Multifunctional driver and new energy vehicle

A new energy vehicle and drive technology, applied in the direction of electric vehicles, control drive, vehicle components, etc., can solve the problems affecting the efficiency and reliability of the whole vehicle, the single function of functional modules, and the high price of the drive, so as to improve the ability of anti-electromagnetic interference , efficient heat dissipation, and convenient after-sales maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, a multifunctional driver.

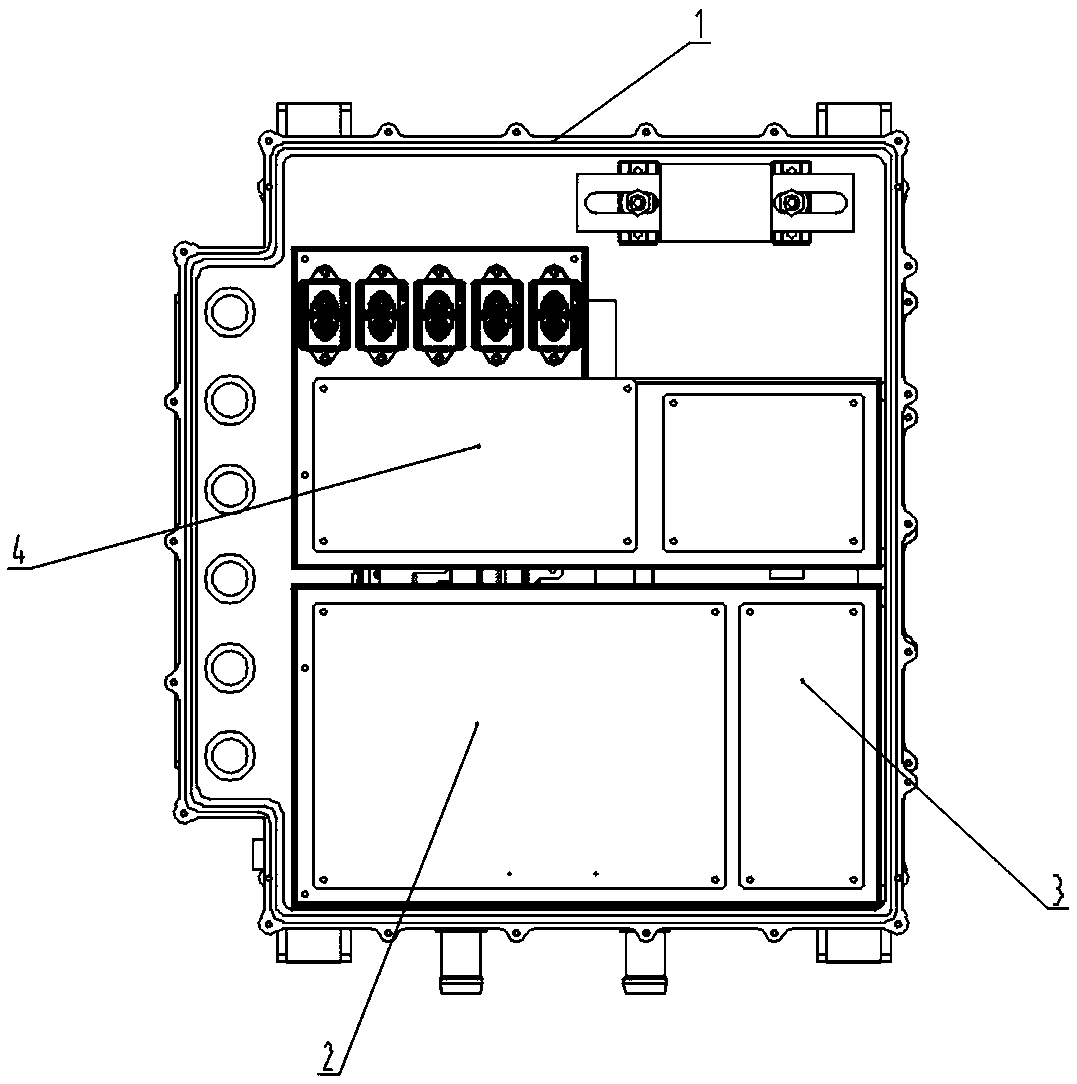

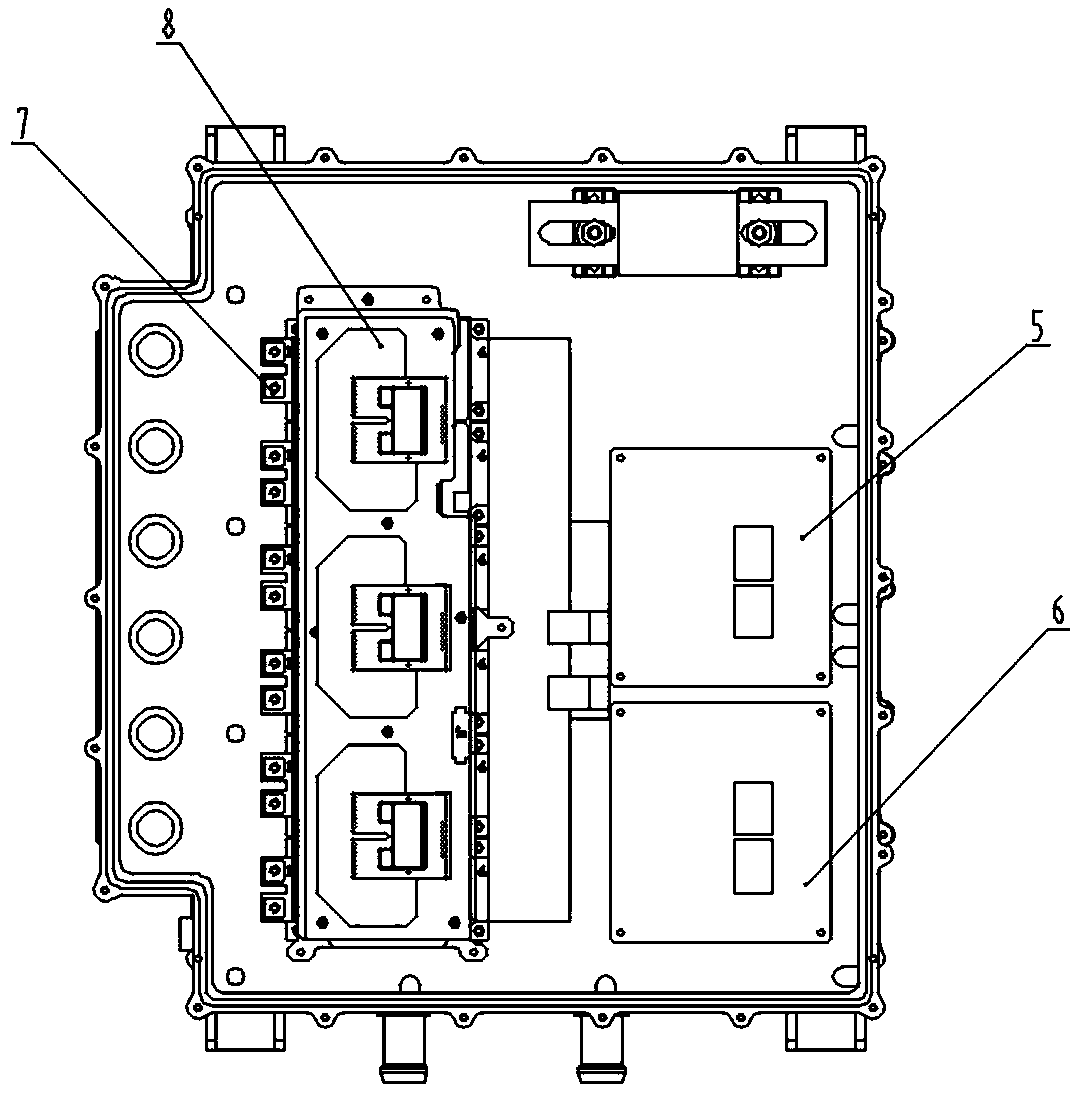

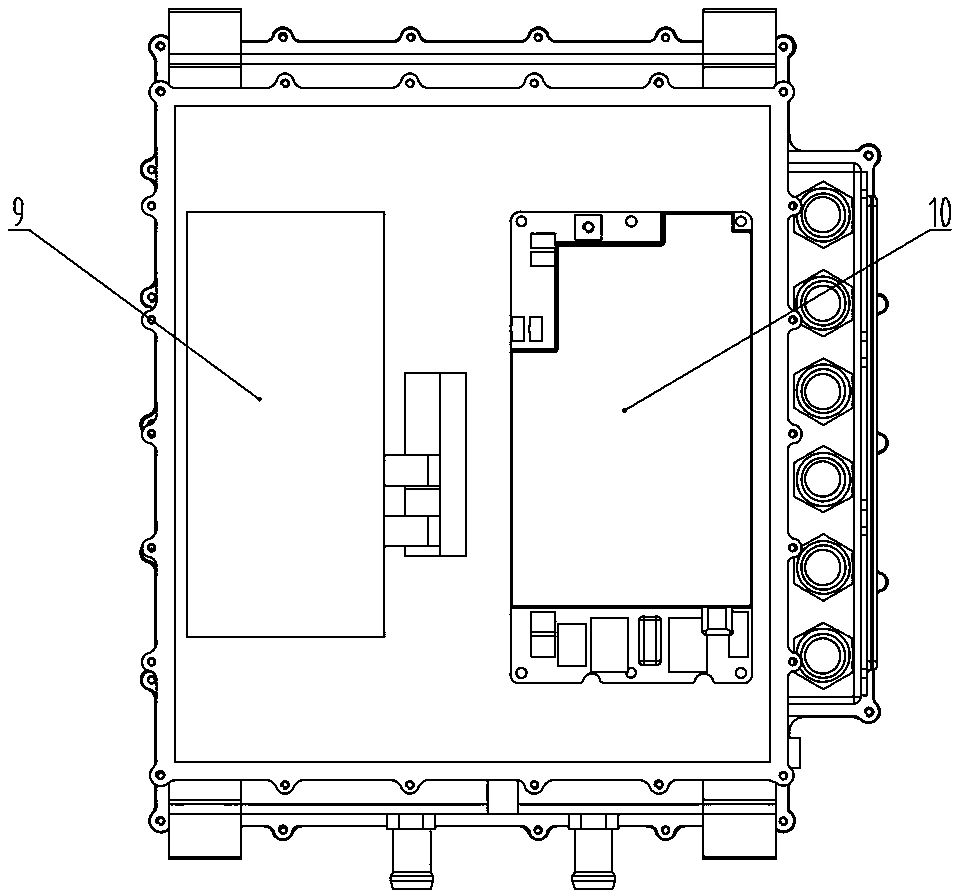

[0024] A multi-functional driver in this embodiment, the driver includes a driver housing 1, inside the driver housing 1 is provided with a plurality of functional modules, the functional modules are separately installed