Static characteristic detection device and measurement method specially for numerical-control pivot angle cutter head

A detection device and a technology of static characteristics, applied in measuring/indicating equipment, milling machine equipment, details of milling machine equipment, etc., can solve the problems of immature device research and development, complicated stress situation of the swing angle milling head, etc., to achieve complete functions and ensure accurate The effect of sexuality and ease of use of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In conjunction with the accompanying drawings and embodiments, a special static characteristic detection device and measurement method for a numerically controlled swing angle milling head proposed by the present invention are described in detail:

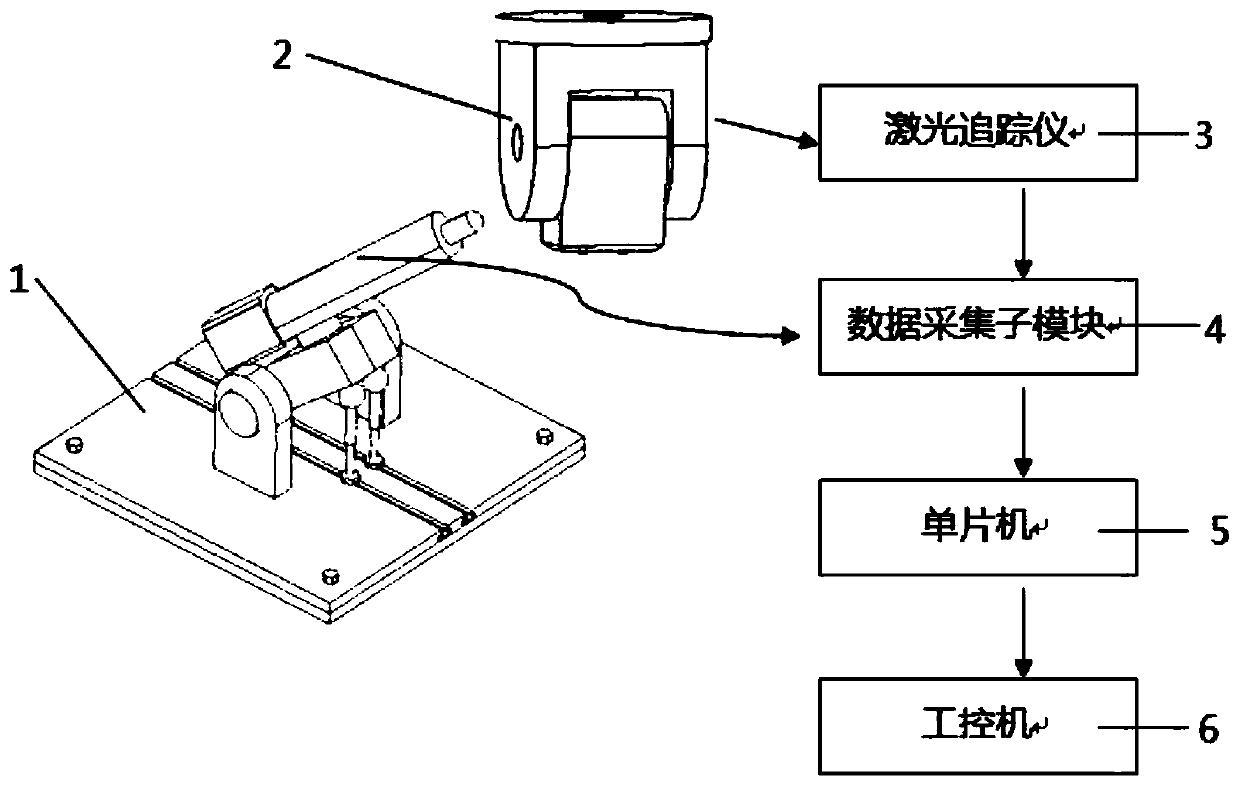

