A combined cycle high-efficiency coal-fired power generation system

A cycle system and combined cycle technology, applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve the problems of high temperature and high pressure material cost limitations, achieve the goal of reducing material cost, low material performance, and improving coal-to-electricity conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

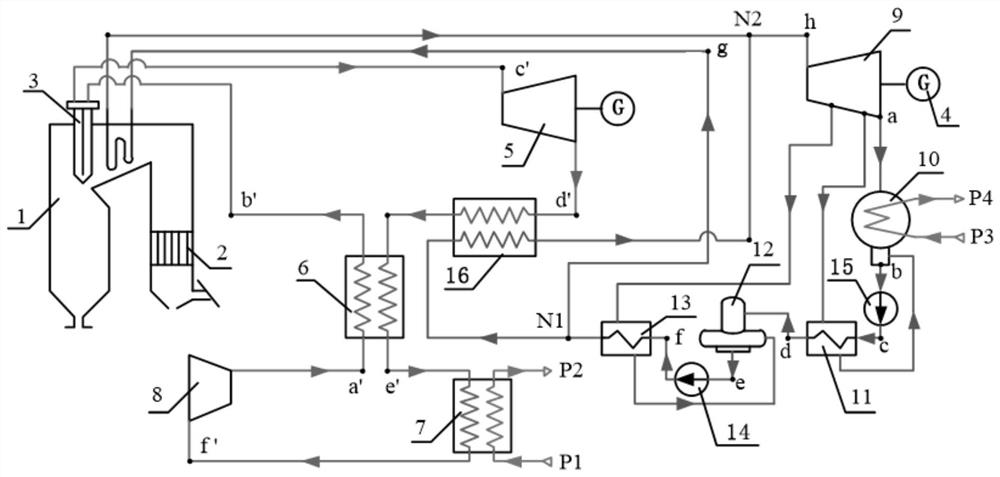

[0029] like figure 1 As shown, the present embodiment provides a combined cycle high-efficiency coal-fired power generation system, including: a coal-fired boiler 1, a supercritical CO 2 Circulation system and steam Rankine cycle system; supercritical CO 2 The circulation system and the steam Rankine cycle system are respectively connected to the coal-fired boiler 1;

[0030] Supercritical CO 2 The circulatory system includes: CO 2 Turbine 5, CO 2 Regenerator 6, CO 2 Cooler 7 and CO 2 booster 8; supercritical CO 2 circulatory system with CO 2 The fluid is a circulating working fluid, after CO 2 The CO after supercharging device 8 supercharging 2 fluid, in turn the CO 2 The regenerator 6 and the coal-fired boiler 1 absorb heat and heat up to the first temperature, and the CO after heat absorption and temperature rise 2 Fluid enters CO 2 Turbine 5 expands work, CO after work 2 Fluid passes through CO 2 Regenerator 6 and CO 2 Cooler 7 cooling, the cooled CO 2 Flui...

Embodiment 2

[0055] like figure 2 As shown, this embodiment provides a combined cycle high-efficiency coal-fired power generation system. On the basis of Embodiment 1, this embodiment also includes: a first CO 2 - steam heat exchanger 16;

[0056] Supercritical CO 2 CO in the circulatory system 2 CO after turbine 5 expands work 2 The fluid, after heat exchange with the steam Rankine cycle system in the first CO2-steam heat exchanger 16, enters the CO in sequence 2 Regenerator 6 and CO 2 Cooler 7 cooling;

[0057] In the steam Rankine cycle system, the pressurized water fluid after passing through the feed water pump 14 is divided into the first path and the second path, and the water fluid in the first path is in the first CO 2 -Steam heat exchanger 16 with supercritical CO 2 The circulation system performs heat exchange, and the water fluid of the second path absorbs heat and heats up in the coal-fired boiler 1, and the water fluid of the second path after heat absorption and temp...

Embodiment 3

[0063] like image 3 As shown, this embodiment provides a combined cycle high-efficiency coal-fired power generation system. In this embodiment, on the basis of Embodiment 1, the combined cycle high-efficiency coal-fired power generation system also includes: a second CO 2 - steam heat exchanger 17;

[0064] Supercritical CO 2 CO in the circulatory system 2 CO after turbine 5 expands work 2 The fluid, after heat exchange with the steam Rankine cycle system in the second CO2-steam heat exchanger 17, enters the CO in turn 2 Regenerator 6 and CO 2 Cooler 7 cooling;

[0065] In the steam Rankine cycle system, the pressurized water fluid after passing through the feed water pump 14 is divided into the third road and the fourth road, and the water fluid in the third road is in the second CO 2 -Steam heat exchanger 17 with supercritical CO 2 The circulation system performs heat exchange. The water fluid in the fourth path absorbs heat and heats up in the high-pressure heater 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com