Beneficiation method for iron-titanium separation of titanium oxide-iron mixed ore

A technology of ferro-titanium oxide and mineral processing methods, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc., and can solve problems such as quality improvement and utilization technology blanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

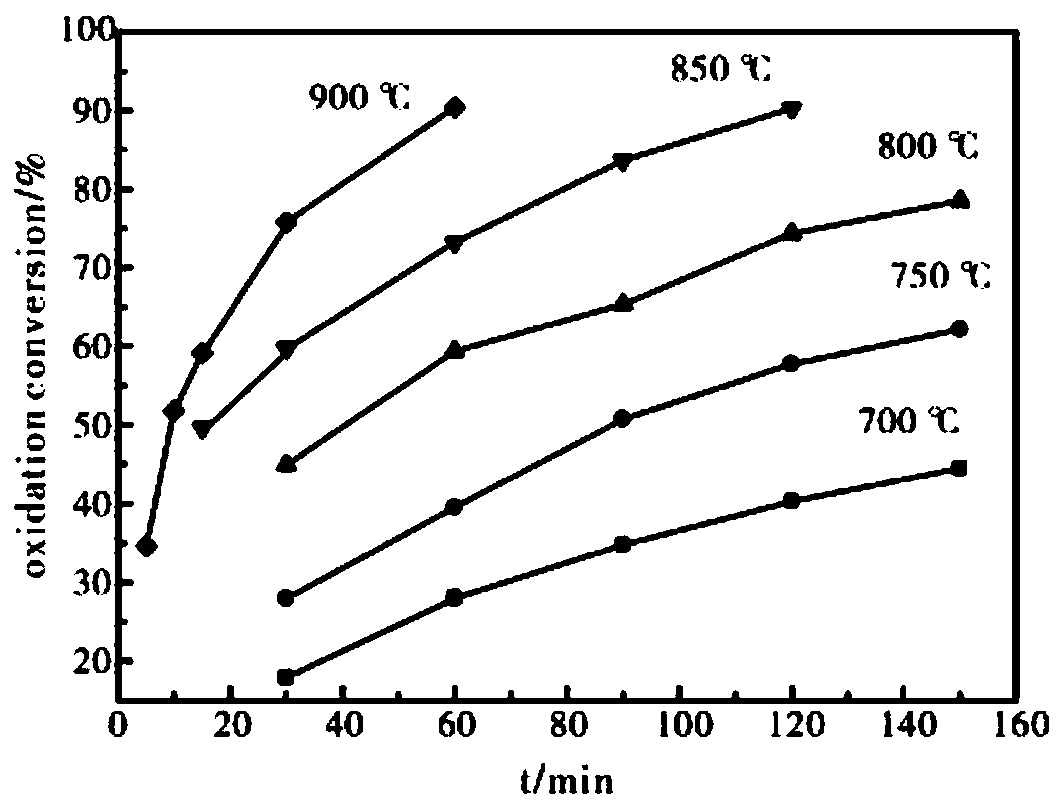

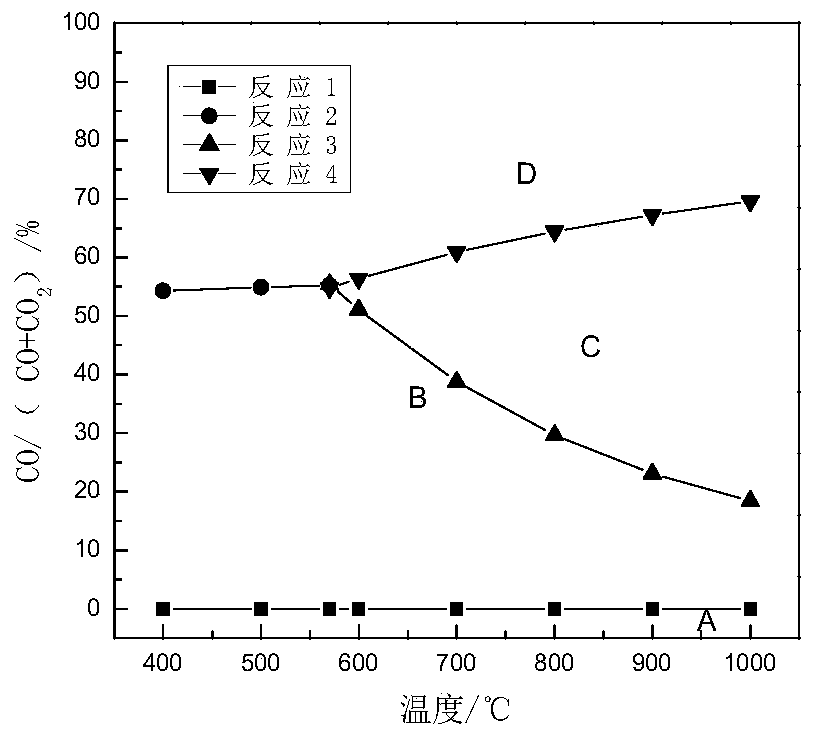

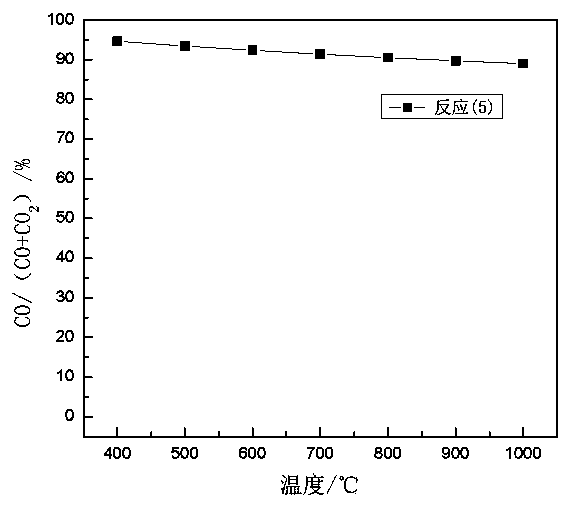

Embodiment 1

[0054] A mixture of ilmenite oxide and hematite, TiO 2 Content 35.34%, FeO content 18.60%, Fe 2 o 3 The content is 37.36%, and the total of the three is 91.30%. At a heating temperature of 750°C, a heating time of less than 30min, a fluidized roasting temperature of 600°C, a CO concentration of 50% to 70v / v%, a residence time of 60min, and direct water quenching, here The roasted products obtained under the conditions are subjected to wet weak magnetic separation with a magnetic field strength of 160kA / m. Obtained iron ore concentrate yield 38.99%, TiO 2 content 21.40%, TFe content 53.44%, TFe recovery rate 52.30%; titanium concentrate yield 61.01%, TiO 2 Content 44.84%, FeO content 31.53%, Fe 2 o 3 Content 9.49%, TiO 2 The recovery rate is 76.63%. (See the process Figure 4 )

Embodiment 2

