Second-kind lithium bromide absorption heat pump unit system

A lithium bromide absorption and heat pump unit technology, which is applied in the direction of adsorption machines, machines using waste heat, refrigerators, etc., can solve the problems that waste heat cannot be recycled, the total amount of waste heat is reduced, and energy consumption is increased, so as to achieve a comprehensive economy of energy saving and emission reduction and social benefits, reducing primary energy consumption, and improving the grade of high-temperature heat sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

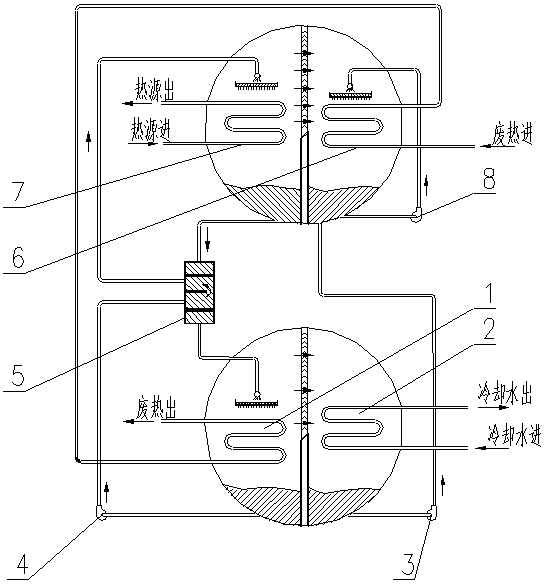

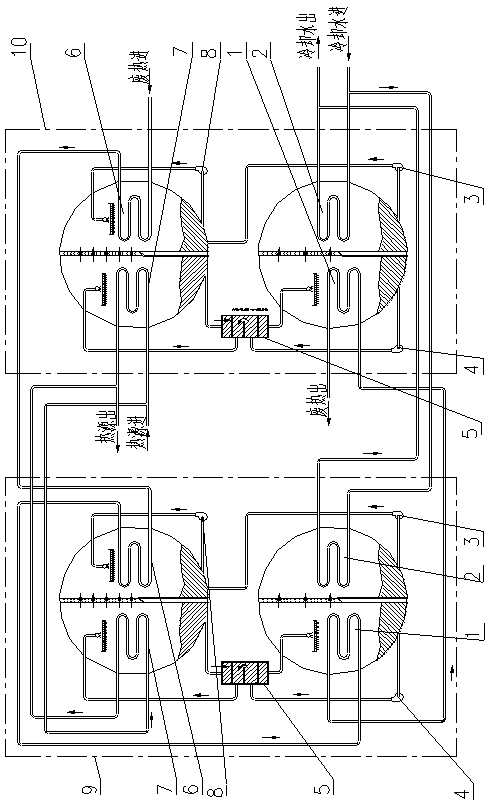

[0022] Such as figure 2 As shown, a second-type lithium bromide absorption heat pump unit system is composed of two single-effect second-type lithium bromide absorption heat pump units connected by pipelines, the first single-effect second-type lithium bromide absorption heat pump unit 9 and the second Two single-effect second-type lithium bromide absorption heat pump units 10 each include a generator 1, a condenser 2, an evaporator 6, an absorber 7, a solution heat exchanger 5, a concentrated solution pump 4, a refrigerant pump 3, and an evaporator cooling Agent circulation pump 8, control system (not shown in the figure) and pipelines connecting various components, etc. Drive waste heat sources in series and divide them into three temperature zones, namely high temperature zone, medium temperature zone and low temperature zone. The waste heat sources are driven in series to enter the evaporator 6 of the first single-effect second-type lithium bromide absorption heat pump u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com