Mining room goaf filling method

A technology for goafs and mine houses, applied in fillings, mining equipment, earthwork drilling, etc., can solve the problems of poor impermeability, wear resistance and durability, difficult to meet production requirements, and high water content of concrete, and achieves a high level of performance. Endurance strength, good gradation, reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

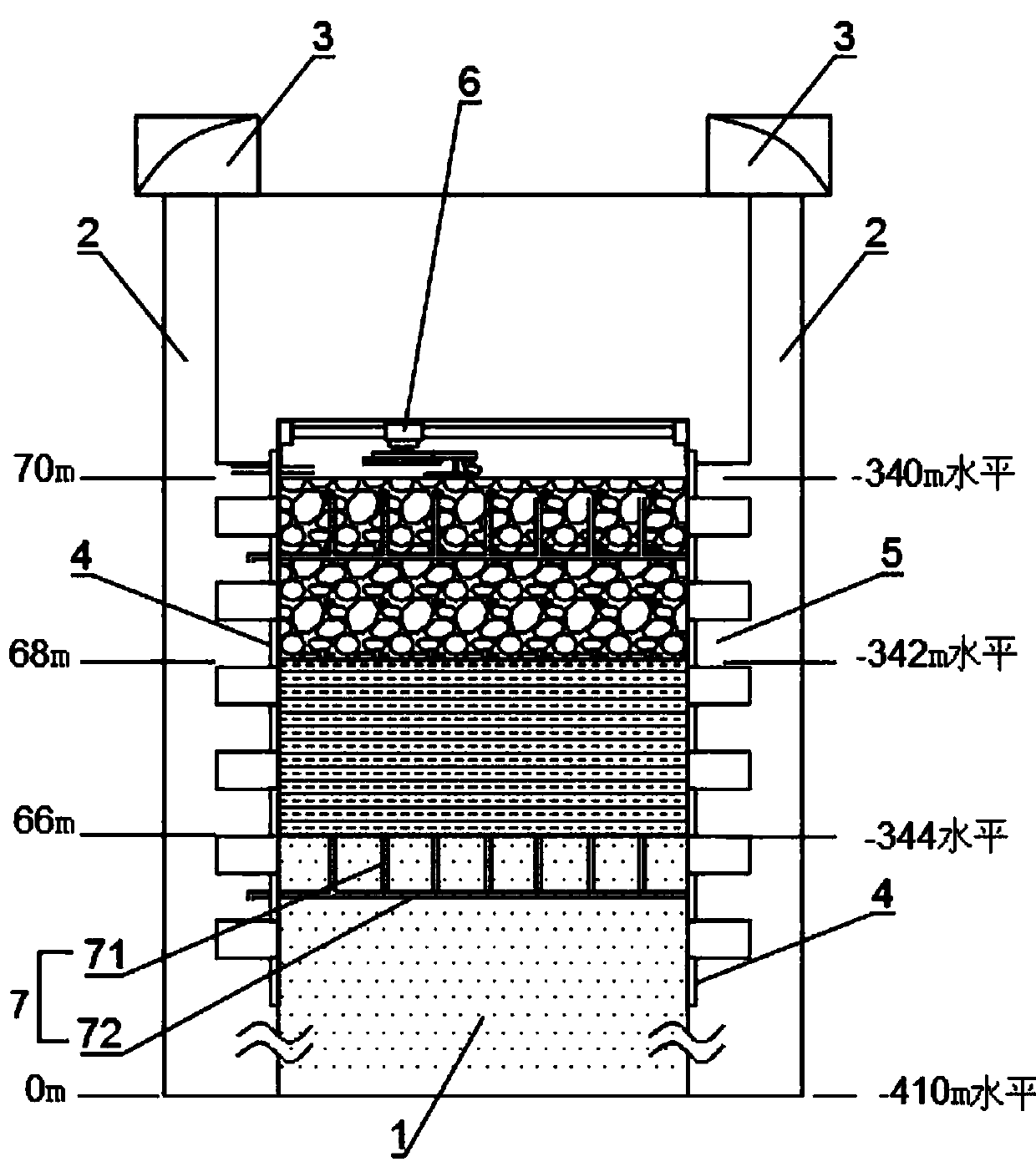

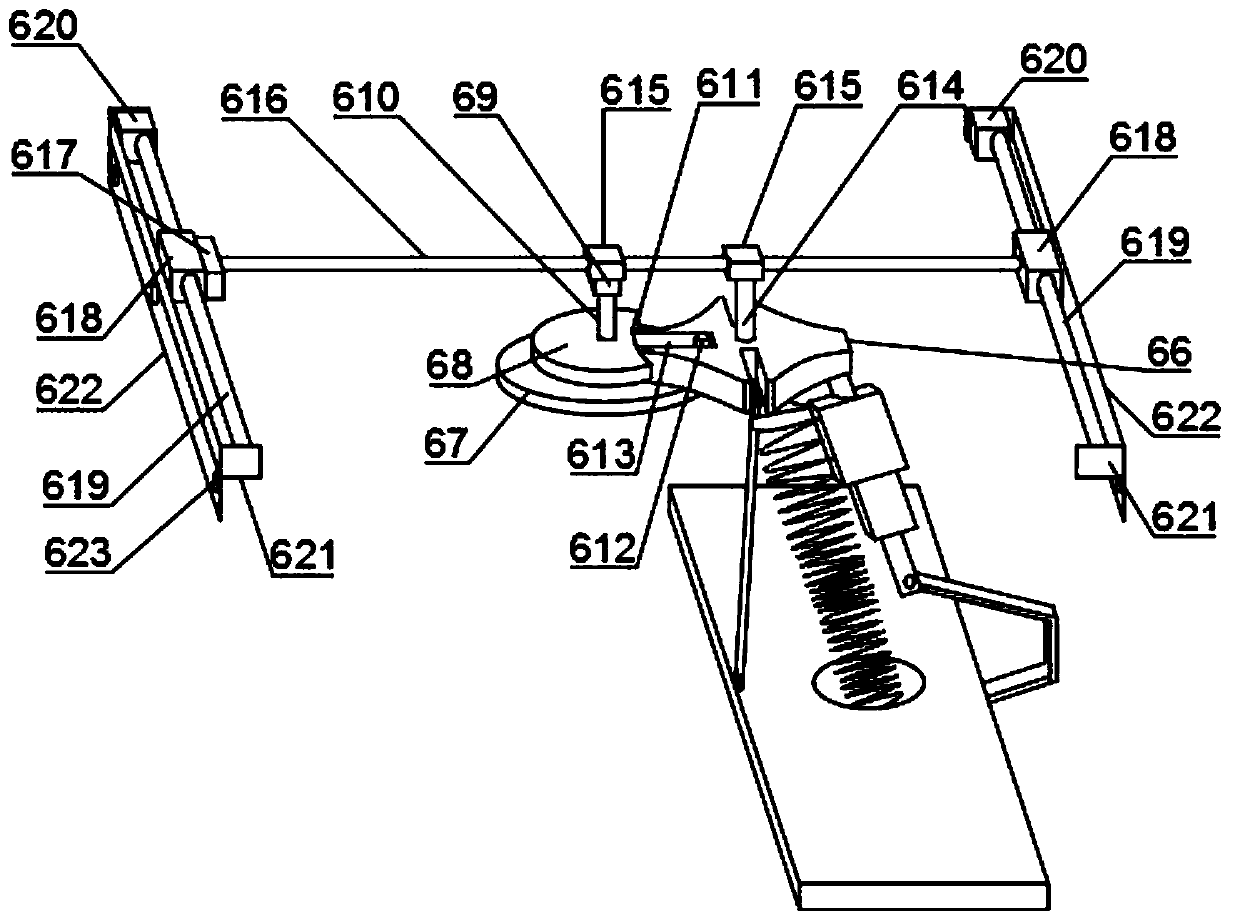

[0028] like Figure 1-5 As shown, the structural parameters of the mine house in this embodiment: the mine house is arranged along the ore body, the width of the mine house and the ore pillar is 40m, the length and the thickness of the ore body are 60m, and the stage height is 70m. The section heights are 23m, 23m, 24m, and the bottom structure of the stope is a cutting trench structure;

[0029] A method for filling goaf of a mining house, the filling material of the method is the mortar with full tailings, excavation gangue, and lime-sand ratio of 1:6; the method comprises:

[0030] (1) Measure the top and sides of the goaf;

