Steel plate interface connecting structure and method for reinforced concrete beam and column

A technology of reinforced concrete beams and reinforced concrete, which is applied in the technical field of prefabricated structures, can solve the problems of large loss of tension friction prestress, difficulty in beam penetration, and irregular use of frame beams, and achieve simplified performance, improved shear resistance, and excellent performance. The effect of work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

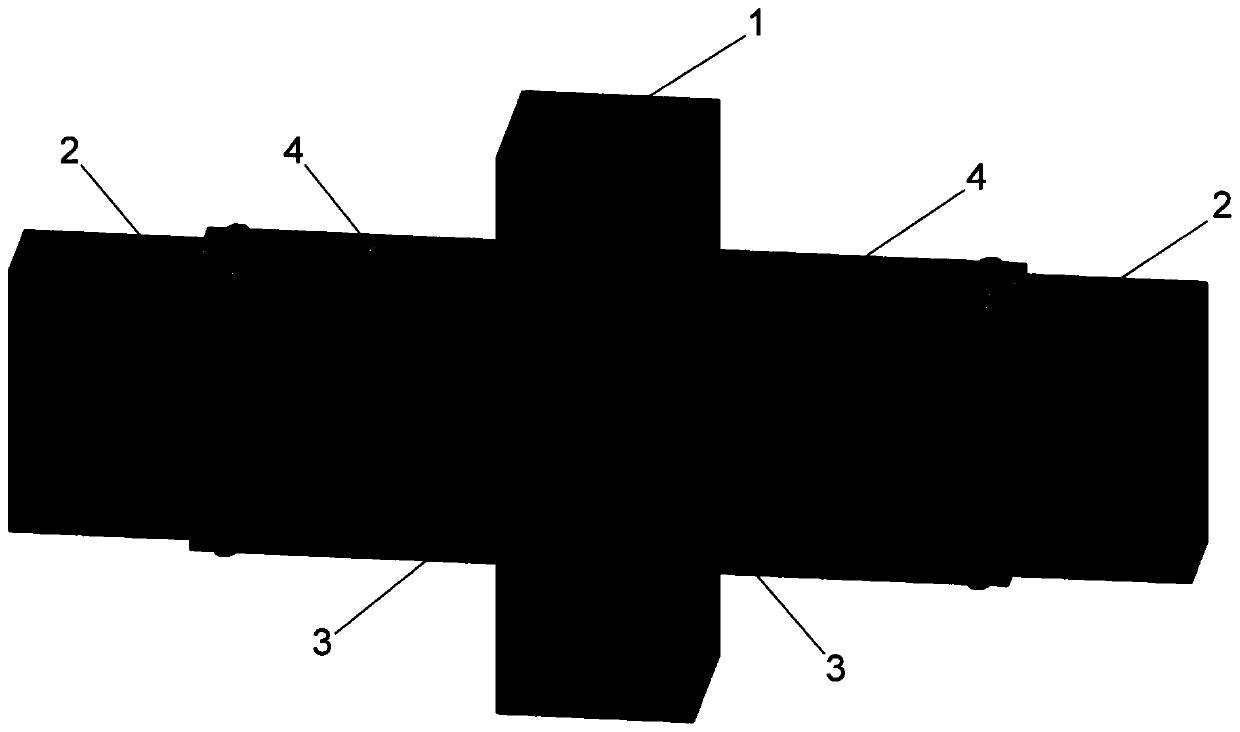

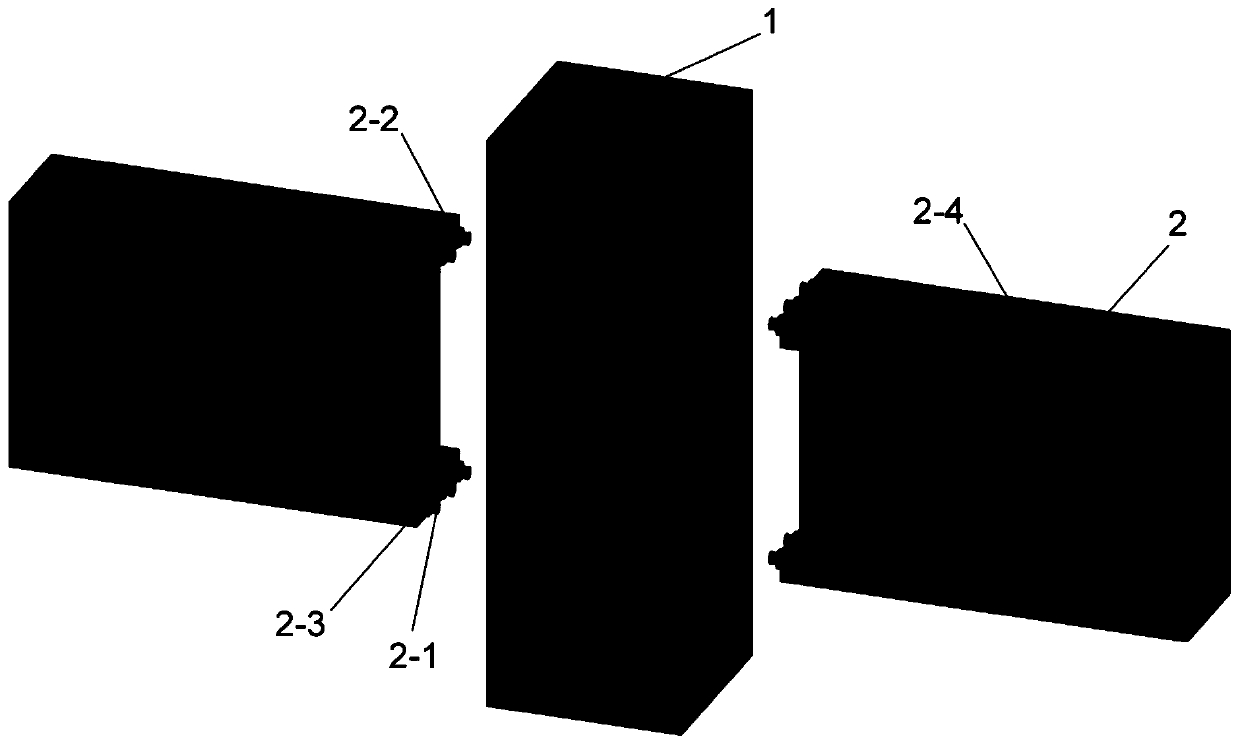

[0044] like Figure 1~4 Shown is a steel plate interface connection structure between reinforced concrete beams and columns, and the connection between prefabricated columns 1 and beams 2 is realized through auxiliary interface steel sleeves 3 and steel beam boots 4 .

