Novel run-flat tire

A run-flat tire, a new type of technology, applied to tire parts, transportation and packaging, vehicle parts, etc., to achieve the effect of high safety, low requirements, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

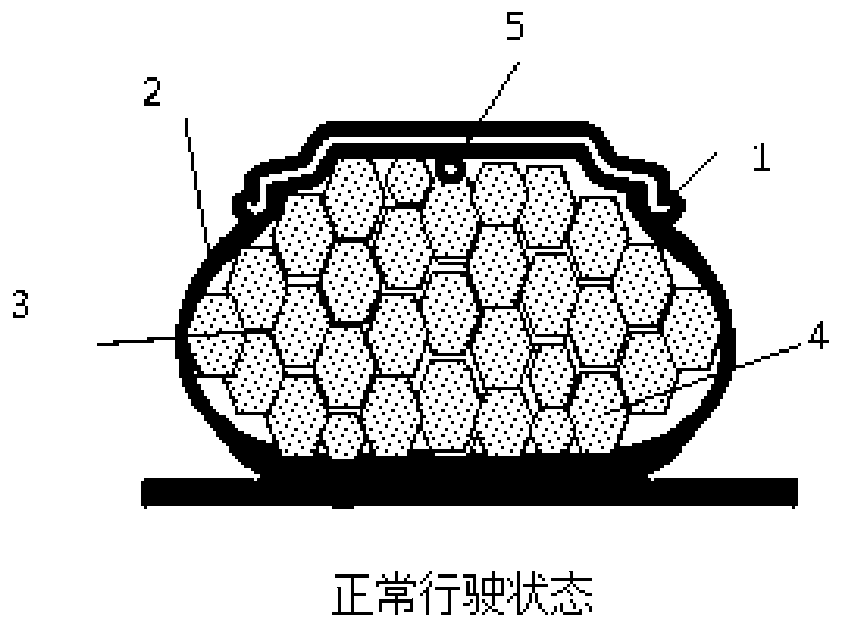

[0021] A new type of run-flat tire, such as figure 1 As shown, it is mainly composed of hub 1, carcass 2, filler 3, gas 4 and inflation conduit 5 and other components.

[0022] The filler is wrapped by the carcass and fits closely with the hub, and the filler is filled with gas; the inflation conduit is set inside the hub.

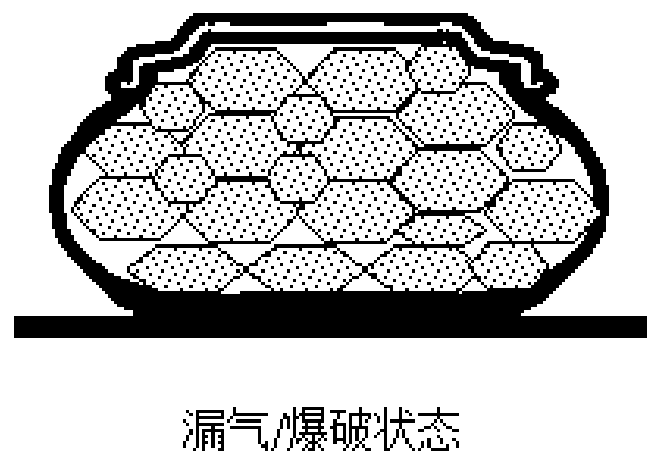

[0023] Among them, the inner filler of the tire is a belt-shaped ring composed of light, high-strength, and high-elastic polymer composite materials similar to honeycomb foam; the filler has been optimized and has high strength and high elasticity. When it is damaged due to air leakage or blasting, it can play a strong supporting role to ensure that the tire does not produce large deformation in the vertical and lateral directions, maintain good rolling performance, and ensure that the vehicle / aircraft can roll normally.

[0024] Further, each bubble body in the filler can communicate with each other, so that the gas can reach each bubble body.

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com