Tibet noodles and a preparing method thereof

A technology for Tibetan noodles and flour, applied in the field of Tibetan noodles and their preparation, can solve the problems of complicated process, difficult to shape noodles, inconvenient to carry, etc., and achieve the effects of rich wheat aroma, smooth strip shape, and easy portability and consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

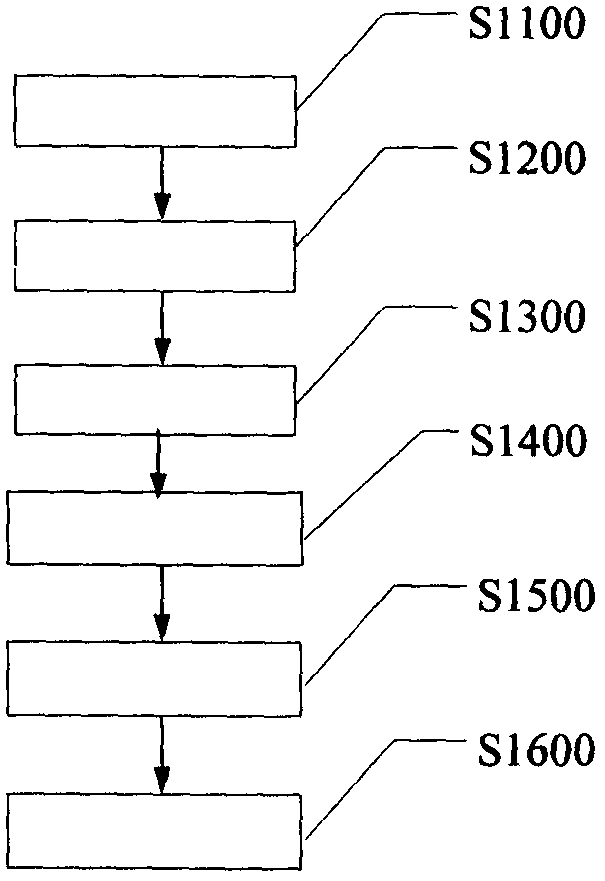

[0040] according to figure 1 As shown, the present invention also provides a kind of preparation method of Tibetan noodle, comprises the steps:

[0041] First enter S1100 to provide raw materials step: provide raw materials, the raw materials include 70-90 parts by weight of whole wheat Tibetan flour, 10-30 parts by weight of high-gluten flour, 0.5-2 parts by weight of corn flour, 0.5-2 parts by weight of table salt, stewing Fabric 0.1-1 weight part, baking soda 0.1-1 weight part.

[0042] Preferably, in the step of providing raw materials in S1100, the raw materials include 75-85 parts by weight of whole wheat Tibetan flour, 15-25 parts by weight of high-gluten flour, 0.8-1.5 parts by weight of gluten powder, 0.6-1.5 parts by weight of table salt, stewed noodle 0.2-0.8 parts by weight, 0.1-0.5 parts by weight of baking soda.

[0043] More preferably, in the step of providing raw materials in S1100, the raw materials include 80 parts by weight of whole-wheat Tibetan flour, 2...

Embodiment 1

[0058] Such as figure 1 As shown, the preparation method of the Tibetan noodle provided by the present invention comprises the following steps: first enter S1100 to provide the raw material step: provide the raw material, the raw material includes 70-90 parts by weight of whole wheat Tibetan flour, 10-30 parts by weight of high-gluten flour, corn 0.5-2 parts by weight of Yuanfen, 0.5-2 parts by weight of table salt, 0.1-1 part by weight of stewed fabric, and 0.1-1 part by weight of baking soda. Then enter the step of kneading dough in S1200: mixing the raw materials provided in step S1100 with water for kneading to form a dough, wherein the weight of the water is 25% of the total weight of the raw materials. Then enter the aging step of S1300: aging the dough provided in step S1200 with an aging machine. In this step, it is required that the temperature and water content of the dough cannot be too different from that after kneading, and the time is 10 minutes. Entering the s...

Embodiment 2

[0060] Such as figure 1 As shown, the preparation method of the Tibetan noodles provided by the present invention comprises the following steps: first enter S1100 to provide raw materials step: provide raw materials, the raw materials include 90 parts by weight of whole wheat Tibetan flour, 30 parts by weight of high-gluten flour, and 2 parts by weight of gluten powder 2 parts by weight, 2 parts by weight of salt, 1 part by weight of stewed fabric, and 1 part by weight of baking soda. Then enter the step of kneading dough in S1200: mix the raw materials provided in step S1100 with water for kneading to form a dough, wherein the weight of the water is 32% of the total weight of the raw materials. Then enter the aging step of S1300: aging the dough provided in step S1200 with an aging machine. In this step, it is required that the temperature and water content of the dough cannot be too different from that after kneading, and the time is 15 minutes. Entering the step of S1400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com