Non-equal-thickness drum brake pad outer arc grinding production line with automatic feeding and discharging functions

A technology of automatic discharge device and brake pad, which is applied in the direction of grinding feed motion, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of low grinding accuracy, low production efficiency, and easy occurrence of defective products , to achieve a high degree of automation, reduce labor costs, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

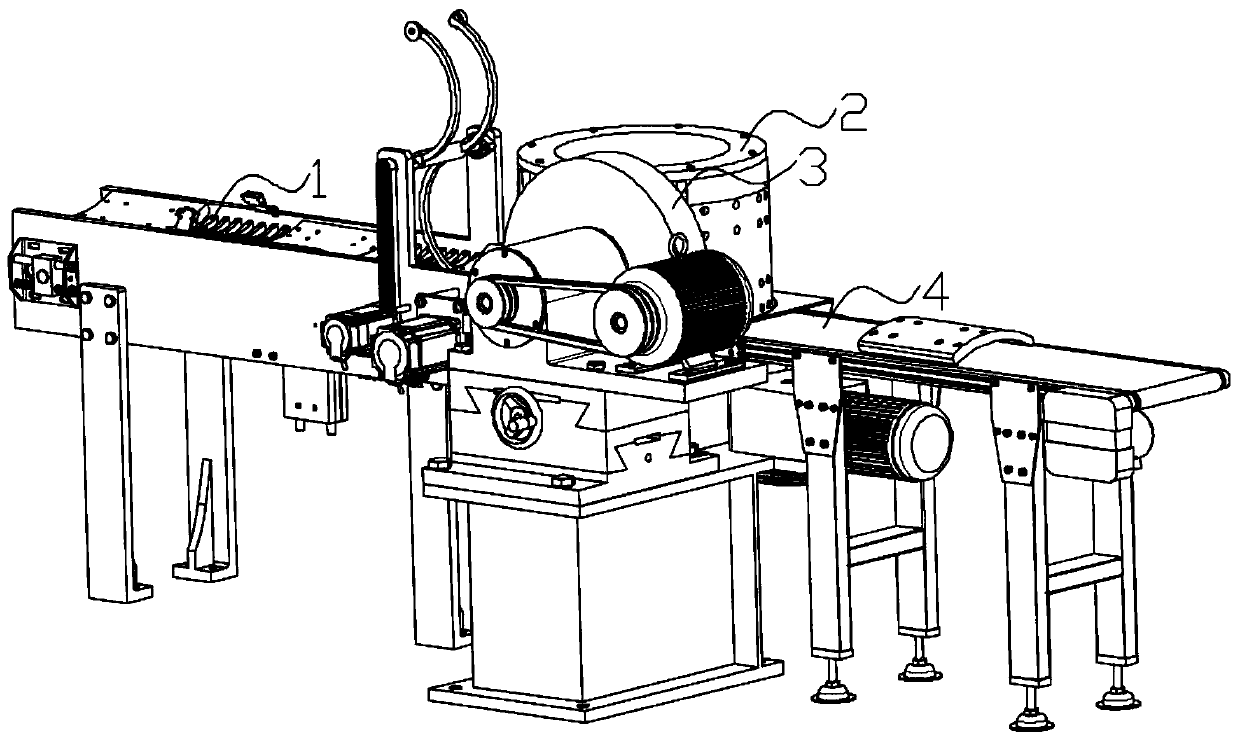

[0032] A non-equal thickness drum brake pad external arc grinding production line with automatic feeding and discharging, including a feeding device 1 , a positioning feeding device 2 , a grinding device 3 and an automatic discharging device 4 .

