Organic fertilizer processing method for improving oxygen content of processing raw materials

A technology for processing raw materials and a processing method, which is applied in the field of organic fertilizer processing for improving the oxygen content of the raw materials, can solve the problems of long fermentation time, poor aerobic fermentation effect, low organic fertilizer production efficiency, etc. The effect of destroying and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

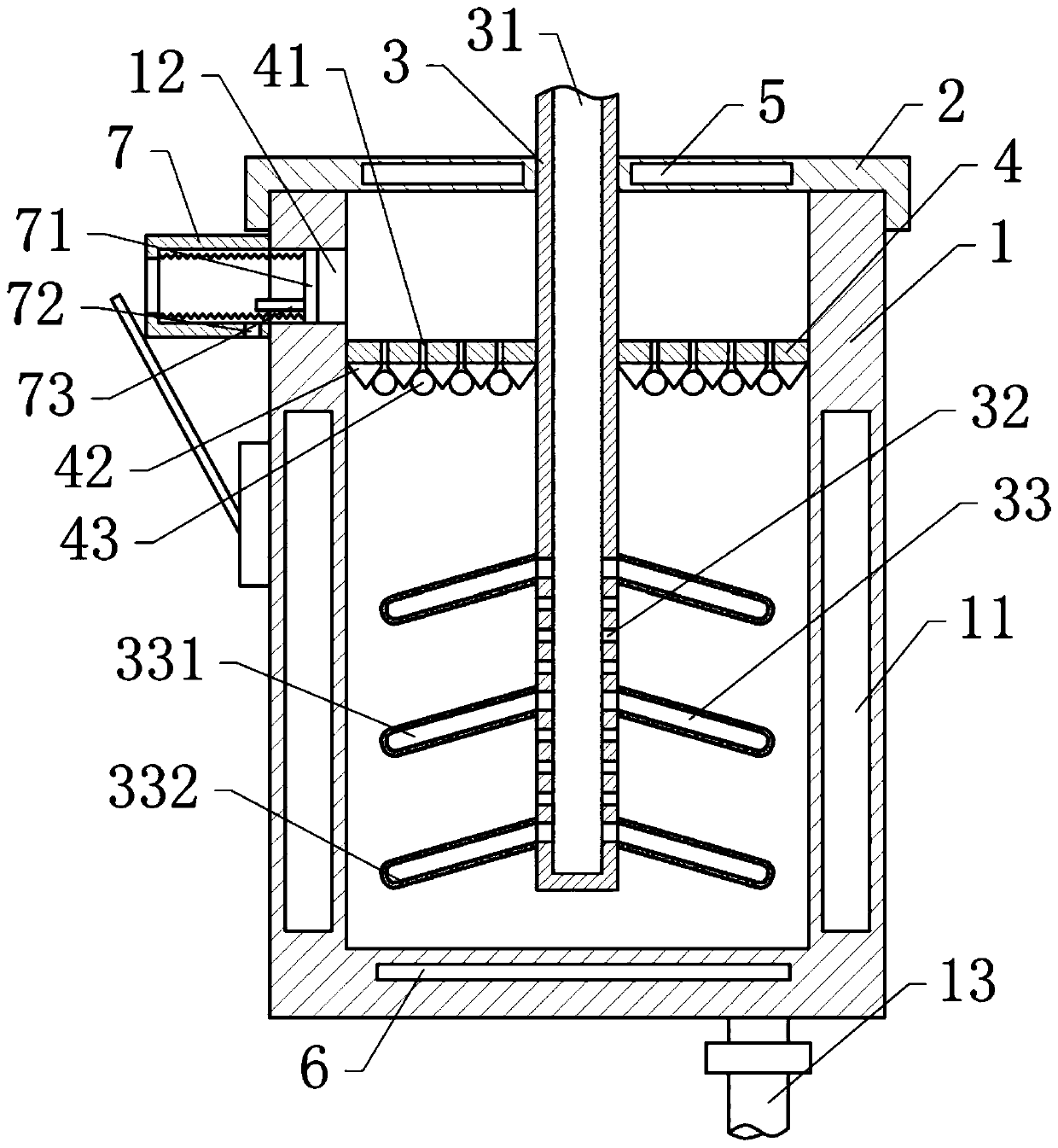

[0036] The fermentation device used in this embodiment is basically as attached figure 2 As shown, it includes a bracket and a fermenter 1 fixed on the bracket. The top of the fermenter 1 is covered with a sealing cover 2. The sealing cover 2 includes two spliced sub-boards, which form a rotating hole after splicing. A stirring shaft 3 is rotatably connected to the support, and the stirring shaft 3 can be vertically slidably connected to the support. The specific connection method is that the support is rotatably connected with a rotating ring, and the stirring shaft 3 is splined with the rotating ring. The stirring shaft 3 is driven by a motor. The specific setting is that the motor is fixed on the bracket, and the output shaft of the motor is fixed with a driving gear. The stirring shaft 3 is provided with a driven gear at the top of the sealing cover 2. engage.

