Preparation method of instant wheat flour

A technology of wheat flour and low-gluten wheat flour, applied in the direction of food science, etc., to achieve the effects of avoiding peculiar smell, enhancing water absorption performance, and increasing porous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

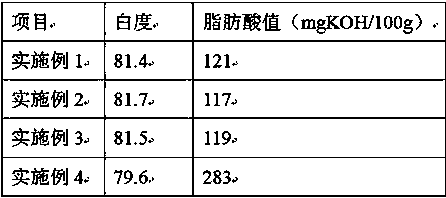

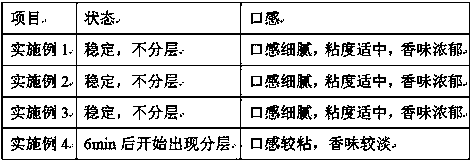

Examples

Embodiment 1

[0023] A preparation method for instant wheat flour, comprising the following steps:

[0024] Put the low-gluten wheat flour in an oven, adjust the oven temperature to 65°C, and dry until the moisture content is 0-2%, conduct preliminary gelatinization of wheat starch, increase the aroma of wheat starch, slowly remove residual moisture, and improve the quality of wheat starch. The brittleness of the particles is conducive to the further crushing of low-gluten wheat flour to obtain dried powder; then add purified water to the dried powder, mix well, make the water content 16-18%, and freeze at -21°C for 20 hours to make a preliminary paste After high and low temperature stress treatment after melting, it can enhance the water absorption performance and instant stability of starch, and inhibit the stratification of wheat flour after instant dissolution to obtain frozen powder; then take out the frozen powder and thaw it with microwave heating at a frequency of 500MHz to completel...

Embodiment 2

[0027] A preparation method for instant wheat flour, comprising the following steps:

[0028] Put the low-gluten wheat flour in an oven, adjust the oven temperature to 70°C, and dry until the water content is 0-2%, conduct preliminary gelatinization of wheat starch, increase the aroma of wheat starch, slowly remove residual moisture, and improve the quality of wheat starch. The brittleness of the particles is conducive to the further crushing of low-gluten wheat flour to obtain dried powder; then add purified water to the dried powder, mix well, make the water content 16~18%, and freeze at -22°C for 22 hours to make a preliminary paste After high and low temperature stress treatment after melting, the water absorption performance and instant stability of starch can be enhanced, and the stratification phenomenon after wheat flour instant dissolution can be suppressed to obtain frozen powder; then the frozen powder is taken out and microwave heating thaws at a frequency of 600MHz...

Embodiment 3

[0031] A preparation method for instant wheat flour, comprising the following steps:

[0032]Put the low-gluten wheat flour in an oven, adjust the oven temperature to 75°C, and dry until the moisture content is 0-2%, conduct preliminary gelatinization of wheat starch, increase the aroma of wheat starch, slowly remove residual moisture, and improve the quality of wheat starch. The brittleness of the particles is conducive to the further crushing of low-gluten wheat flour to obtain dried powder; then add purified water to the dried powder, mix well, make the water content 16~18%, put it in -23℃ for 24 hours, and make a preliminary paste After high and low temperature stress treatment after melting, the water absorption performance and instant stability of starch can be enhanced, and the stratification phenomenon after wheat flour instant dissolution can be inhibited to obtain frozen powder; then the frozen powder is taken out, and microwave heating and thawing is carried out at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com