[0045] The column 1 is a reinforced concrete prefabricated column with a rectangular cross-section, which is continuous on the side connected to the beam 2 without any reinforcement or hole.

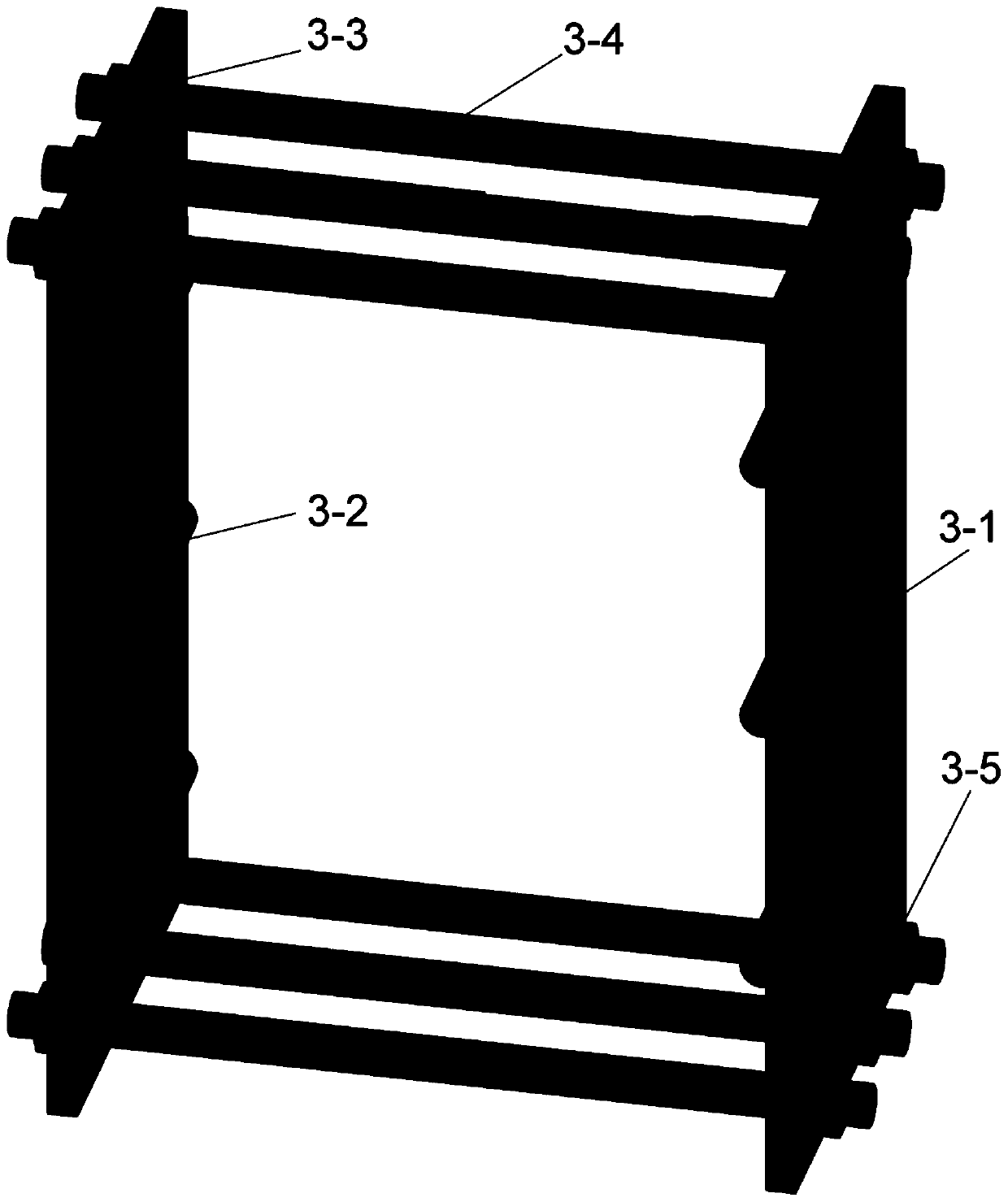

[0046] An interface steel sleeve 3 is provided at the connection part of the column 1 and the beam 2, and the interface steel sleeve 3 is composed of two interface steel plates 3-1, two sets of shear keys 3-2 and two sets of anchor bars 3-4.

[0047]The interface steel plate 3-1 is a rectangular steel plate whose size and position match the end face of the beam 2, and the inner side is attached to the column surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com