[0056] The raw materials are the same as in Example 1, at a heating temperature of 750°C, a heating time of less than 30min, a fluidized roasting temperature of 650°C, CO+H 2 The concentration is 30%~50v / v%, the residence time is 30min, and the roasted product obtained under the condition of cooling under the protection of reducing gas is subjected to dry weak magnetic separation with a magnetic field strength of 80kA / m. / m dry strong magnetic separation. Obtained iron ore concentrate yield 35.13%, TiO 2 content 18.45%, TFe content 55.98%, TFe recovery rate 48.34%; titanium concentrate yield 58.14%, TiO 2 Content 46.30%, FeO content 33.00%, Fe 2 o 3 Content 8.69%, TiO 2 Recovery rate 77.12%; tailings yield 6.73%, TiO 2 The content is 39.59%, and the TFe content is 29.22%. (See the process Figure 5 )

Embodiment 3

[0058] A mixture of ilmenite oxide and hematite, TiO 2 content 43.04%, FeO content 28.91%, Fe 2 o 3 The content is 21.99%, the total of the three is 93.94%. At a heating temperature of 600°C, a heating time of less than 30min, a fluidized roasting temperature of 550°C, a CO concentration of 70% to 90v / v%, and a residence time of 120min, it is cooled under nitrogen protection. The roasted products obtained under the conditions are subjected to wet weak magnetic separation with a magnetic field strength of 240kA / m. Obtained iron ore concentrate yield 17.92%, TiO 2 content of 19.48%, TFe content of 54.67%, TFe recovery rate of 25.85%; titanium concentrate yield of 82.08%, TiO 2 Content 48.35%, FeO content 35.81%, Fe 2 o 3 Content 9.13%, TiO 2 The recovery rate is 91.92%. (See the process Figure 4 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com