[0031] (2) Full tailings non-cemented filling is used below 4m from the top of the filling body;

[0032] (3) For more than 4m above the top of the filling body, use excavation gangue and mortar cemented with a lime-sand ratio of 1:6 to fill and connect the roof, and the cementing material is cement powder:

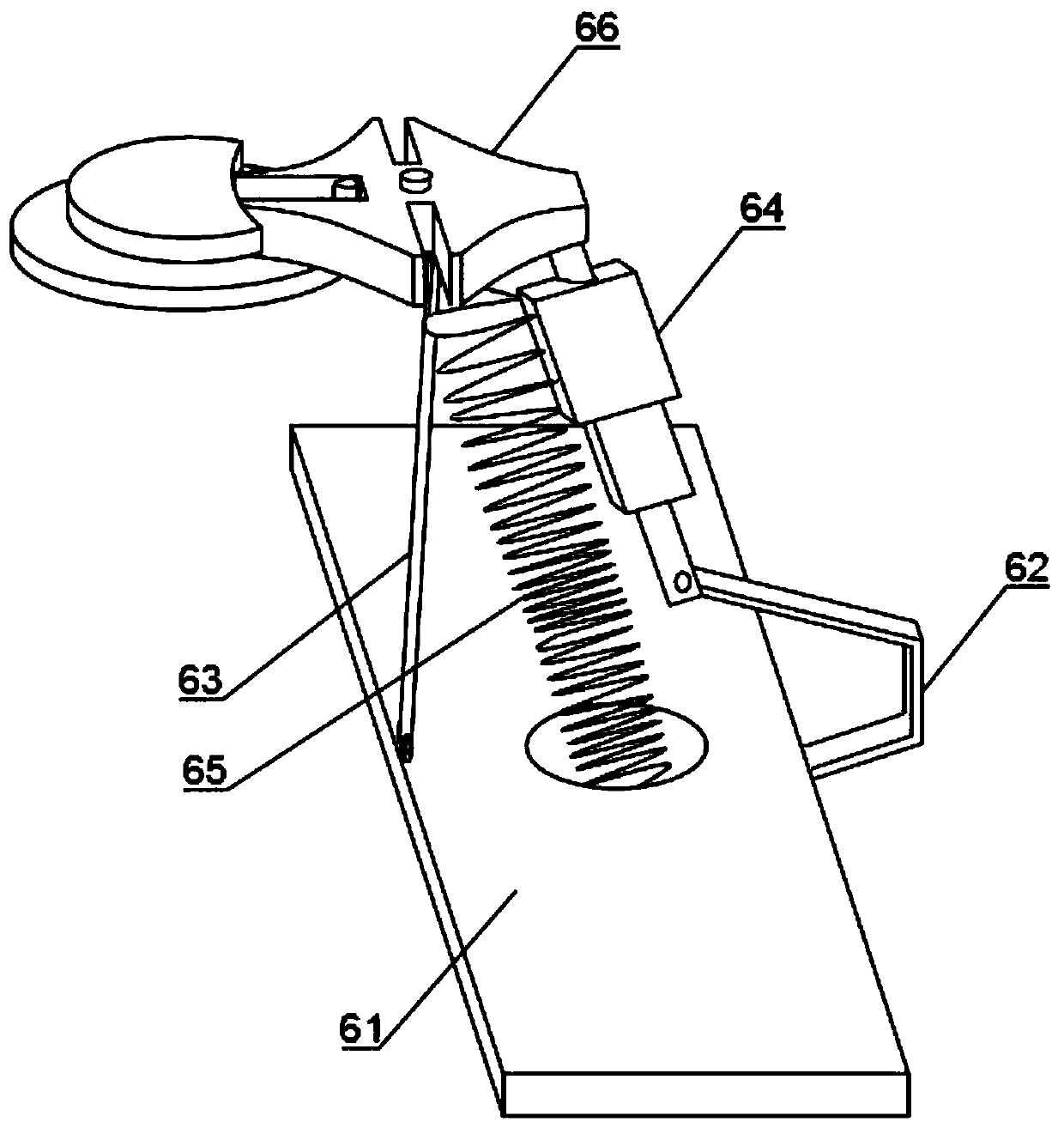

[0033] S1. Use mortar with a lime-sand r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com