Vortex spinning fancy yarn

A technology of fancy yarn and vortex spinning, which is applied in the direction of yarn, textiles and papermaking, etc. It can solve the problems of unsatisfactory comprehensive performance, poor yarn elasticity, poor moisture absorption and moisture conduction performance, etc., to improve antistatic performance and elastic recovery Good sex, glossy and soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

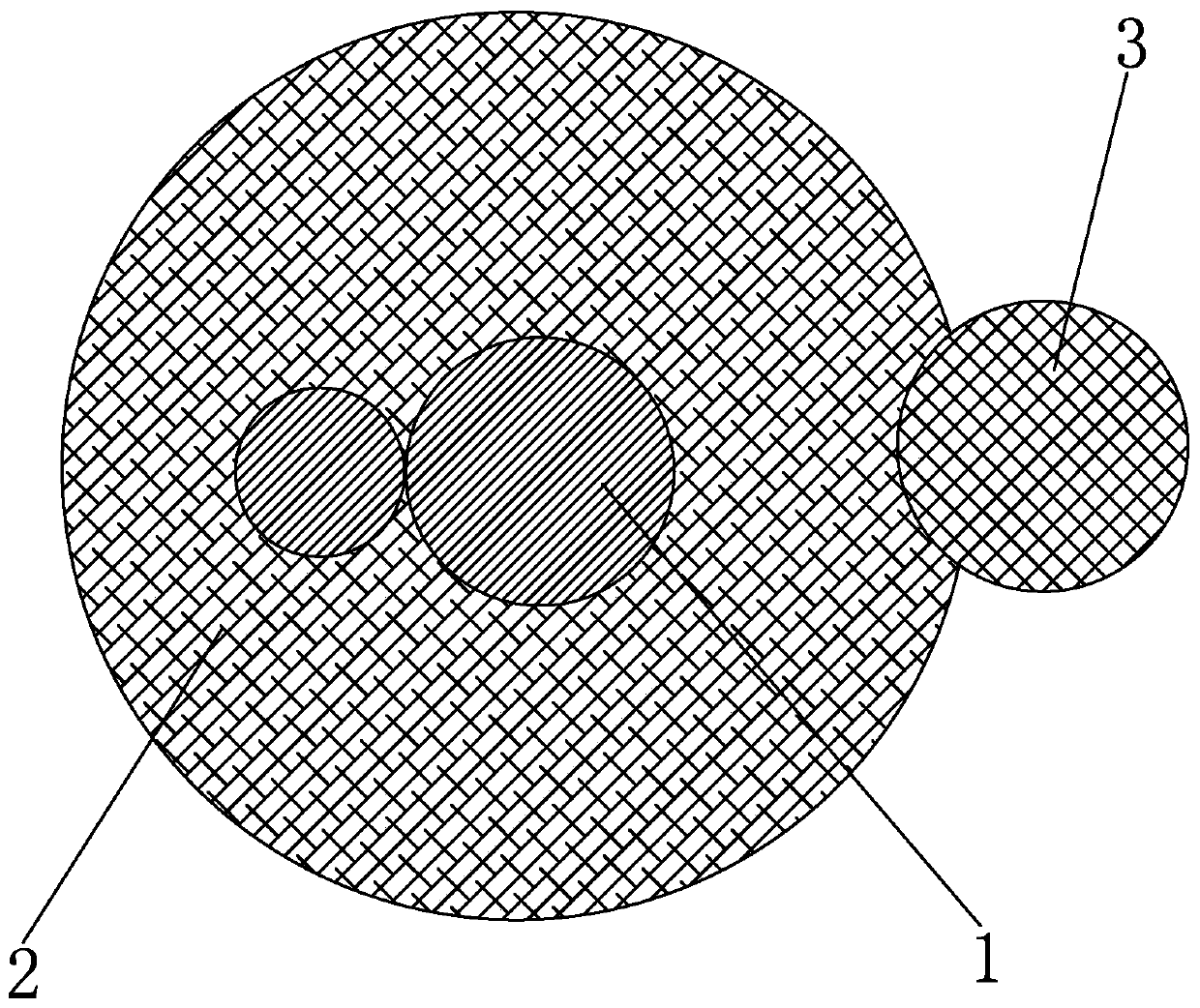

[0017] combine figure 1 , the invention discloses a vortex spinning fancy yarn, which includes a yarn body. The yarn body is a bouquet yarn structure. The yarn body includes a core yarn 1, a decoration yarn 2 and a consolidation yarn 3; the core yarn 1 is a composite ply yarn. Decorative yarn 2 is cashmere. Consolidated yarn 3 is fine denier tencel yarn. The composite strands are spandex filaments and carbon fiber filaments, and the spandex filaments are under a certain tension, and the carbon fiber filaments are spirally wound outside the spandex filaments. Preferably, the spandex filament is 3.8tex. The carbon fiber filament is 2.2tex. The core yarn 1 is under a certain tension, and the cashmere is spirally wrapped outside the core yarn 1; during the eddy current spinning process, the overfeed ratio of the core yarn and the decorative yarn is controlled at 1.5:1. Consolidated yarn 3 is helically wound outside core yarn 1 and decoration yarn 2 . Preferably, the consoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com