Sports shoe sole with high wear resistance and preparation process thereof

A technology of high wear resistance, sports shoes, applied in the direction of sole, footwear, application, etc., can solve the problems of heavy material, strong water absorption, easy water absorption, etc., to achieve the effect of overcoming defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

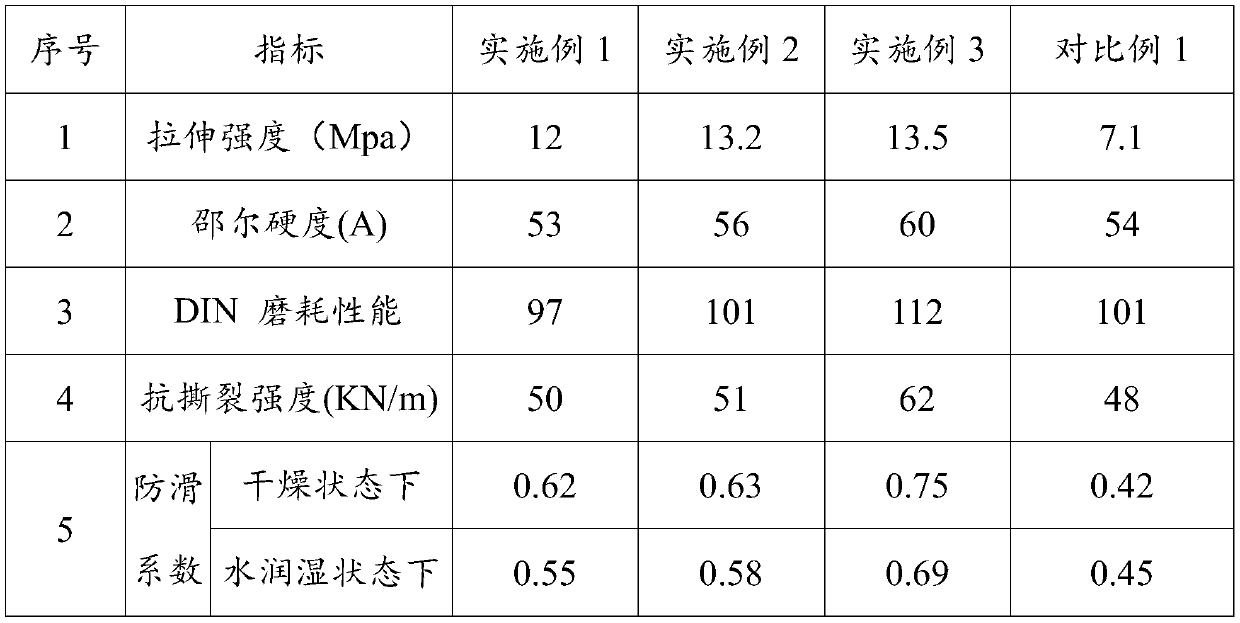

Embodiment 1

[0033] A sports shoe sole with high abrasion resistance is processed from the following components by weight:

[0034] 20 parts of PPSU, 5 parts of EVA, 5 parts of PETG, 3 parts of polyester polyol elastomer, 2 parts of polycarbonate, 6% of modified aramid fiber with a length of 20-30 μm, modified aramid microfiber with a length of 20-30 μm It is obtained by modifying poly-p-phenylene terephthalamide fiber. The processing steps are as follows: poly(p-phenylene terephthalamide) is dissolved with concentrated sulfuric acid and degassed; the processed hot material enters the grinding equipment together with a certain proportion of nano-scale additives, and is dispersed to the micron level after grinding; The final micron-scale hot material enters the coagulation bath to form, and then forms the finished product of modified aramid fiber through water washing, alkali washing, water washing and heat treatment. The grinding equipment adopts a ball mill, and the total mass of the mixt...

Embodiment 2

[0044] A sports shoe sole with high abrasion resistance is processed from the following components by weight:

[0045] 65 parts of PPSU, 15 parts of EVA, 18 parts of PETG, 5 parts of polyester polyol elastomer, 8 parts of polycarbonate, 10% of modified aramid fibers with a length of 20-30 μm, and modified aramid microfibers with a length of 20-30 μm are Poly(p-phenylene terephthalamide) fibers are obtained through modification treatment, and the processing steps of aramid microfibers with a length of 20-30 μm are as follows: Poly(p-phenylene terephthalamide) is dissolved with concentrated sulfuric acid and degassed The treated hot material enters the grinding equipment together with a certain proportion of nano-scale additives, and is dispersed to the micron level after grinding; the treated micron-sized hot material enters the coagulation bath to form, and then undergoes water washing, alkali washing, water washing and heat treatment to form a modified The finished product of...

Embodiment 3

[0055] A sports shoe sole with high abrasion resistance is processed from the following components by weight:

[0056] 50 parts of PPSU, 10 parts of EVA, 10 parts of PETG, 4 parts of polyester polyol elastomer, 5 parts of polycarbonate, 8% of modified aramid fibers with a length of 20-30 μm, modified aramid microfibers with a length of 20-30 μm are poly Terephthalamide fiber is obtained by modification. The processing steps are as follows: poly(p-phenylene terephthalamide) is dissolved with concentrated sulfuric acid and degassed; the processed hot material enters the grinding equipment together with a certain proportion of nano-scale additives, and is dispersed to the micron level after grinding; The final micron-scale hot material enters the coagulation bath to form, and then forms the finished product of modified aramid fiber through water washing, alkali washing, water washing and heat treatment. The grinding equipment adopts a ball mill, and the total mass of the mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com