Preparation process of fine denier high-elasticity rib fabric

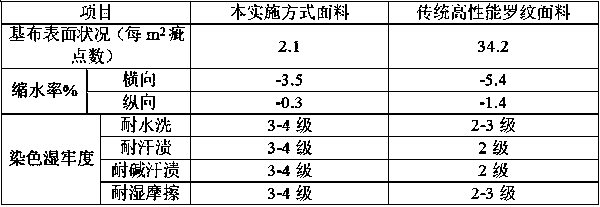

A preparation process and high elasticity technology, applied in the textile field, can solve the problems of difficult weaving and dyeing and finishing, poor functionality, low wet fastness, etc., and achieve the effect of shortening the post-processing process, compact structure, and good horizontal and vertical elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0053] This embodiment provides a preparation process for a fine denier high elastic ribbed fabric, comprising the following steps:

[0054] Step 1, use DTY semi-gloss nylon yarn with specifications of 10D / 12F and 20D dyeable spandex high elastic yarn as raw materials to weave nylon spandex double-sided rib fabric;

[0055] Step 2, pre-treatment, using open-width washing, high-temperature preliminary continuous production, passing the fabric into the open-width degreasing machine, an ultrasonic instrument is installed on the outer circumference of the open-width degreasing machine, and the internal temperature is 50-85°C Pure water, nitrogen gas is passed through the pure water continuously, the ultrasonic instrument for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com