Method for predicting service life of polystyrene material by using sun tracking condensation accelerated aging test

A technology of accelerated aging and sun tracking, which is applied in the fields of analyzing materials, measuring devices, design optimization/simulation, etc. It can solve problems such as low correlation of natural aging tests and spectral differences of artificial light sources, so as to reduce test workload and save test time , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

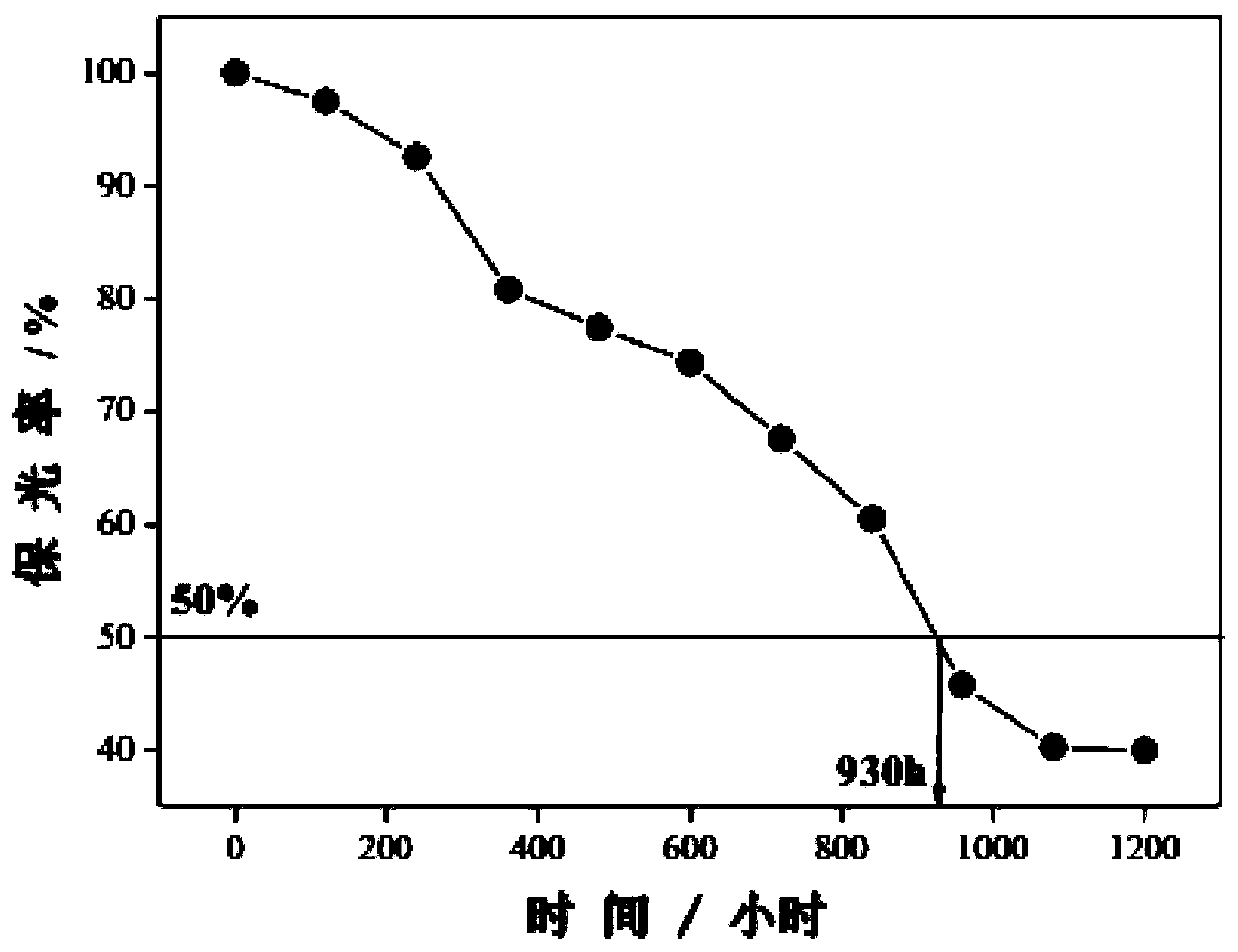

