On-site repairing device and method of converter supporting ring trunnions

A converter support ring and trunnion technology is applied in the field of converter support ring and trunnion field repairing devices, and can solve the problems that manual grinding cannot guarantee dimensional accuracy, high requirements on trunnion concentricity, and influence on normal production of equipment, etc., and achieves a simple structure. , good versatility, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific examples, but the scope of the present invention is not limited to the following examples.

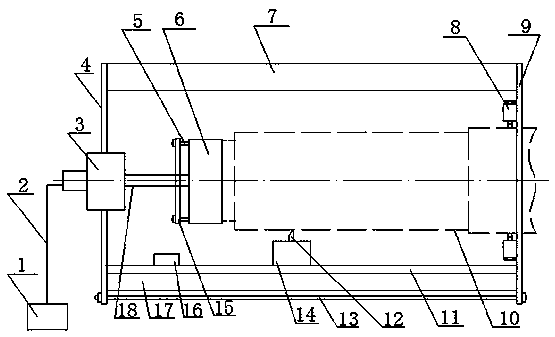

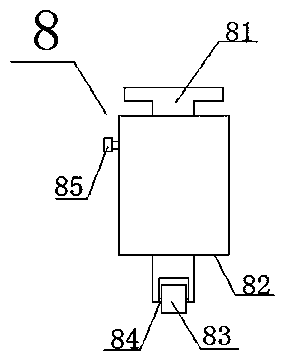

[0041] An online journal processing equipment, comprising: fixed shaft 17, concentric sleeve 6, driving end plate 4, driving device, controller 1, fixed shaft 17, driven end plate 9, connecting rod 13, centering device and processing device , the following combination figure 1 As shown, the above components are described in detail: the fixed shaft 17, one end is coaxially connected with one side of the concentric sleeve 6, and the other side of the concentric sleeve 6 can match the fixed journal 10; the active end plate 4 is arranged on the fixed shaft 17 The other end and the coaxial center with the fixed shaft 17 are driven by the driving device to rotate, and the driving device is controlled by the controller 1; the driven end disc 9 is parallel to the driving end disc 4 and coaxial with the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com