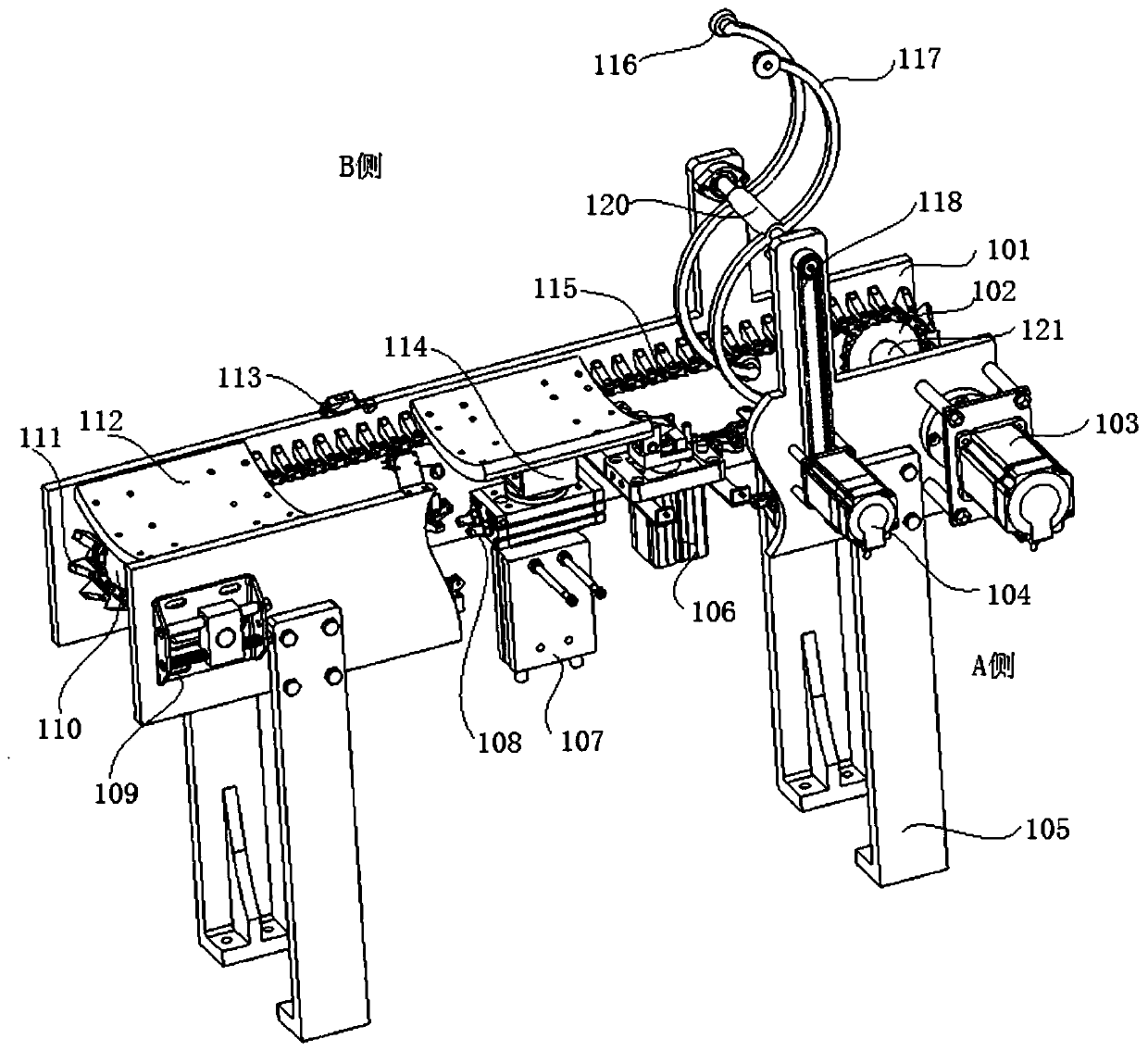

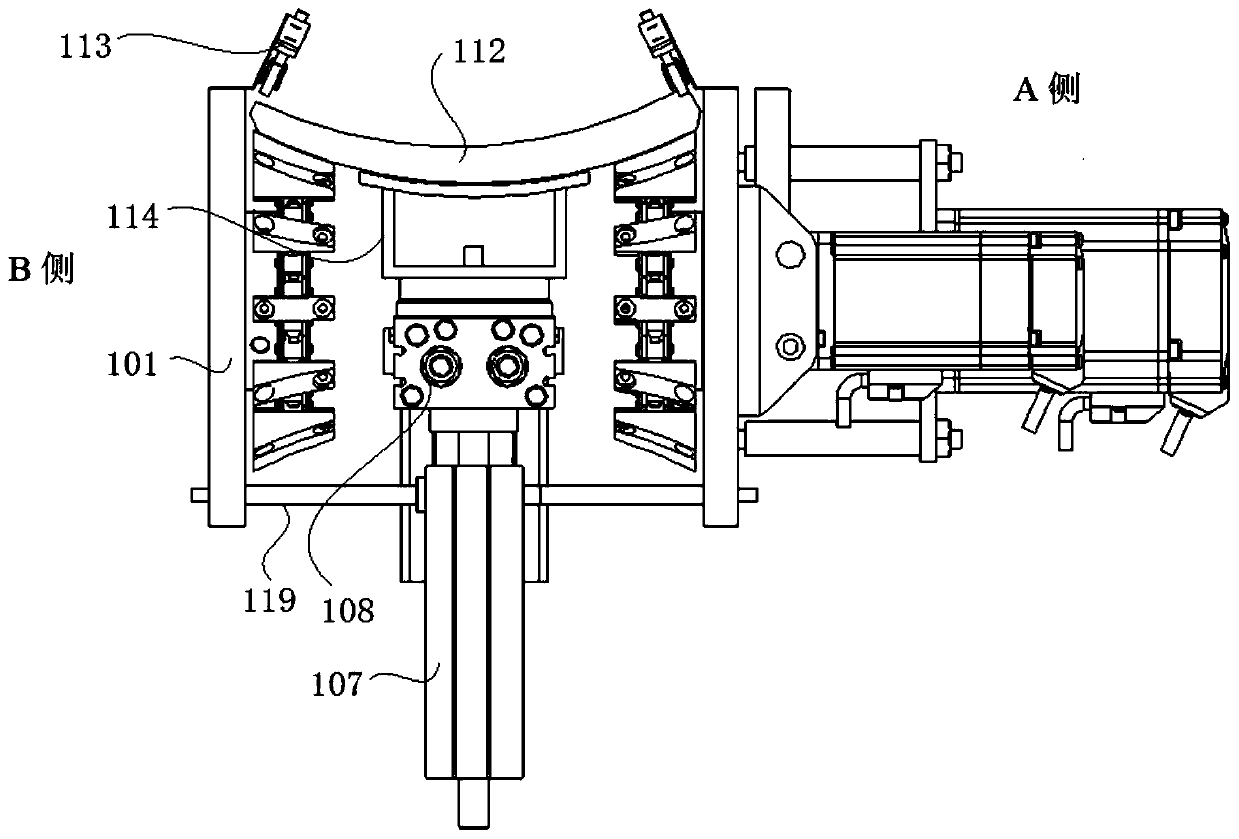

[0033] see figure 1 and figure 2 , the feeding device is used to transfer the brake pads to the positioning feeding device, and adjust the thick surface of the brake pads to the side away from the servo motor (side B), and the feeding device includes two oppositely arranged feeding Side plate 101, drive sprocket 102, feeding servo motor 103, vertical sheet servo motor 104, drive shaft 121, described feeding side plate 101 is fixed with the ground by foot 105; Described driving sprocket is arranged on feeding side plate The driven sprocket is arranged at the other end of the feed side plate, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com