in the driver housing 1, and the driver housing 1 is provided with an upper The cavity and the lower cavity are provided with a heat dissipation plate between the upper cavity and the lower cavity. The heat dissipation plate includes a plurality of heat dissipation channels 11. The top layer of the upper cavity is installed with an integrated main control module 2. The integrated main control module 2 It includes motor control module, oil pump control module and air pump control module.

[0025] The motor control module, the oil pump control module and the air pump control module are all weak current control circuits, which are integrated in the integrated main control module 2, which is more conducive to the ra...

Embodiment 2

[0036] Embodiment 2, a kind of new energy vehicle.

[0037] This embodiment provides a new energy vehicle. The new energy vehicle includes the multifunctional driver described in Embodiment 1, the main drive motor, the oil pump motor, the air pump motor, the air pump, and the oil pump. The main drive motor and the main drive motor drive module 8 pass through the conductor Electrically connected, the oil pump motor and the oil pump motor drive module 5 are electrically connected through a conductor, the air pump motor and the air pump motor drive module 6 are electrically connected through a conductor, the air pump is connected to the air pump motor, and the oil pump is connected to the oil pump motor.

[0038] The control chip in the driver controls the operation of the main drive motor through the main drive motor drive module 8, controls the operation of the oil pump through the oil pump motor drive module 5, and controls the operation of the air pump through the air pump mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com