A treatment method for stabilizing/solidifying arsenic sulfide slag based on friedel salt

A treatment method, arsenic sulfide technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problem of leaching toxicity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take the arsenic sulfide slag produced by the sulfidation of foul acid hydrogen sulfide in a copper smelter. The slag has a moisture content of 75% and a leaching toxicity of 3181.5 mg / L. The analysis results of the main elements of the arsenic sulfide slag are shown in Table 1.

[0024] Table 1 Main elements of arsenic sulfide slag (%)

[0025]

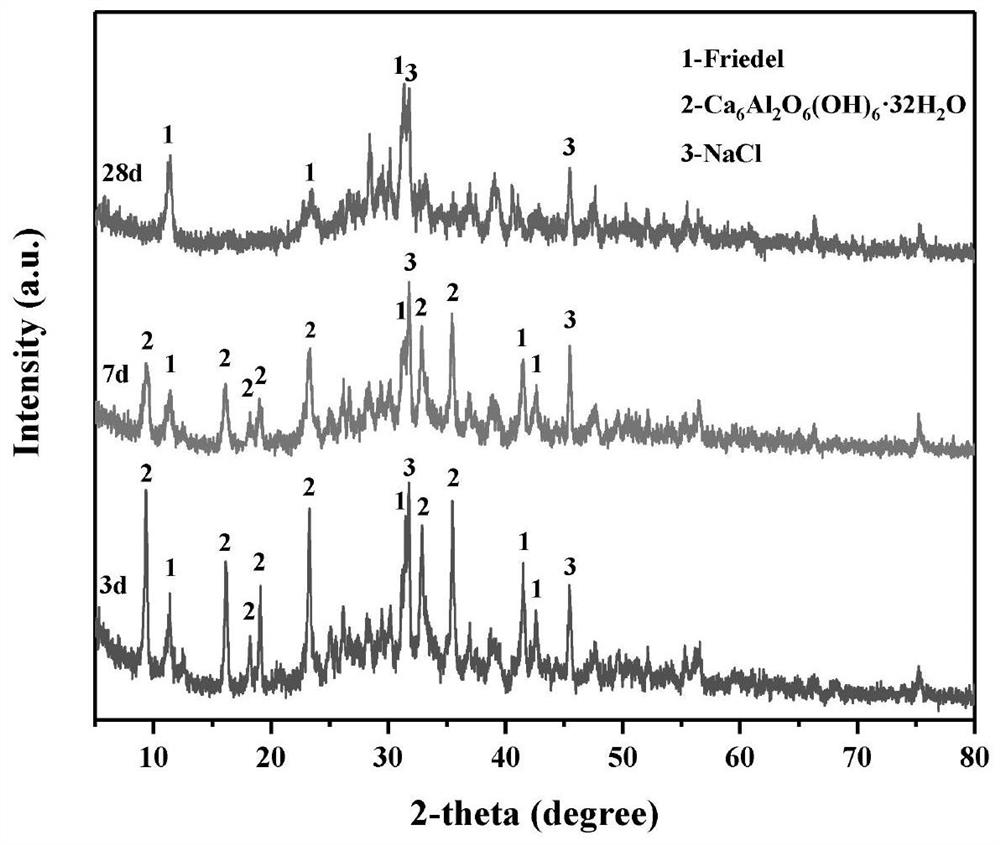

[0026] The arsenic sulfide slag was vacuum dried at 60°C to reduce the moisture content to less than 5%. Weigh 21.6g of waste incineration fly ash and 5.4g of aluminate cement according to the mass ratio of 8:2, and weigh 3g of dried arsenic sulfide slag at the same time, and mix the waste incineration fly ash, aluminate cement and arsenic sulfide slag evenly Standby (the total mass of the mixture is 30 g). Mix water glass with a modulus of 3.3 (the mass percentage of water content is 66%) and NaOH with a concentration of 96% to obtain an alkali activator with a modulus of 1.5, take 5ml of the alkali activator and 6.5ml o...

Embodiment 2

[0030]Take the arsenic sulfide slag produced by the sulfidation treatment of polluted acid sodium sulfide in a lead-zinc smelter. The slag has a moisture content of 52% and a leaching toxicity of 2903.1 mg / L. The analysis results of the main elements of the arsenic sulfide slag are shown in Table 3.

[0031] Table 3 Main elements of arsenic sulfide slag (%)

[0032]

[0033] The arsenic sulfide slag was vacuum dried at 60°C to reduce the moisture content to less than 5%. Weigh 22.95g of fly ash and 2.55g of aluminate cement according to the mass ratio of 9:1, and weigh 4.5g of arsenic sulfide slag at the same time, and mix the fly ash, aluminate cement, and arsenic sulfide slag evenly for use (the total mass of the mixture is 30g). Mix water glass with a modulus of 3.3 (the mass percentage of water content is 66%) and NaOH with a concentration of 96% to obtain an alkali activator with a modulus of 1.0. Take 5ml of the alkali activator and 6.5ml of distilled water, mix and ...

Embodiment 3

[0035] Take the arsenic sulfide slag produced by the sulfidation of foul acid hydrogen sulfide in a copper smelter. The slag has a moisture content of 70% and a leaching toxicity of 2832.4 mg / L. The analysis results of the main elements of the arsenic sulfide slag are shown in Table 4.

[0036] Table 4 Main elements of arsenic sulfide slag (%)

[0037]

[0038] The arsenic sulfide slag was vacuum dried at 60°C to reduce the moisture content to less than 5%. Weigh 21.6g of waste incineration fly ash and 5.4g of aluminate cement at a mass ratio of 8:2, and weigh 3g of arsenic sulfide slag at the same time, and mix the fly ash, aluminate cement, and arsenic sulfide slag evenly for use (the total mass of the mixture). 30g). Mix water glass with a modulus of 3.3 (water content mass percentage of 66%) and NaOH with a concentration of 96% to obtain an alkali activator with a modulus of 1.5. Take 5ml of the alkali activator and 6.5ml of distilled water, mix and shake well , slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com