Drill float valve with automatic protection

An automatic protection and drilling tool technology, applied in earth-moving drilling, wellbore/well components, flushing wellbore, etc., can solve problems such as driving up drilling costs, difficult assembly, lax shut-down, etc., to reduce drilling risks and production. Cost, use and maintenance costs are low, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

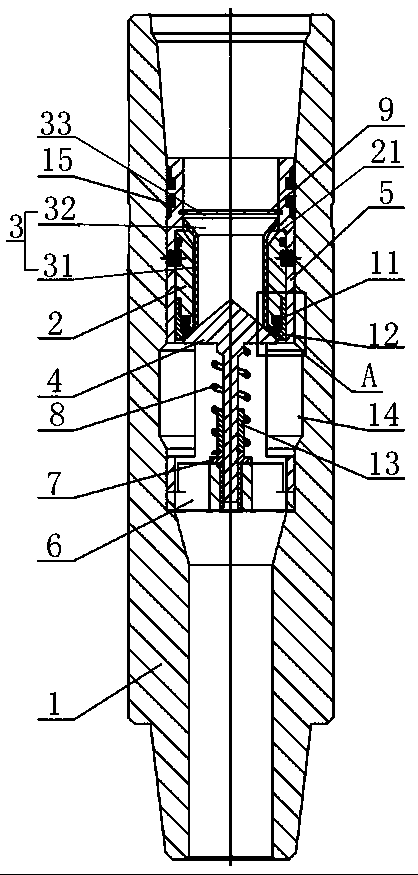

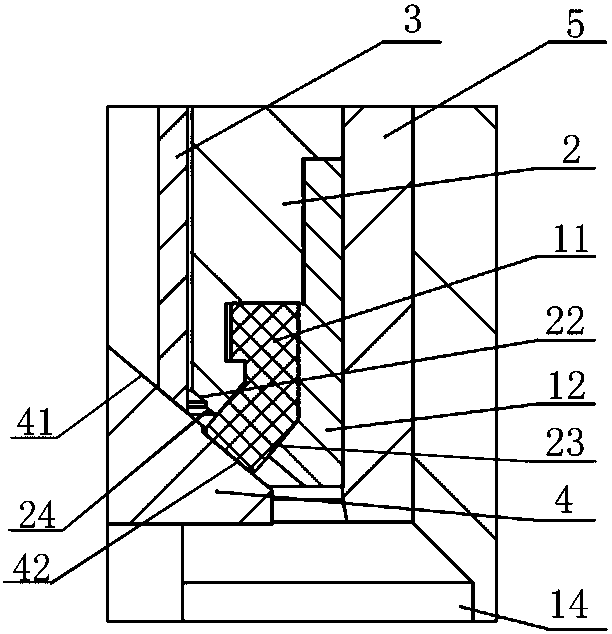

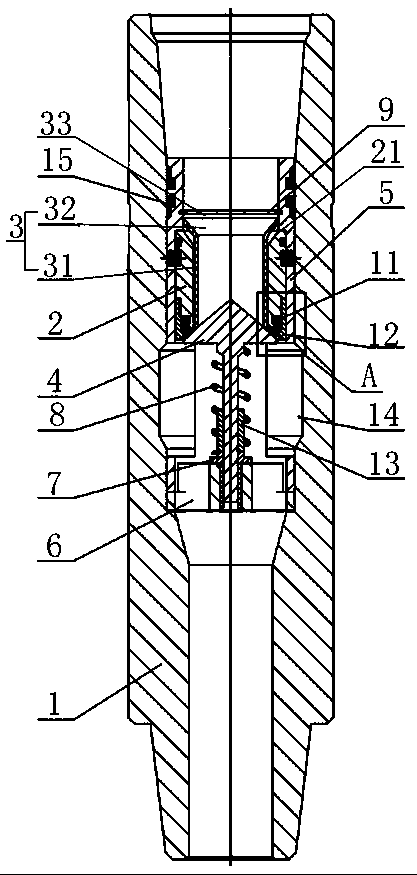

[0032] Reference figure 1 with figure 2 , A drilling tool float valve with automatic protection, comprising a valve body 1, a valve seat 2, a valve sleeve 5, a protection cylinder 3 and a mushroom head valve core 4. .

[0033] Among them, a valve sleeve 5 and a shunt seat 6 are respectively installed in the valve body 1 from top to bottom. The shunt seat 6 and the valve sleeve 5 are detachably connected together, and the shunt seat 6 sits on the inner hole step of the valve body 1. The sleeve 5 sits on the shunt seat 6, a guide spring seat 7 is also installed in the middle of the shunt seat 6, and a spring 8 is sleeved on the guide spring seat 7, through which the mushroom head valve core 4 can be reset. An elastic retaining ring 9 is fixed on the inner wall of the inner cavity of the valve sleeve 5 at the upper part, and the upward position of the protective cylinder 3 can be defined by the elastic retaining ring 9.

[0034] The valve seat 2 is arranged in the inner cavity of t...

Embodiment 2

[0038] Others are basically the same as Embodiment 1. The difference is that a limit sleeve 13 is provided on the upper end of the guide spring seat 7, and the limit sleeve 13 can be used to limit the lowermost position of the mushroom head valve core 4 to move down. Ensure the smooth passage of mud, on the other hand, protect the spring 8 from fatigue damage and prolong the service life.

[0039] In addition, a slow flow chamber 14 with a diameter larger than the diameter of the valve sleeve 5 is provided in the valve sleeve 5 below the valve seat 2. The valve sleeve 5 is provided with an opening that communicates with the slow flow chamber 14. The buffering effect prevents the hard impact of the mud.

[0040] An r-shaped sealing ring 15 sealed with the valve body 1 is provided on the valve sleeve 5.

[0041] The guide spring seat 7 is fixed in the middle of the shunt seat 6, and the middle of the guide spring seat 7 is provided with a guide cavity for the mushroom head valve core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com