Production method of high-whiteness waste paper deinking and bleaching paper pulp

A technology for deinking and producing waste paper, applied in the field of papermaking, can solve the problems of high cost of wood pulp, unable to achieve the purpose of reducing costs and green production, unable to produce high whiteness waste paper deinking and bleaching pulp, etc. The effect of material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

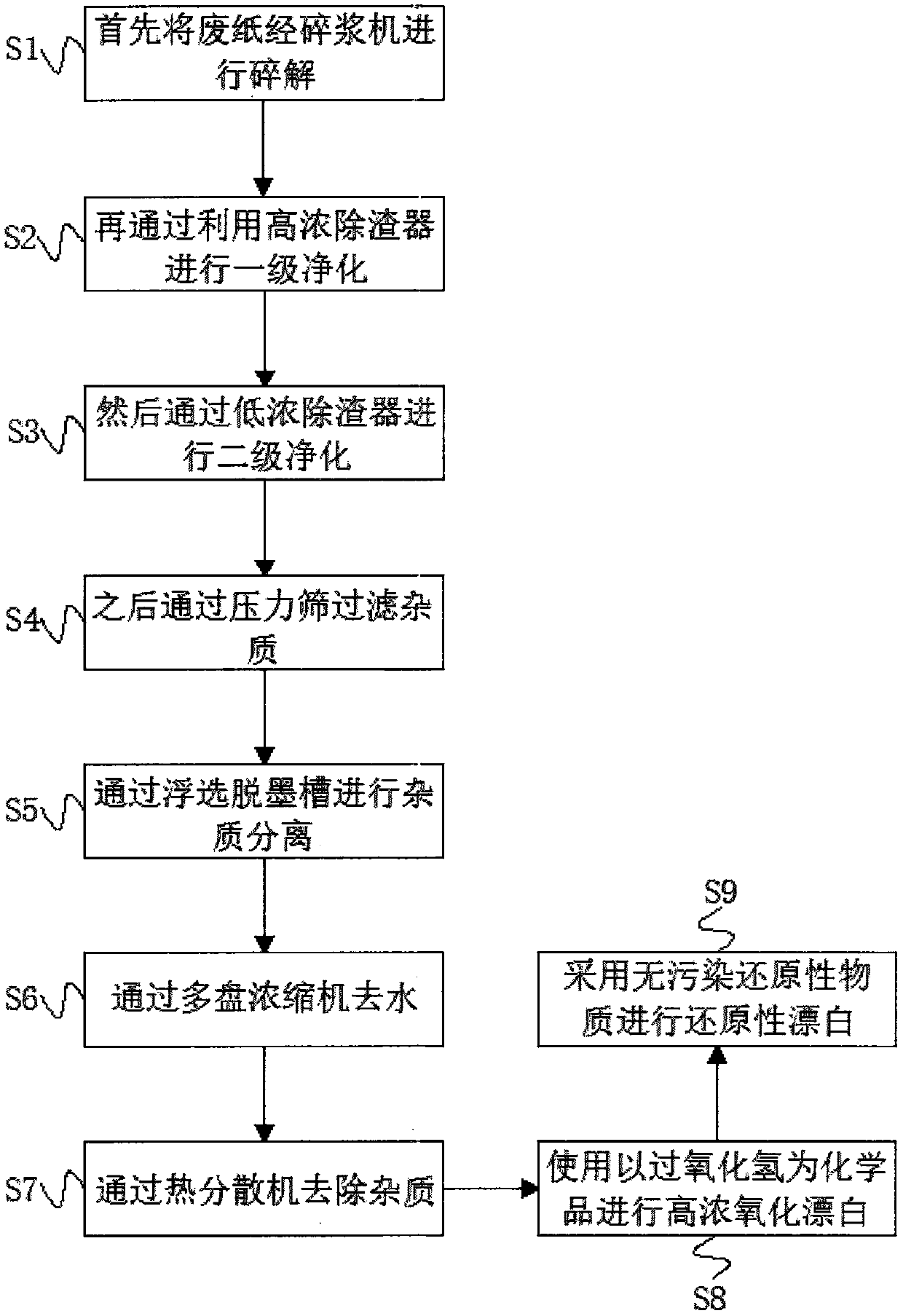

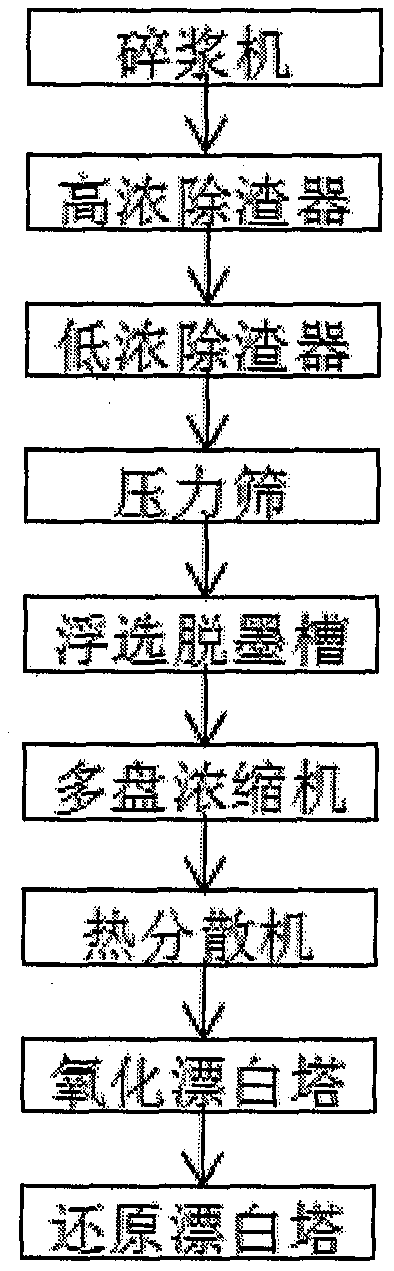

Method used

Image

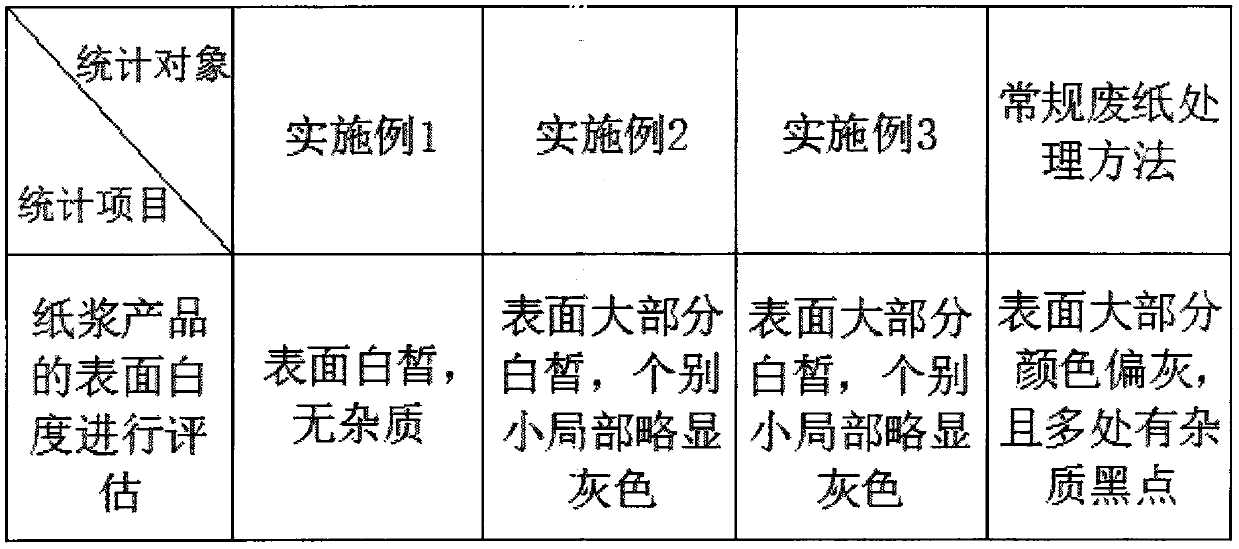

Examples

Embodiment 1

[0034] S1, first disintegrating the waste paper through a pulper, the pulper disintegrates the waste paper, and the pulping cutter head in the pulper fully disintegrates the waste paper fibers at a speed of 250r / min, thereby obtaining pulp;

[0035] S2, and then use the high-consistency slag remover to perform the first-stage purification. The high-concentration slag remover adopts a centrifugal rotation speed of 800r / min, and the heavy impurities with large density and large volume in the pulp are thrown to the wall of the device, under the action of gravity down, slide down the bottom of the device, and enter the sediment tank to complete the first-level purification of the high-concentration slag remover;

[0036] S3. Then carry out secondary purification through the low-consistency cleaner. The low-concentration cleaner uses a centrifugal speed of 450r / min to separate the heavy impurities with high density and small volume in the pulp to complete the removal of the low-conc...

Embodiment 2

[0044] S1, first disintegrate the waste paper through a pulper, and the pulper disintegrates the waste paper, and the pulping cutter head in the pulper fully disintegrates the waste paper fibers at a speed of 200r / min, thereby obtaining pulp;

