Method for improving quality of whole-wheat biscuit

A biscuit and quality technology, applied in baked food, dough processing, pre-baked dough processing, etc., can solve the problems of prolonging baking time, increasing production energy consumption, increasing production cost, etc., achieving unique flavor, reducing fracture degree, improving The effect of muscle strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

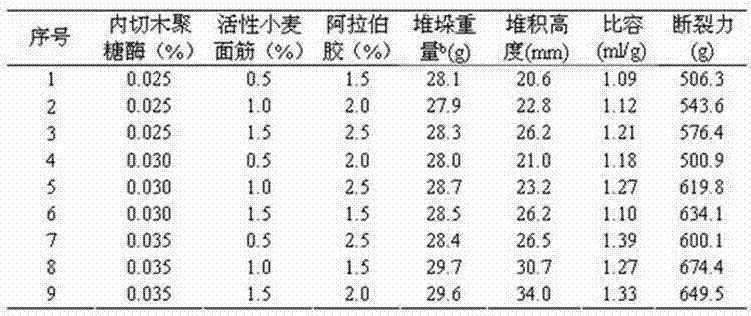

[0012] Example 1 Study on Quality Improvement of Whole Wheat Soda Crackers by Endoxylanase

[0013] Add different proportions (0%, 0.01%, 0.02%, 0.03%, 0.04%) of endoxylan to the soft white whole wheat flour (whole wheat flour) based on the weight of the soft white whole wheat flour in the graham soda cracker Enzymes, made into graham soda crackers.

[0014] The specific method of making whole wheat soda biscuits is as follows:

[0015] The amount of each raw material is as follows (baking ratio, w / w): soft white whole wheat flour with different proportions of endoxylanase added 100%, sourdough starter 4%, instant dry yeast 0.3%, mineral yeast food 0.03% , shortening 14%, salt 0.8%, baking soda 1.0%, distilled water 28%, after the preparation of the middle dough, the first fermentation, the preparation of the main dough, the second fermentation, and then shaping, calendering, splitting and beating Hole, baking, cooling, packaging and other processes to obtain finished produc...

Embodiment 2

[0026] Example 2 Study on the Quality Improvement of Active Wheat Gluten on Wholemeal Soda Crackers

[0027] Based on the weight of soft white whole wheat flour (whole wheat flour) in whole wheat soda biscuits, different weight percentages (0%, 1%, 2%, 3%, 4%) of active wheat gluten are added to the soft white whole wheat flour respectively, Make graham soda crackers. Raw material ratio and preparation method of whole wheat soda biscuits are the same as in Example 1.

[0028] The quality (stacking weight, stacking height, specific volume and Breaking force) evaluation, the evaluation results are shown in Table 3.

[0029] Table 3 Effects of different active wheat gluten additions on the quality of whole wheat soda crackers

[0030]

[0031] Note: a Indicates the weight on a dry basis, the values in the table are mean ± standard deviation, there is no significant difference between the values with the same letter (P<0.05), and each test is repeated at least three ti...

Embodiment 3

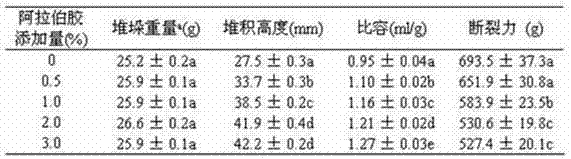

[0032] Example 3 Study on Quality Improvement of Gum Arabic on Whole Wheat Soda Crackers

[0033] Based on the weight of soft white whole wheat flour (whole wheat flour) in whole wheat soda biscuits, different weight percentages (0%, 0.5%, 1%, 2%, 3%) of gum arabic were added to the soft white whole wheat flour respectively to prepare Make graham soda crackers. Raw material ratio and preparation method of whole wheat soda biscuits are the same as in Example 1.

[0034] The quality (stacking weight, stacking height, specific volume and Breaking force) evaluation, the evaluation results are shown in Table 4.

[0035] Table 4 Effects of different amounts of gum arabic added on the quality of whole wheat soda crackers

[0036]

[0037] Note: a Indicates the weight on a dry basis, the values in the table are mean ± standard deviation, there is no significant difference between the values with the same letter (P<0.05), and each test is repeated at least three times; when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com