Sub-module circuit for three-phase modular multilevel converter

A three-phase module and sub-module technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., to achieve the effect of facilitating unified production, reducing volume and cost, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples.

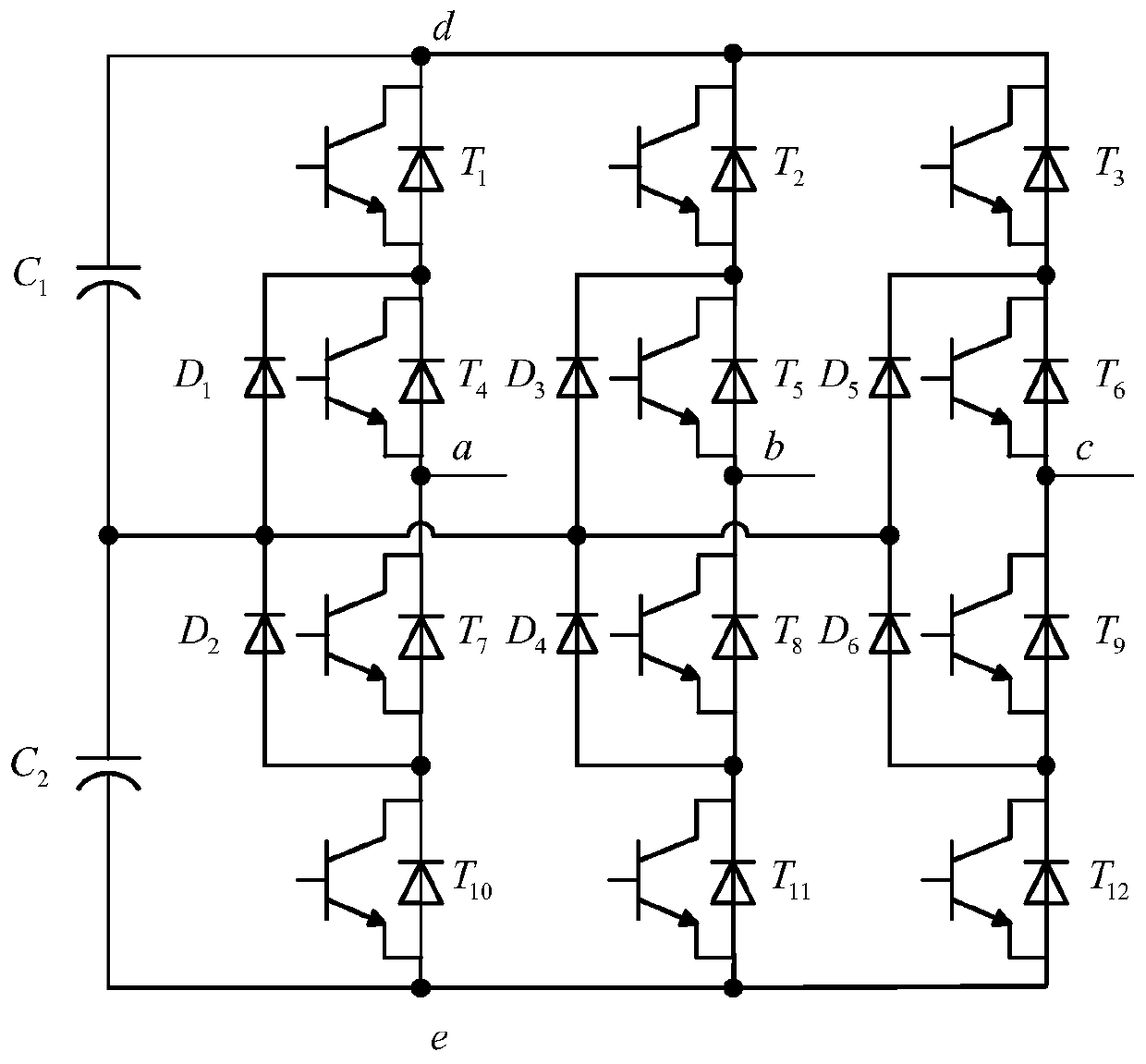

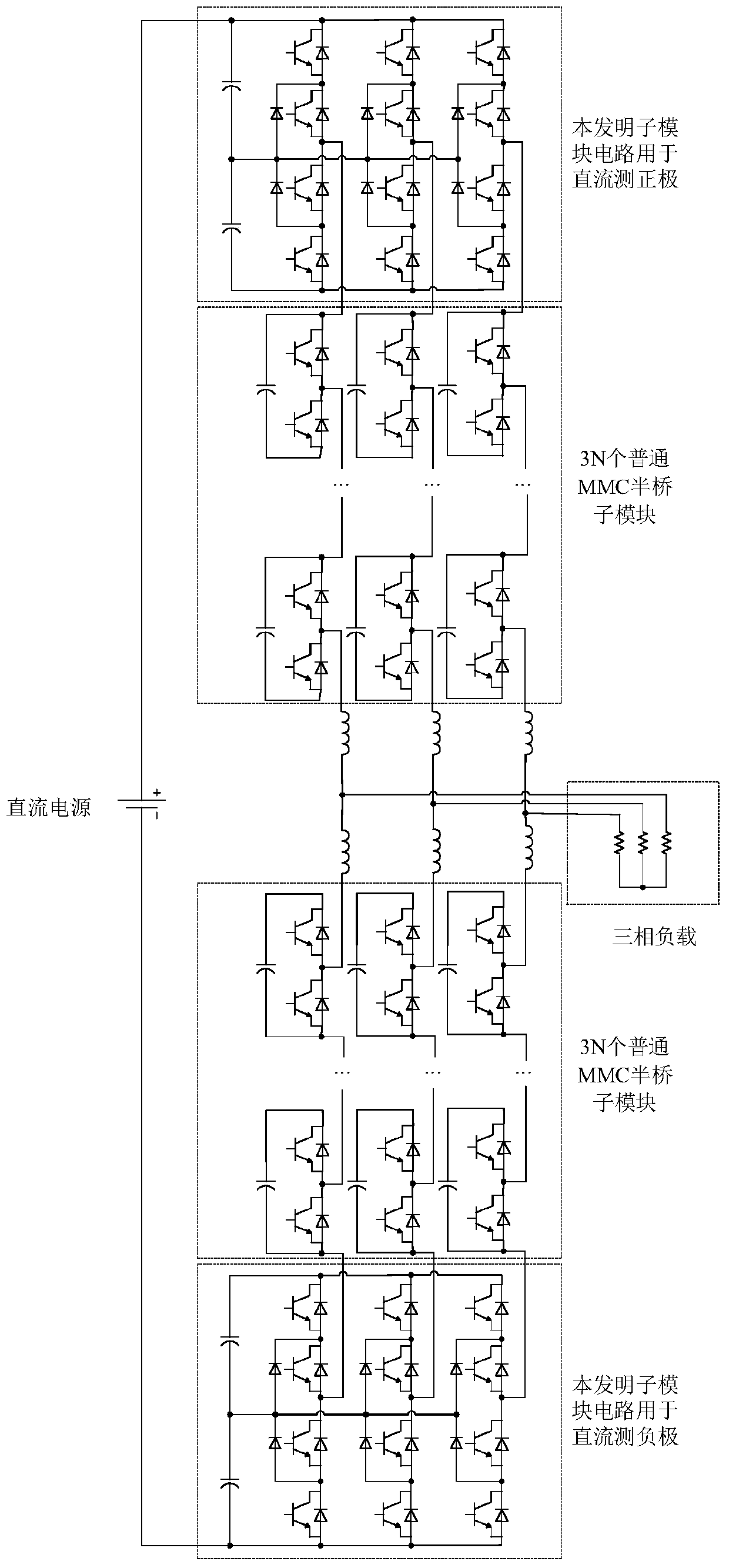

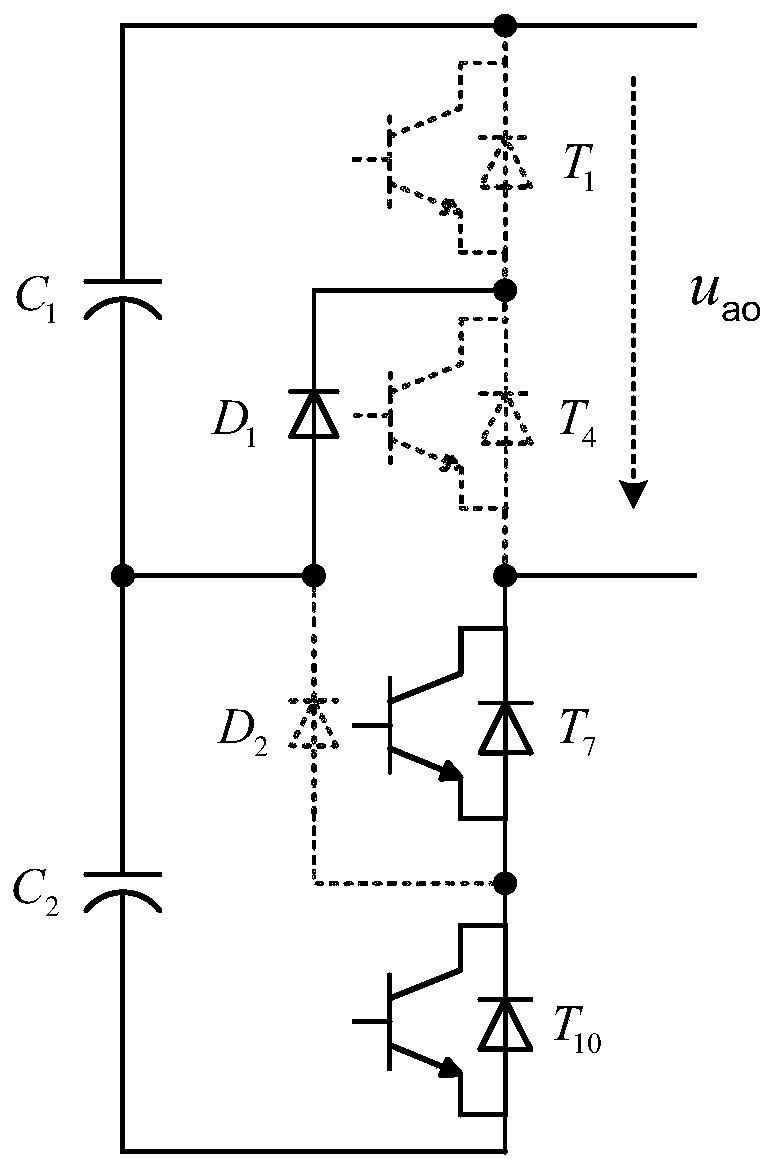

[0019] Such as figure 1 As shown, the sub-module circuit for the three-phase modular multilevel converter provided in this embodiment includes: 2 energy storage capacitors, respectively the first capacitor C 1 , the second capacitance C 2 , 6 power diodes, respectively the first diode D 1 , the second diode D 2 , the third diode D 3 , the fourth diode D 4 , the fifth diode D 5 , the sixth diode D 6 , 12 power switch tubes with reverse diodes, respectively the first switch tube T 1 , the second switching tube T 2 , the third switching tube T 3 , the fourth switching tube T 4 , the fifth switching tube T 5 , the sixth switching tube T 6 , the seventh switching tube T 7 , the eighth switching tube T 8 , the ninth switching tube T 9 , the tenth switching tube T 10 , the eleventh switching tube T 11 and the twelfth switching tube T 12 ; The first capacitance C 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com