Method for preparing bricks from heavy metal sludge by using wet method

A heavy metal sludge and heavy metal technology, applied in clay products, applications, household appliances, etc., to avoid energy consumption, realize safe resource utilization, and achieve multi-win effects of ecological and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Raw materials: sewage treatment plant sludge, with a moisture content of 90%; clay with a moisture content of 8%.

[0021] 2. Process steps

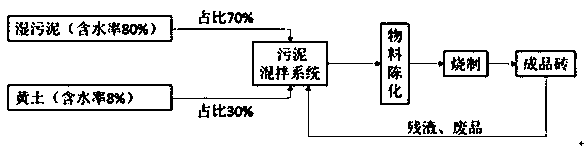

[0022] figure 1 It is the process flow of the method for making heavy metal sludge wet bricks.

[0023] 1) Material formula (mass percentage): Control the dosage of domestic sludge at 70%, and the dosage of clay at 30%.

[0024] 2) Mixing: Put the mixture in a planetary mixer and adjust the mixing time appropriately.

[0025] 3) Aging: Place the material in a natural ventilated place for aging for 5 days, mechanically turning 4 times during aging, and the moisture content of the mixture after aging is 20%.

[0026] 4) Press molding: Put the aged material into the mold, and press it into molding with a molding pressure of 10MPa.

[0027] 5) Drying of the bricks: Put the bricks in the room temperature and dry in the shade for 4 days, and then dry them at 105°C for 24 hours.

[0028] 6) High-temperature roasting: Raise from room temperature to...

Embodiment 2

[0034] 1. Raw materials: sludge from domestic sewage treatment plant, with a moisture content of 50%; clay with a moisture content of 10%.

[0035] 2. Process steps

[0036] 1) Material formula (mass percentage): control the domestic sludge content to 10% and clay content to 90%.

[0037] 2) Mixing: Put the mixture in a planetary mixer and adjust the mixing time appropriately.

[0038] 3) Aging: The material is aged in a natural ventilated place for 2 days. During the aging period, it is mechanically turned 3 times. The moisture content of the aging mixture is 18%.

[0039] 4) Press molding: Put the aged material into the mold, and press it into molding with a molding pressure of 10MPa.

[0040] 5) Drying of the bricks: Put the bricks in the room temperature and dry in the shade for 4 days, and then dry them at 105°C for 24 hours.

[0041] 6) High-temperature roasting: Raise from room temperature to 200°C and stay at 200°C for 1h; then heat up from 200°C to 600°C and stay at 600°C for 1.5...

Embodiment 3

[0047] 1. Raw materials

[0048] 1) Heavy metal sludge: 70% moisture content

[0049] 2) Clay: 9% moisture content

[0050] Table 1 below shows the heavy metal element content (unit: mg / kg) in the heavy metal sludge and clay in this case.

[0051] Table 1 Heavy metal content in heavy metal sludge and clay (unit: mg / kg)

[0052] projectCu Zn Ni CdCr Pb Heavy metal sludge9749.84813.231643.39169.3624770.30742.18 clay36.5988.6215.520.4175.8516.71

[0053] 2. Process steps

[0054] 1) Material formula (mass percentage): Control the mixing amount of heavy metal sludge to 40%, and the mixing amount of clay to 60%.

[0055] 2) Mixing: Put the mixture in a planetary mixer and adjust the mixing time appropriately.

[0056] 3) Aging: Place the material in a natural ventilated place for 4 days, mechanically turning 4 times during the aging, and the moisture content of the mixture after aging is 19%.

[0057] 4) Press molding: Put the aged material into the mold, and press it into molding with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com