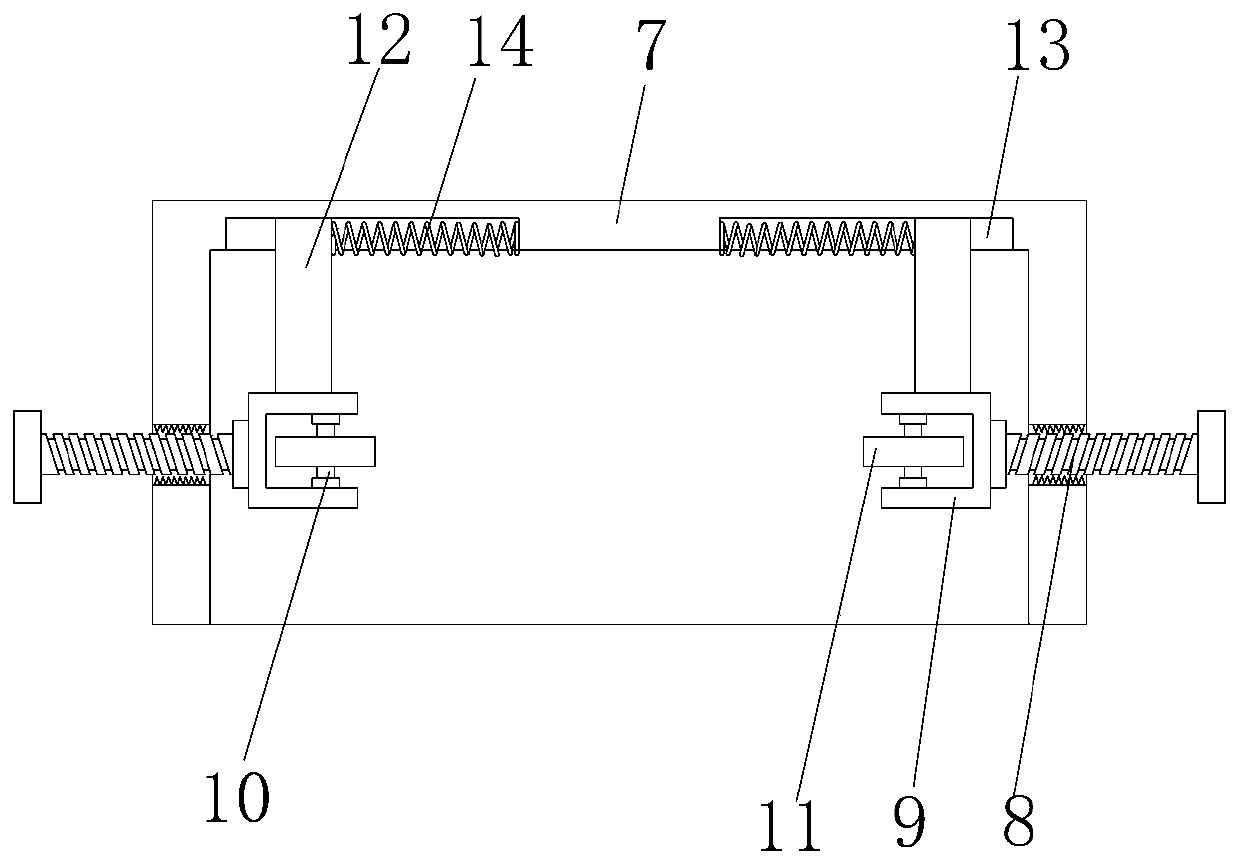

[0021] see Figure 1-4 , the cutter device of the decorative plate production line, including a support base 1, the top of the support base 1 is provided with a conveying assembly 2, the right side of the top of the support base 1 is welded with a gantry 3, and the top of the inner cavity of the gantry 3 is fixed with a laser cutting The knife machine 4 and the bottoms of the front and rear sides of the gantry 3 are fixedly connected with an electric cylinder 5, the telescopic end of the electric cylinder 5 runs through the gantry 3 and extends to the inner cavity of the gantry 3, and the telescopic end of the electric cylinder 5 is welded with a splint 6 , the top of the support base 1 and the left side of the gantry 3 are welded with a support frame 7, the front and rear sides of the support frame 7 are threaded with threaded rods 8, and the opposite side of the threaded rods 8 runs through the support frame 7 and extends to The inner cavity of the support frame 7, the oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com