Beating-up box for air-jet loom

An air-jet loom and box technology, which is used in looms, textiles, textiles and papermaking, etc., can solve the problems of infeasible air-jet beating and weft insertion, unscientific structure, etc., and achieve long-stop weft insertion time and low vibration. , to achieve the effect of dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further description will be given below in conjunction with the embodiments and accompanying drawings.

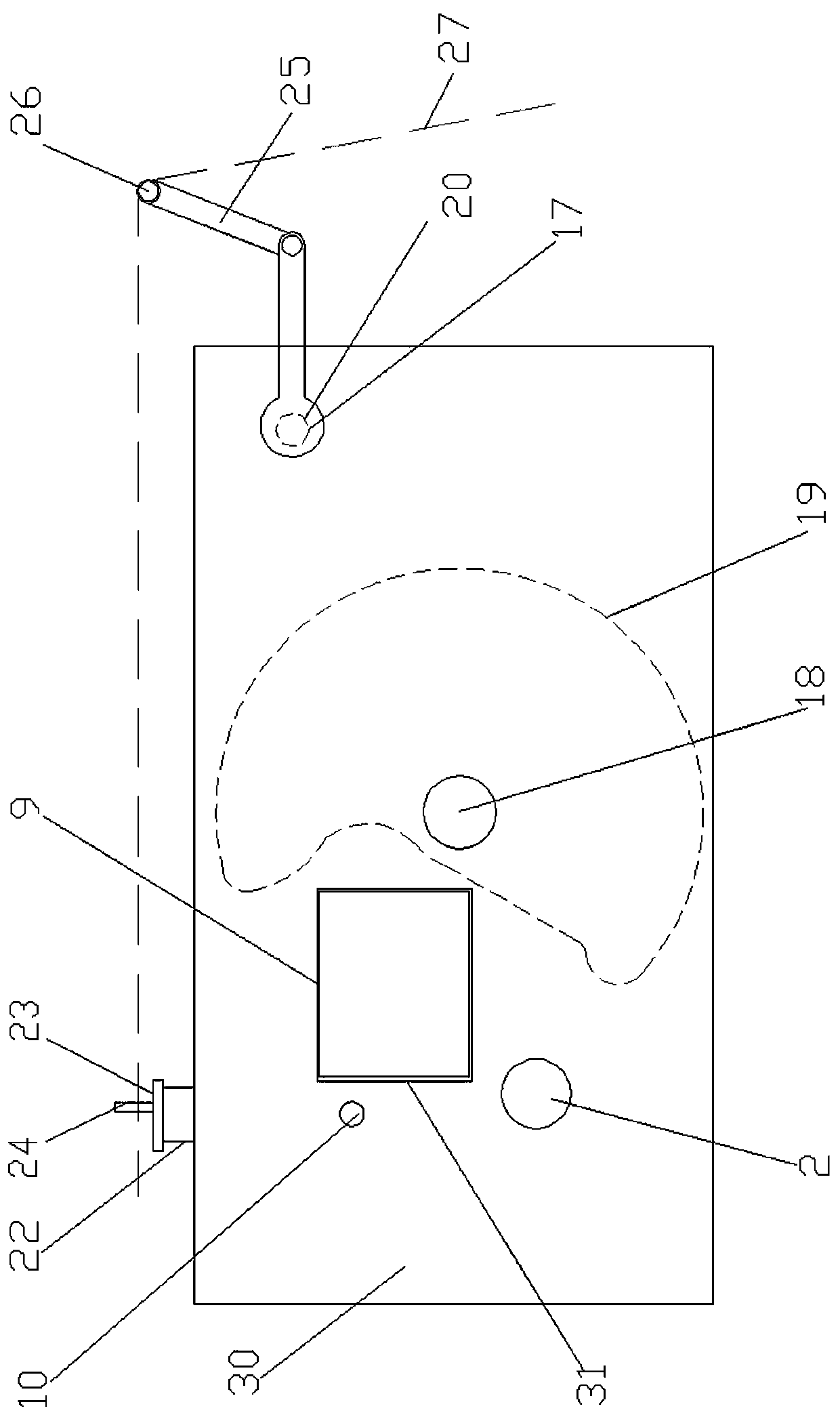

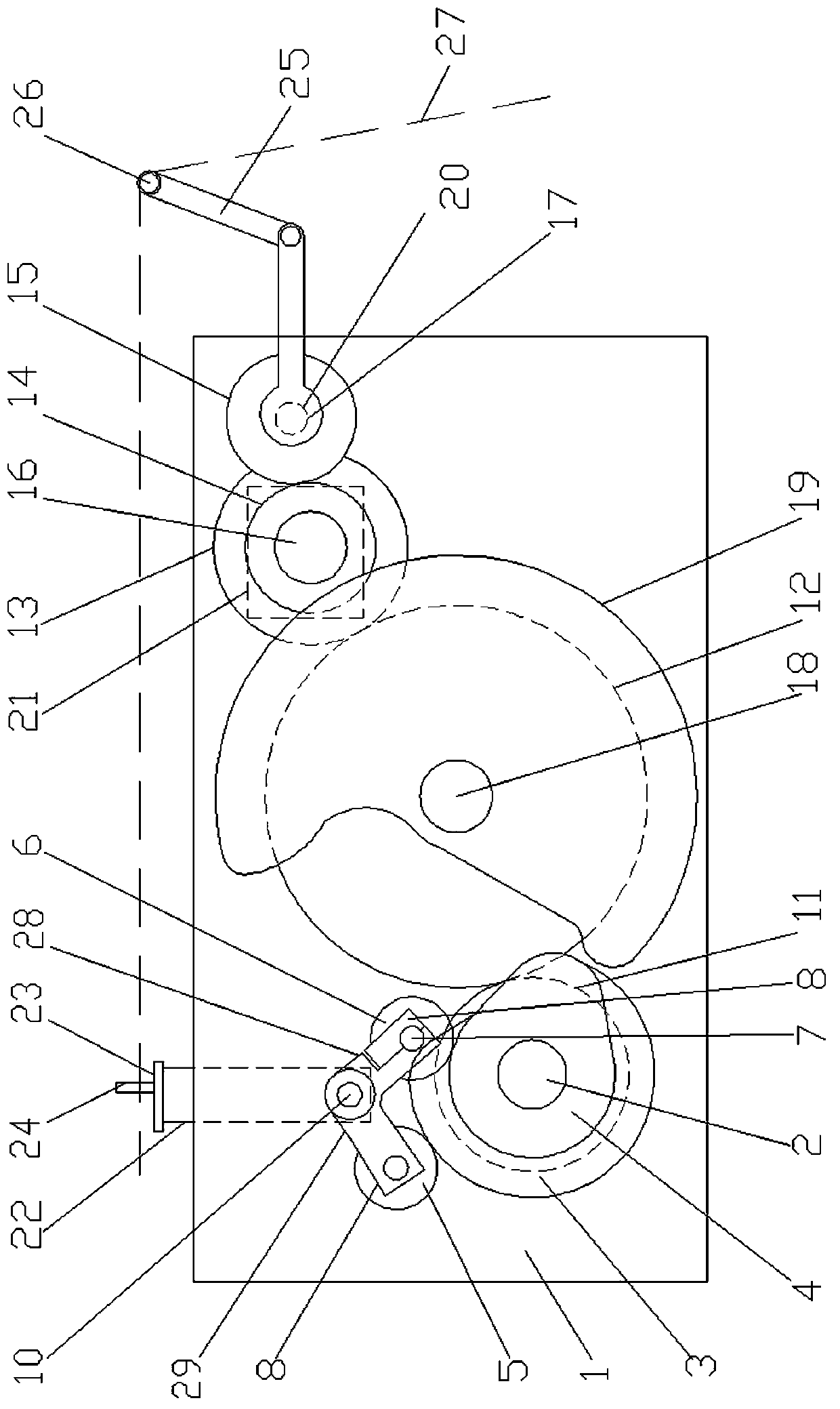

[0017] figure 1 , 2 Shown: A beating box of an air-jet loom includes a main box 1, a main shaft 2, an inner conjugate cam piece 3, an outer conjugate cam piece 4, an inner rotor 5, an outer rotor 6, and a rotor adjustable eccentric mandrel 7 , gland 8, pendulum shaft 10, primary driving gear 11, large bridge gear 12, primary driven gear 13, secondary driving gear 14, secondary driven gear 15, planetary hemming drive shaft 16, rear rod Swing eccentric cam drive shaft 17, large bridge gear shaft 18, small side plate 19 for supporting in the box, rear lever swing eccentric cam 20, planetary edge winch 21, sley foot 22, sley 23, beating reed 24, Rear lever 25, yarn guide shaft 26, driving force arm 28, driven force arm 29, large cover plate 30, outer sealing plate 31. The main box 1 is set on the side of the loom, the inner conjugate cam piece 3, the outer conjugate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com