Canned tuna production process and equipment thereof

A production process and technology of tuna, applied in the direction of freezing/cooling preservation of meat/fish, food science, etc., can solve the problems of poor thawing effect, achieve the effect of simple structure, fast and efficient thawing, and improve nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A process for making canned tuna, comprising the steps of:

[0039] 1. Raw material acceptance: Send the tuna that has passed the acceptance inspection to the refrigerator for frozen storage, and the refrigeration temperature is between -55°C and -60°C;

[0040] 2. Thawing: Take out the frozen tuna from the refrigerator for thawing, and take the temperature at the center of the tuna as 0°C as the end point of thawing;

[0041] (1), place the tuna after freezing in the vacuum chamber through a stainless steel mesh, and insert a thermocouple at the center of the tuna, then immerse the tuna in 3% ice-salt water; until the temperature of the center of the tuna reaches- 18°C;

[0042] (2), discharge the ice brine, and seal and vacuumize the vacuum chamber, then inject a certain proportion of O in the vacuum chamber 2 and CO 2 , and pressurize the interior of the vacuum chamber so that the internal pressure is 3×10 5 Pa, until the center temperature of the tuna reaches 0°...

Embodiment 2

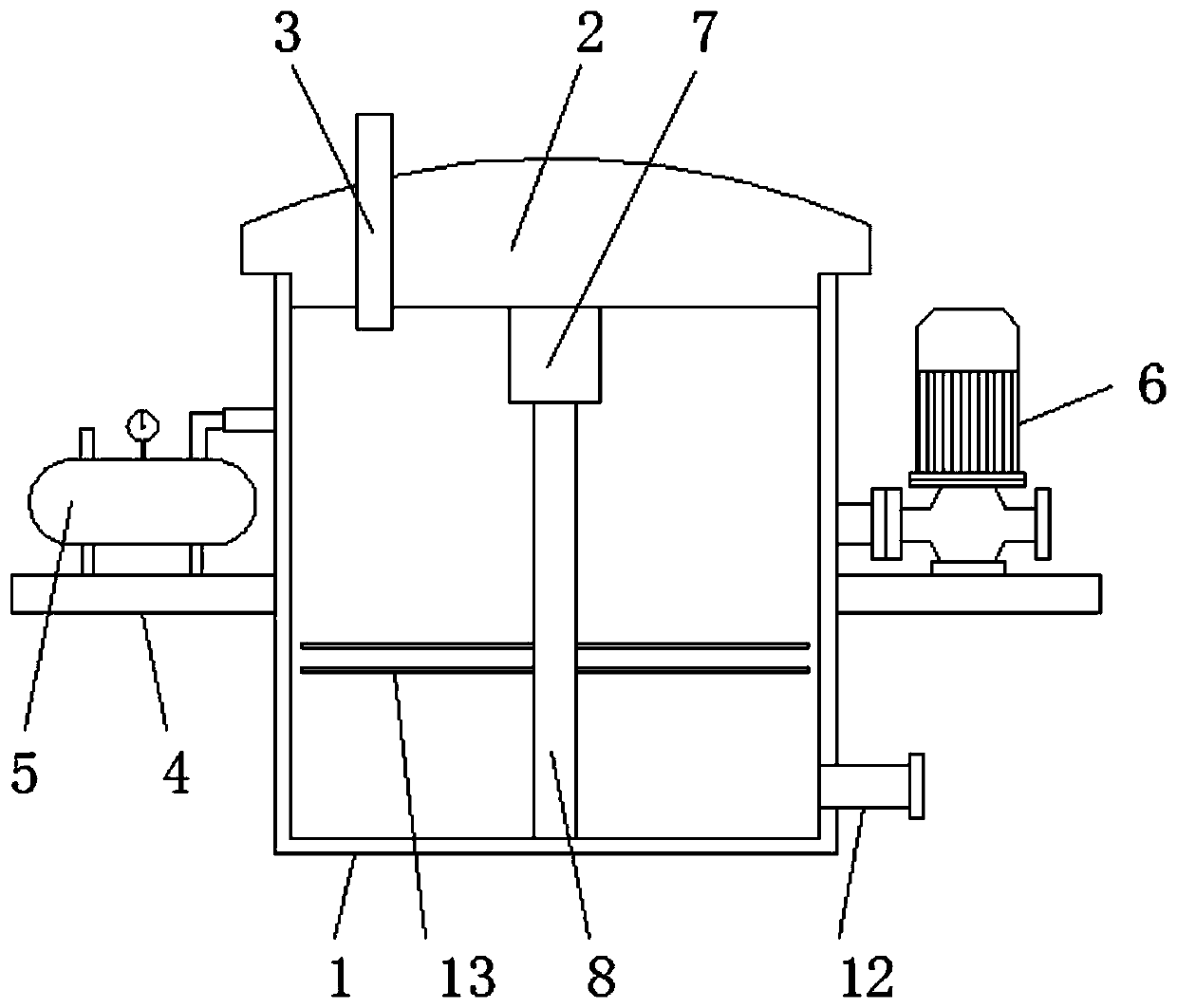

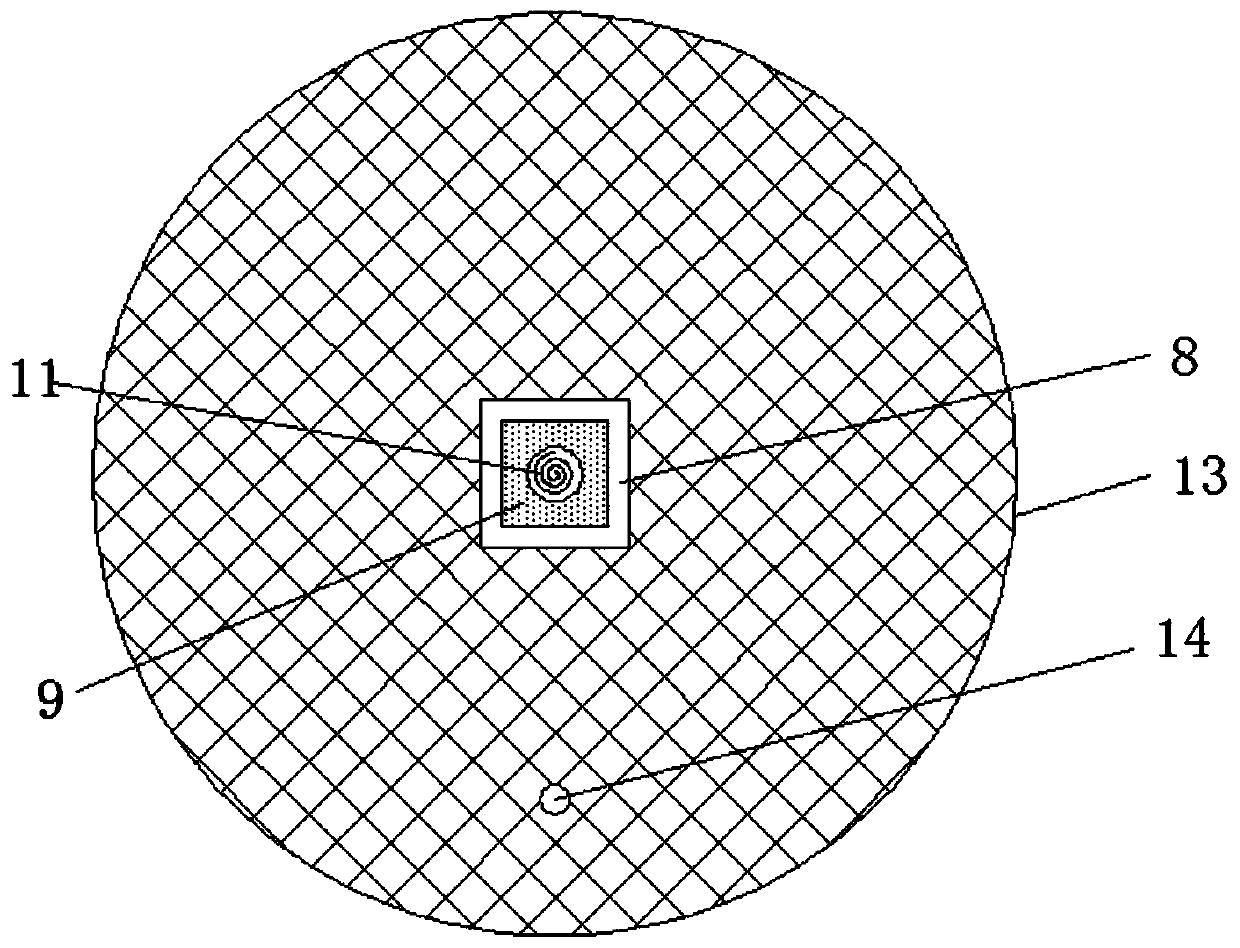

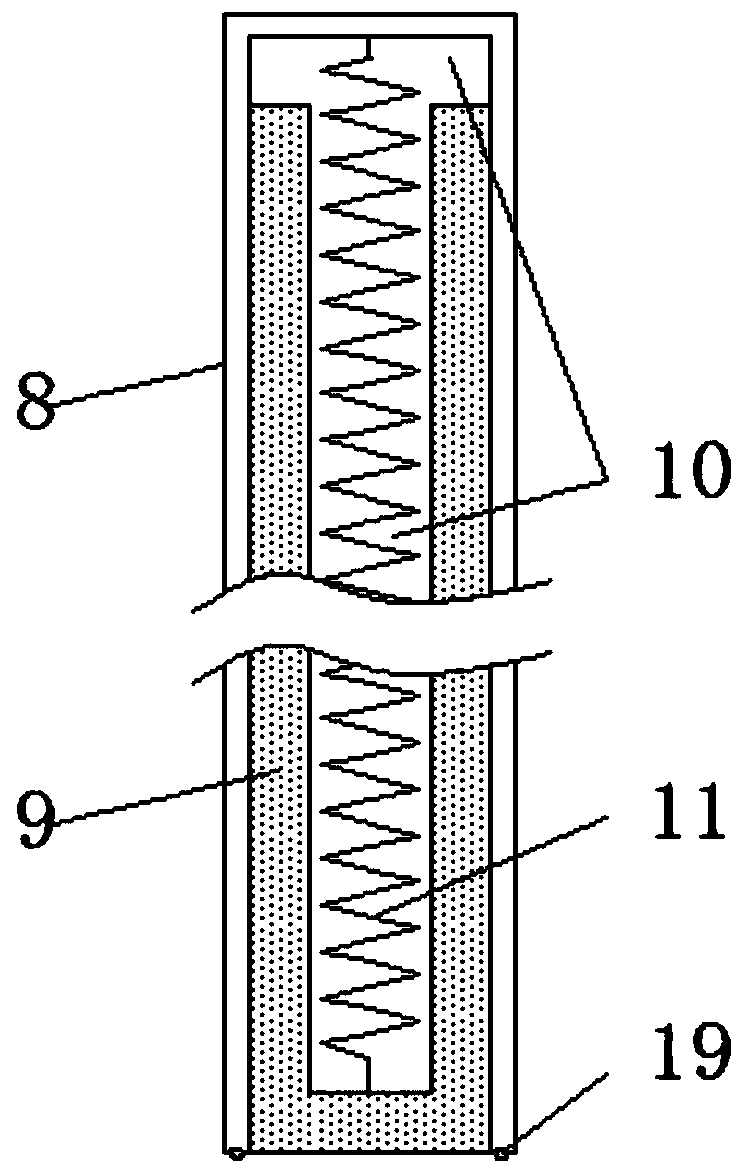

[0050] as attached Figure 1-5 As shown, a kind of canned tuna production equipment comprises a vacuum chamber 1, the top of the vacuum chamber 1 is provided with a top cover 2, and the outer wall of the vacuum chamber 1 is welded and connected with two mounting plates 4, and the vacuum chamber 1 is welded with the water inlet and outlet pipes 12 Connection, the front of the vacuum chamber 1 is provided with an opening groove 15, and the center of the inner wall of the bottom of the vacuum chamber 1 extends vertically upwards to form an internal fixing column 9, the top cover 2 is penetrated with an air intake pipe 3, and the connection between the air intake pipe 3 and the top cover 2 The center of the bottom surface of the top cover 2 extends vertically downward to form a vertical bar 7, and the two mounting plates 4 are respectively bolted with a vacuum pump 5 and a booster pump 6, and the vacuum pump 5 and the booster pump 6 are connected by welding. Both are sealed and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com