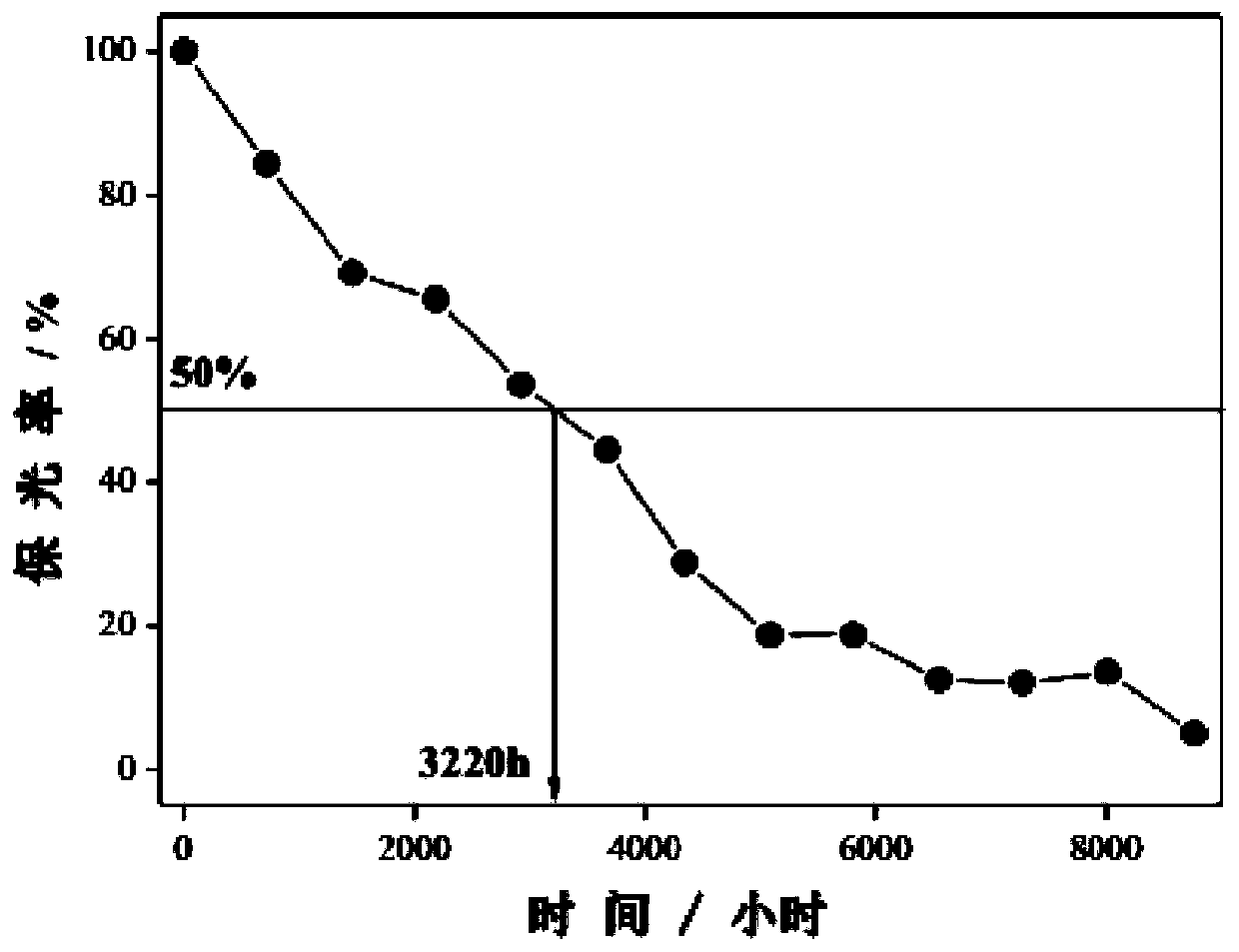

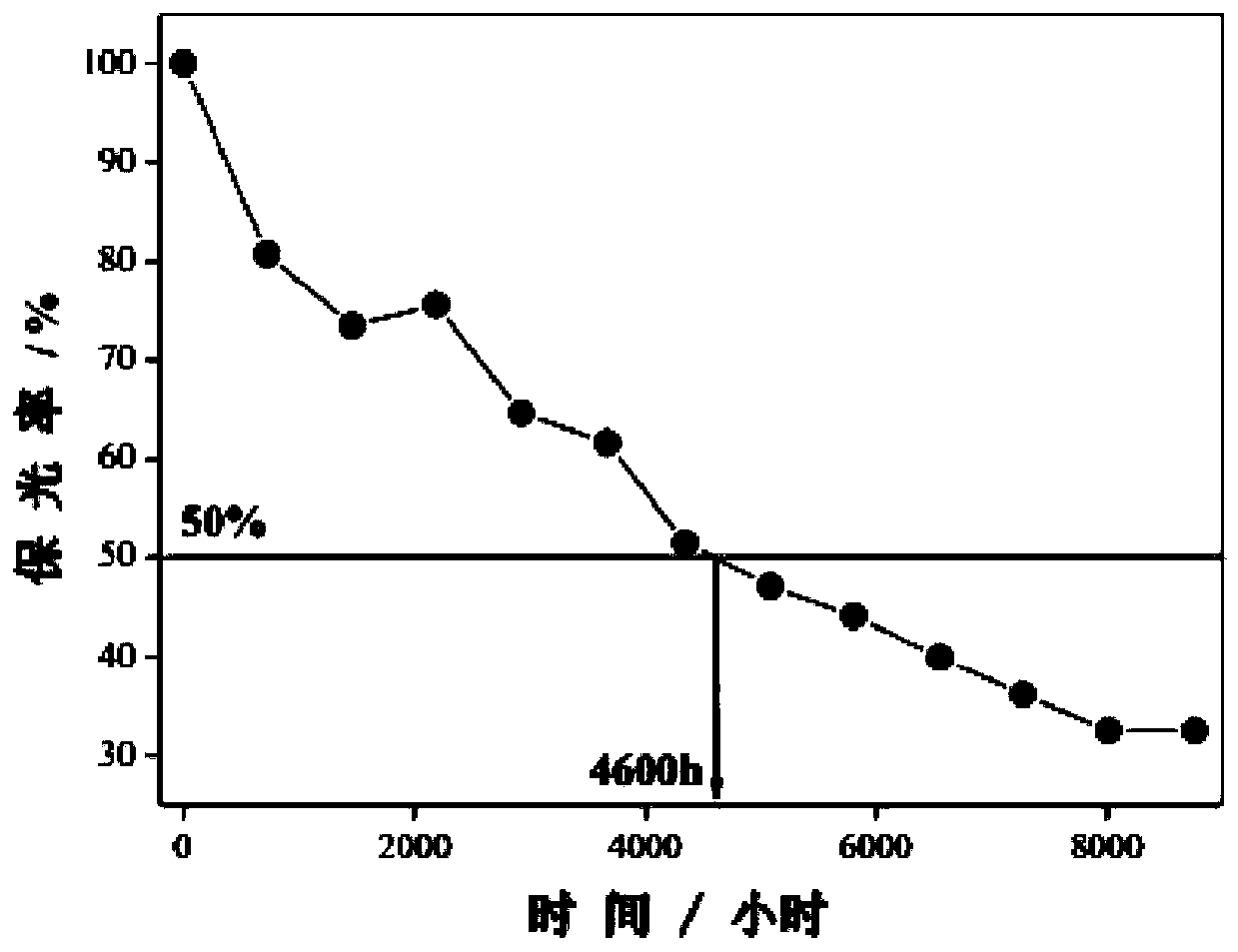

[0044] Applying the method of the present invention to predict the service life of PS materials in Phoenix, U.S.A. and Turpan, Xinjiang, the specific steps are as follows:

[0045] (1) To prepare PS samples, the PS samples are prepared by injection molding method with a size of 60mm×80mm×3mm; the gloss retention rate of the samples is tested before the test is carried out, and the results are tested for 3 samples, and the arithmetic mean of multiple tests is taken as the result value, recorded as the initial performance value of the sample;

[0046] (2) Carry out the sun-tracking concentrated light acceleration test in Phoenix, U.S. (as the selected area), record in the time of the whole year of 2018, the total solar ultraviolet radiation (Ir1 ), annual average temperature (T 1 ), annual mean relative humidity (RH 1 ), and get the following result:

[0047] I r1 =1271.03(MJ / m 2 )

[0048] T 1 =28.0(℃)

[0049] RH 1 =31.7(%)

[0050] (3) Statistically analyze the clima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com