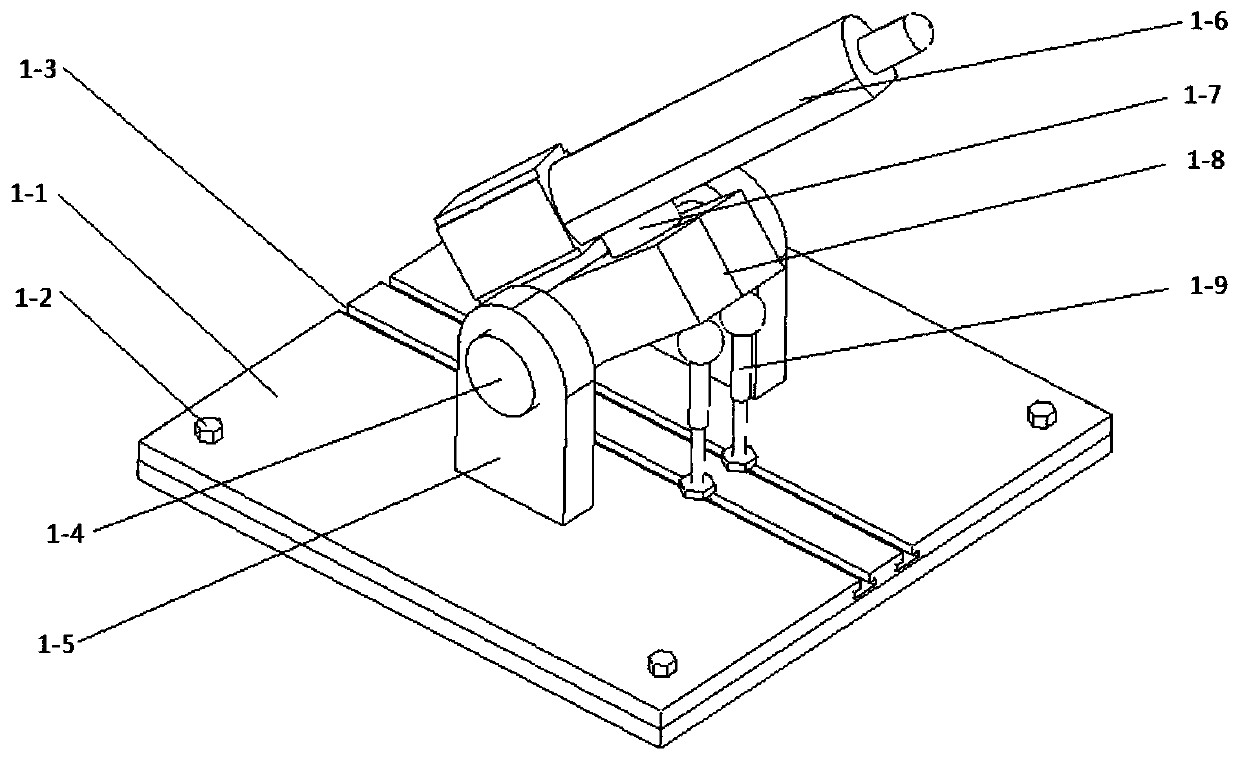

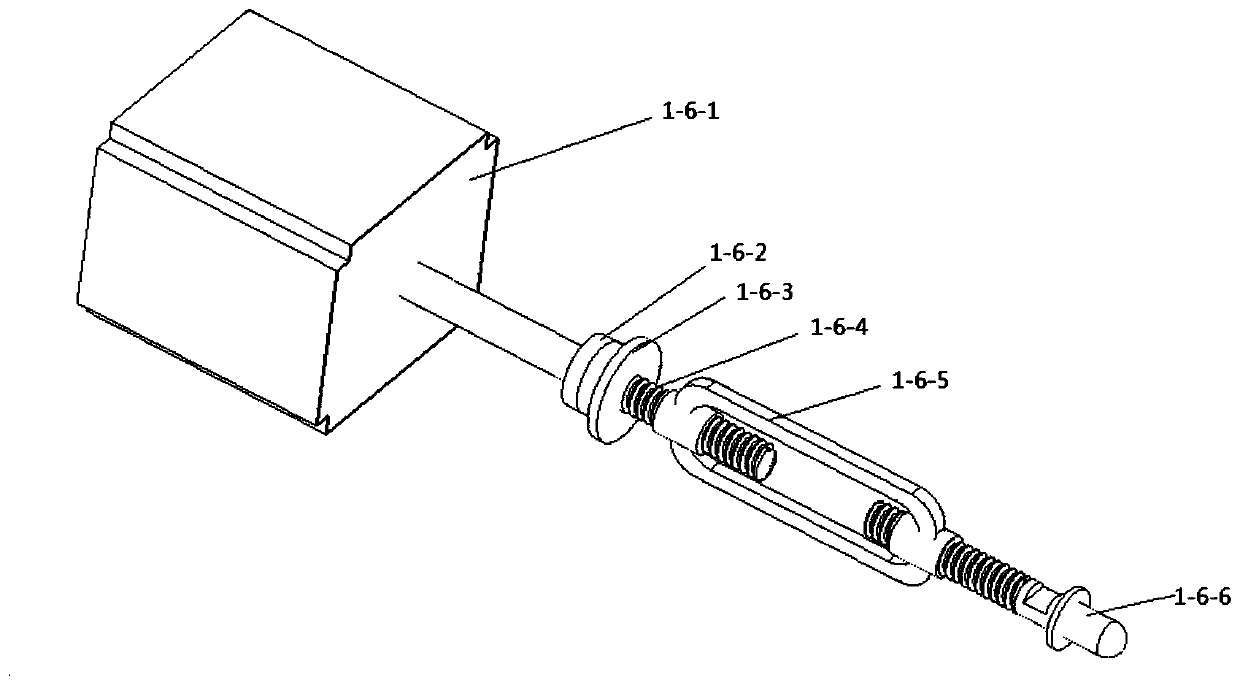

[0029] The overall application scenario of the static characteristic detection device of the present invention is as follows: figure 1 As shown, it includes a load applying structure 1 , an oscillating milling head 2 , a laser tracker 3 , a data acquisition sub-module 4 , a single-chip microcomputer 5 and an industrial computer 6 . Wherein the force sensor 1-6-7 in the load application mechanism 1 and the signal output end of the laser tracker 3 are connected with the signal input end of the data acquisition sub-module 4, and the signal output end of the data acquisition sub-module 4 is connected with the signal of the single-chip microcomputer 5 The input ends are connected, and the signal output end of the single-chip micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com