Diacetyl acyclovir production solvent recovery method and solvent recovery device

A diacetyl acyclovir, solvent recovery device technology, applied in the field of solvent recovery, can solve the problems of inability to achieve clean production, failure of solvent recovery and mechanical application, etc., to achieve the effect of reducing production costs and reasonable treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

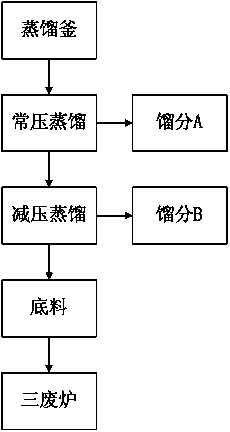

[0029] A kind of diacetyl acyclovir production solvent recovery method, comprises the following steps:

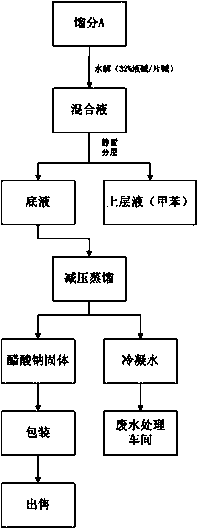

[0030] (1) Recover fraction A from the waste liquid obtained during the production of diacetyl acyclovir at a temperature of 128±2°C and a pressure of normal pressure; fraction A contains toluene, acetic anhydride, and acetic acid.

[0031] (2) After fraction A is recovered, the bottom material is obtained; the bottom material is subjected to vacuum distillation, and fraction B is collected at a temperature of 140±2°C and a pressure of -0.098MPa; in fraction B, 2-oxa- The mass fraction of 1,4-butanediol diethyl ester≥98.6%;

[0032] (3) When there is no obvious distillate, stop heating, turn on the circulating water to cool down to 75±2°C, discharge the remaining materials, and transfer the solid residue to the three-waste furnace for incineration.

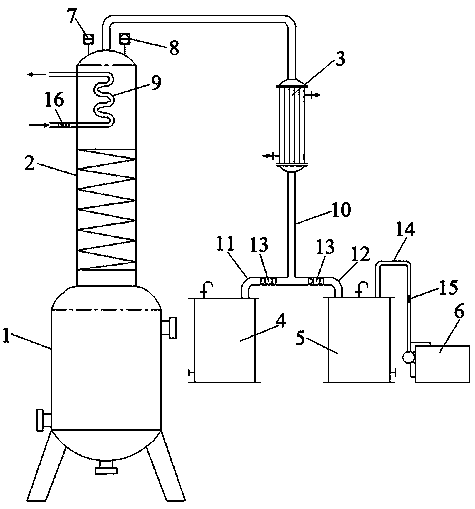

[0033] The process flow chart of above-mentioned solvent recovery method is as figure 1 As shown, the solvent recovery devi...

Embodiment 2

[0036] A kind of diacetyl acyclovir production solvent recovery method, comprises the following steps:

[0037] (1) Recover fraction A from the waste liquid obtained during the production of diacetyl acyclovir at a temperature of 122±2°C and a pressure of normal pressure; fraction A contains toluene, acetic anhydride, and acetic acid.

[0038] (2) After fraction A is recovered, the bottom material is obtained; the bottom material is subjected to vacuum distillation, and fraction B is collected at a temperature of 132±2°C and a pressure of -0.098MPa; in fraction B, 2-oxa- The mass fraction of 1,4-butanediol diethyl ester≥98.1%;

[0039] (3) When there is no obvious distillate, stop heating, turn on the circulating water to cool down to 72±2°C, discharge the remaining materials, and transfer the solid residue to the three-waste furnace for incineration.

[0040] The solvent recovery device corresponding to the above solvent recovery method may be any suitable solvent recovery d...

Embodiment 3

[0043] A kind of diacetyl acyclovir production solvent recovery method, comprises the following steps:

[0044] (1) Recover fraction A from the waste liquid obtained during the production of diacetyl acyclovir at a temperature of 126±2°C and a pressure of normal pressure; fraction A contains toluene, acetic anhydride, and acetic acid.

[0045](2) After fraction A is recovered, the bottom material is obtained; the bottom material is subjected to vacuum distillation, and fraction B is collected at a temperature of 143±2°C and a pressure of -0.098MPa; in fraction B, 2-oxa- The mass fraction of 1,4-butanediol diethyl ester is ≥98.5%;

[0046] (3) When there is no obvious distillate, stop heating, turn on the circulating water to cool down to 78±2°C, discharge the remaining materials, and transfer the solid residue to the three-waste furnace for incineration.

[0047] The solvent recovery device corresponding to the above solvent recovery method may be any suitable solvent recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com