[0037] The stirring shaft 3 is rotatably connected in the rotating hole formed by the sealing cover 2, and a...

Embodiment 2

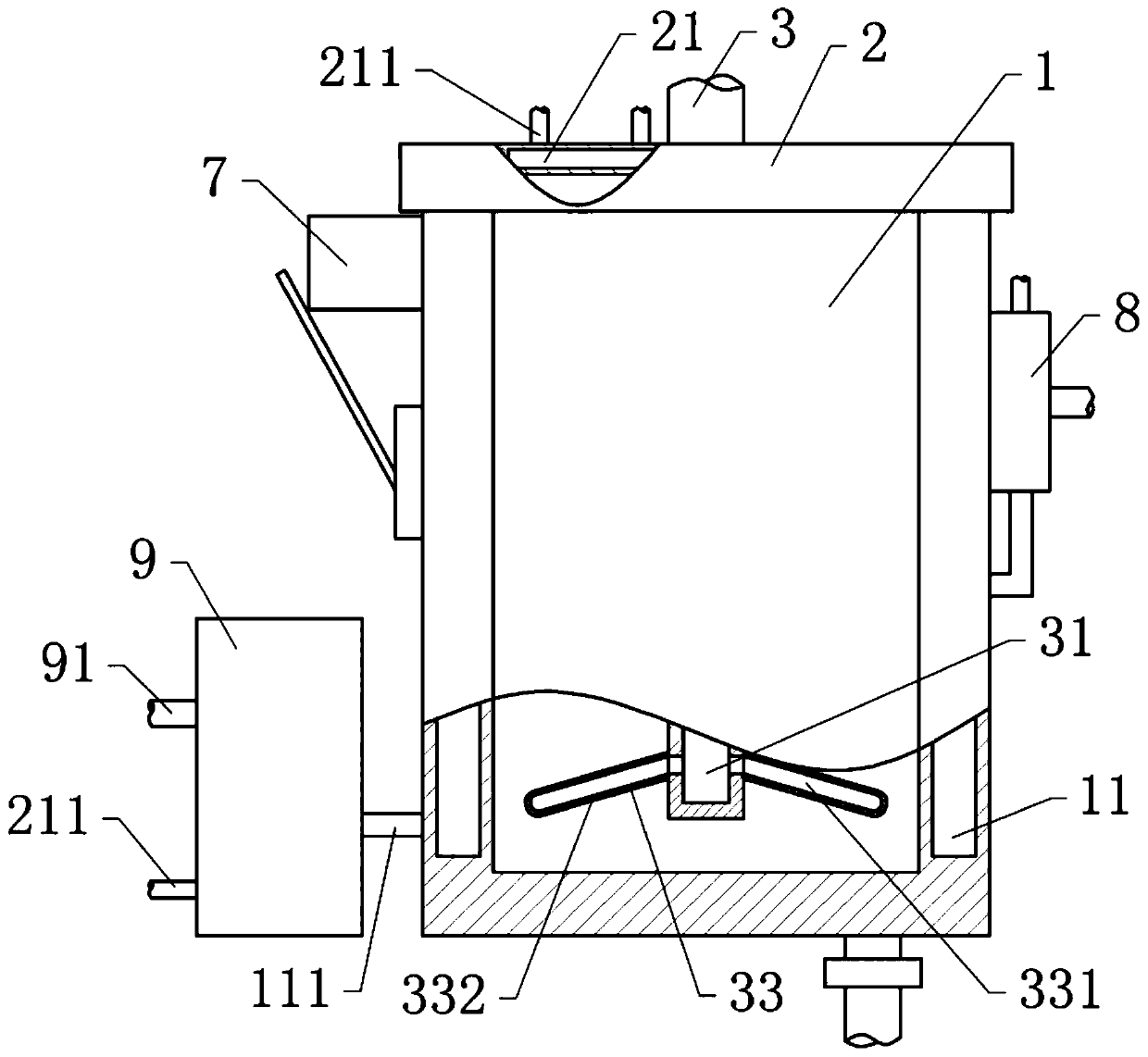

[0053] Embodiment 2 differs from Embodiment 1 only in that, as image 3 As shown, the present embodiment is different from the gas-filling mechanism used in Embodiment 1. The gas-filling mechanism includes a compressed gas box and a vortex tube 8 fixed on the bracket. One end communicates with the intake end of the vortex tube 8 .

[0054] The side wall of fermentation tank 1 is provided with insulation cavity 11, and the hot flow end of vortex tube 8 communicates with insulation cavity 11; The cooling cavity 21 communicates. A storage box 9 is also fixed on the bracket, a first flow guide tube 111 is communicated between the heat preservation cavity 11 and the storage box 9, a second flow guide tube 211 is communicated between the cooling cavity 21 and the storage box 9, and the first Both the guide pipe 111 and the second guide pipe 211 are provided with one-way valves, and when the pressure in the heat preservation cavity 11 and the cooling cavity 21 is relatively high, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com