Intelligent padding operation device

An operating device and intelligent technology, applied in the field of tanning, can solve problems such as affecting the working environment, affecting the finishing quality, reducing the working efficiency, etc., to achieve the effect of ensuring the quality of brushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

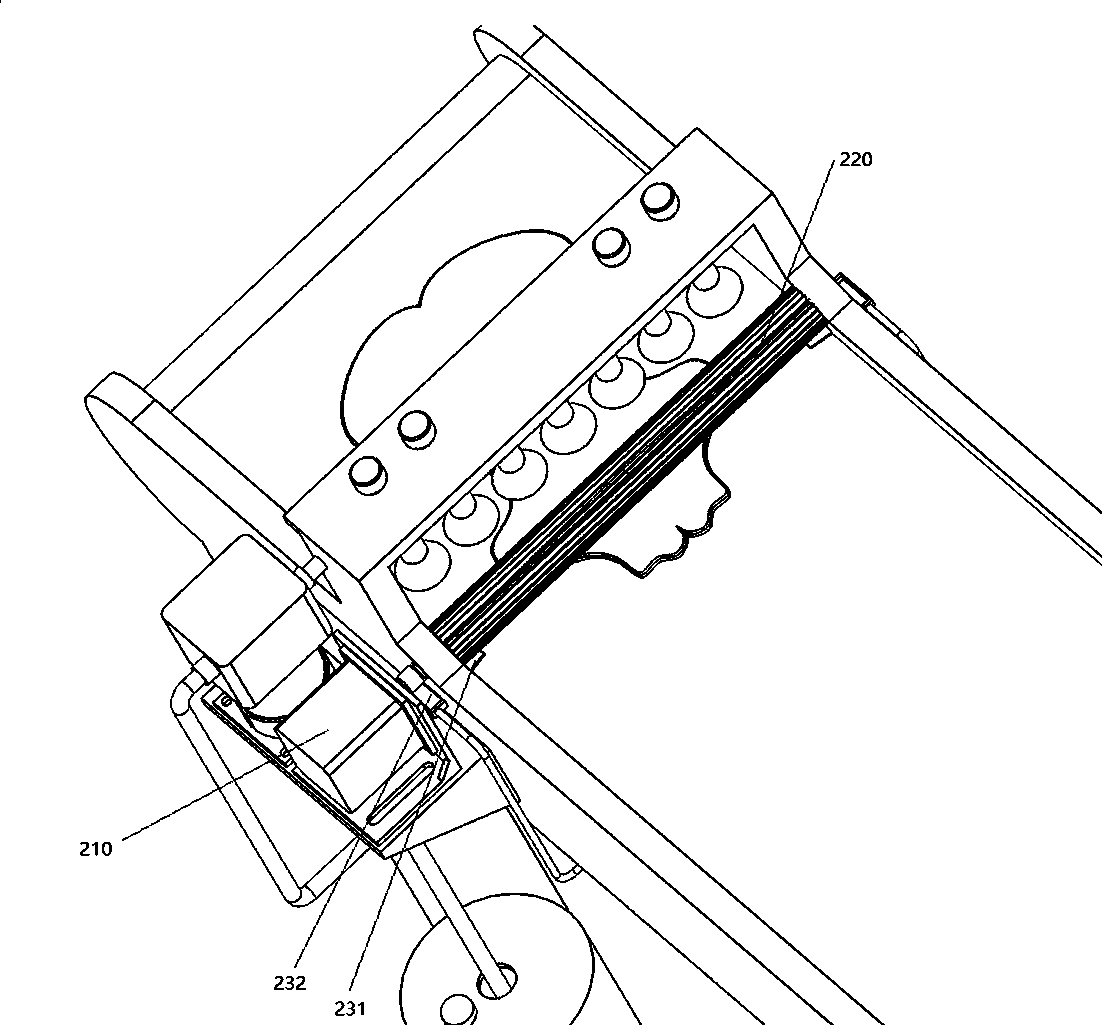

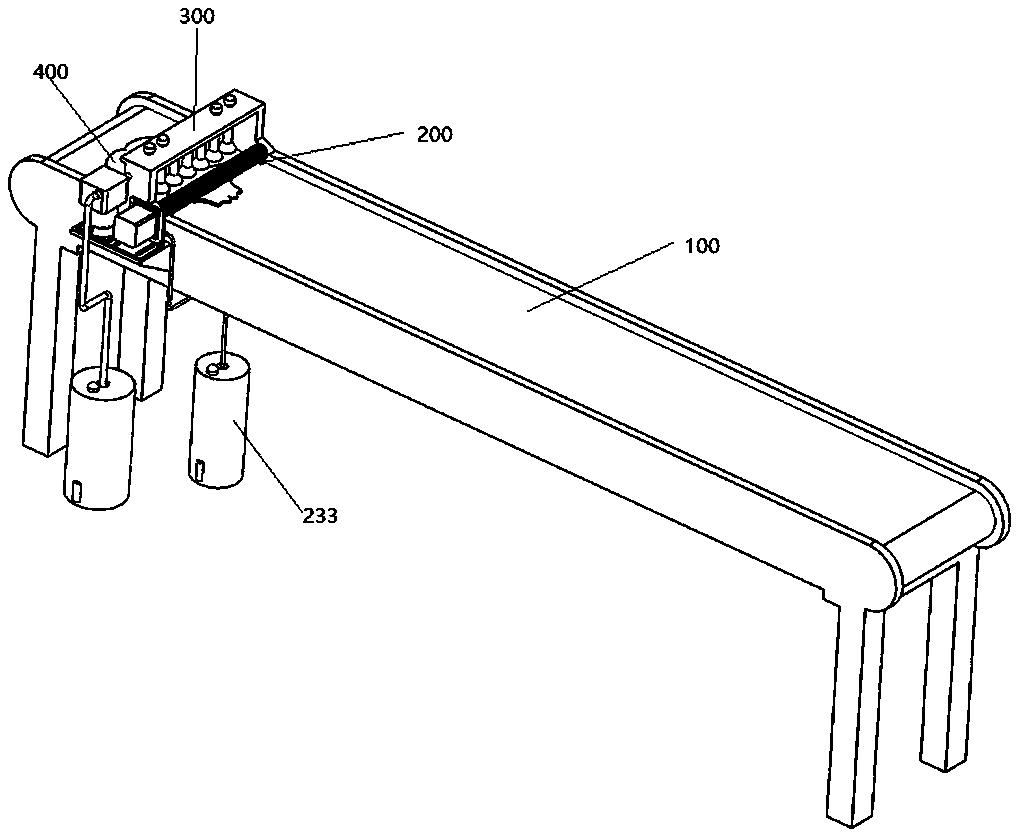

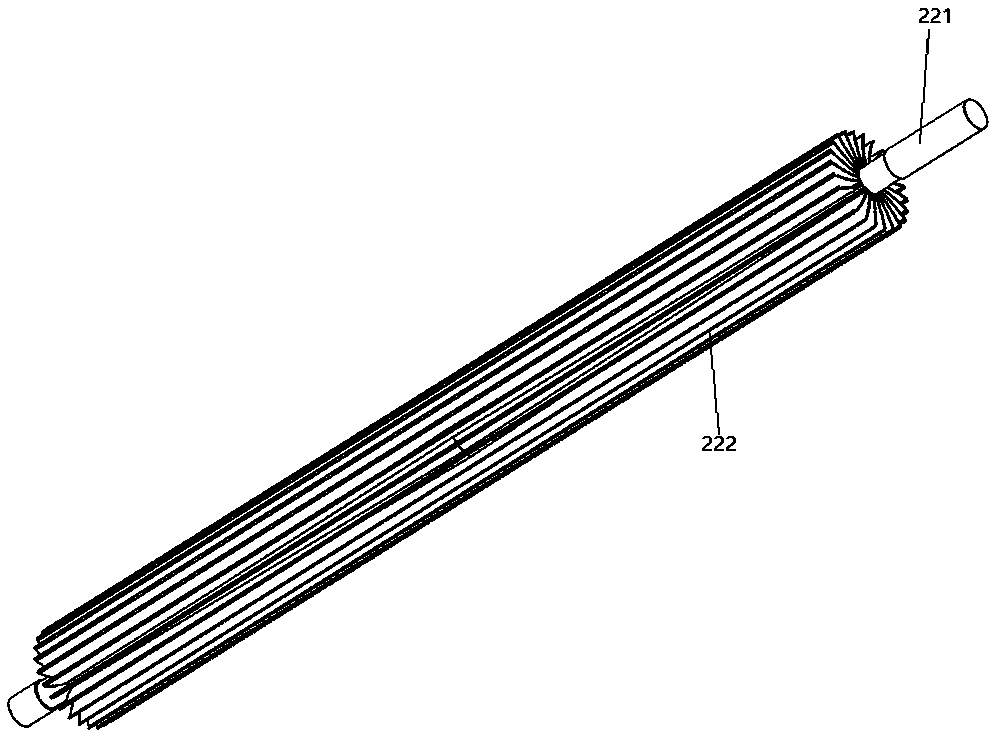

[0026] Such as Figure 1 to Figure 6 As shown, an intelligent pulp wiping operation device includes a conveyor belt 100 , a spraying mechanism 300 and a flexible roller mechanism 200 . The spraying mechanism 300 is used for intelligent spraying of the surface of the leather 400 conveyed by the conveyor belt 100. The flexible roller mechanism 200 is arranged behind the spraying mechanism along the conveying direction of the conveyor belt 100, and the color paste on the surface of the sprayed leather 400 is evenly applied. , to complete the pulping operation.

[0027] Such as figure 1 , Figure 6 As shown, the spraying mechanism 300 includes a color paste raw material barrel 310 , a motor b320 , a color paste pump 330 , an infrared sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com