Bow-shaped three-section type damping dislocation centrifugal washing device based on rotary drum oxygen bleaching

A centrifugal washing, three-stage technology, applied in the direction of centrifuges, biochemical equipment and methods, biochemical cleaning devices, etc., can solve the problems of affecting the shaft movement of the drum, tripping of the drum, and biological centrifugal vibration and crushing, etc., to achieve Improve the coverage effect and ensure the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

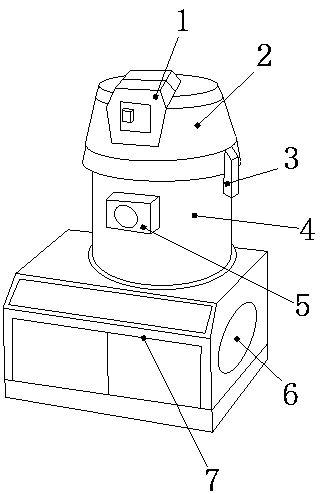

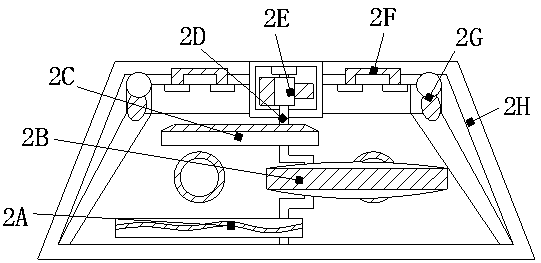

[0034] see Figure 1-Figure 7 , the present invention provides a bow-shaped three-stage damping dislocation centrifugal washing device based on drum oxygen bleaching. Cylinder 4, connecting column block 5, cooling plate 6, base case 7, said bow-shaft round table groove 2 is nested on the top of centrifugal oxygen drift cylinder 4 and the axes are collinear, said press-button top block 1 and bow The round table groove 2 of the word shaft is fastened together, the said pull bar block 3 is welded on the lower right corner of the round table groove 2 of the bow shaft, and the connecting column block 5 is closely attached to the front side of the centrifugal oxygen drift cylinder 4, and the heat dissipation There are two discs 6 and they are respectively nested on the left and right sides of the base case 7. The centrifugal oxygen drift cylinder 4 is inserted on the top of the base case 7 and is perpendicular to each other. Chassis 2A, arc pad spacer 2B, frame guide plate 2C, bow-...

Embodiment 2

[0041] see Figure 1-Figure 7 , the present invention provides a bow-shaped three-stage damping dislocation centrifugal washing device based on drum oxygen bleaching, the other aspects are the same as in Embodiment 1, the difference is that:

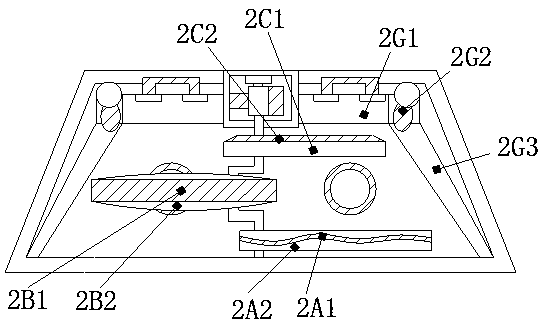

[0042] see image 3 , the balloon air tray frame 2G is composed of an air tray groove 2G1, a balloon ejector 2G2, and an air wall chute 2G3, and the air wall chute 2G3 is provided with two and respectively welded to the left and right lower corners of the air tray groove 2G1 , the balloon injector 2G2 is provided with two and respectively installed at the left and right ends of the gas disc groove 2G1, the gas disc groove 2G1 and the balloon injector 2G2 are on the same horizontal plane, and the balloon injector 2G2 is obliquely The air-supporting wall chute 2G3 forms the trapezoidal inclined surface and the wind wall effect around the wall.

[0043] see Figure 7 , the balloon injector 2G2 is composed of an I-shaped pressurized groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com