[0045] S2. Then use the high-consistency slag remover to perform the first-stage purification. The high-concentration slag remover adopts a centrifugal rotation speed of 700r / min, and the heavy impurities with large density and large volume in the pulp are thrown to the wall of the device, under the action of gravity down, slide down the bottom of the device, and enter the sediment tank to complete the first-level purification of the high-concentration slag remover;

[0046] S3. Then carry out secondary purification through the low-concentration cleaner. The low-concentration cleaner adopts a centrifugal speed of 400r / min to separate the heavy impurities with high density and small volume in the pulp to complete the removal of the low-co...

Embodiment 3

[0054] S1, first disintegrate the waste paper through a pulper, and the pulper disintegrates the waste paper, and the pulping cutter head in the pulper fully disintegrates the waste paper fibers at a speed of 300r / min, thereby obtaining pulp;

[0055] S2, and then use the high-consistency slag remover to perform the first-stage purification. The high-concentration slag remover adopts a centrifugal rotation speed of 900r / min, and the heavy impurities with large density and large volume in the pulp are thrown to the wall of the device, under the action of gravity down, slide down the bottom of the device, and enter the sediment tank to complete the first-level purification of the high-concentration slag remover;

[0056] S3. Then carry out secondary purification through the low-consistency cleaner. The low-concentration cleaner uses a centrifugal speed of 500r / min to separate the heavy impurities with high density and small volume in the pulp to complete the removal of the low-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com