Surface patterning manufacturing method of biological protein film

A technology of biological protein and production method, which is applied in the biological field to achieve the effect of simple operation, high resolution and high direct writing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

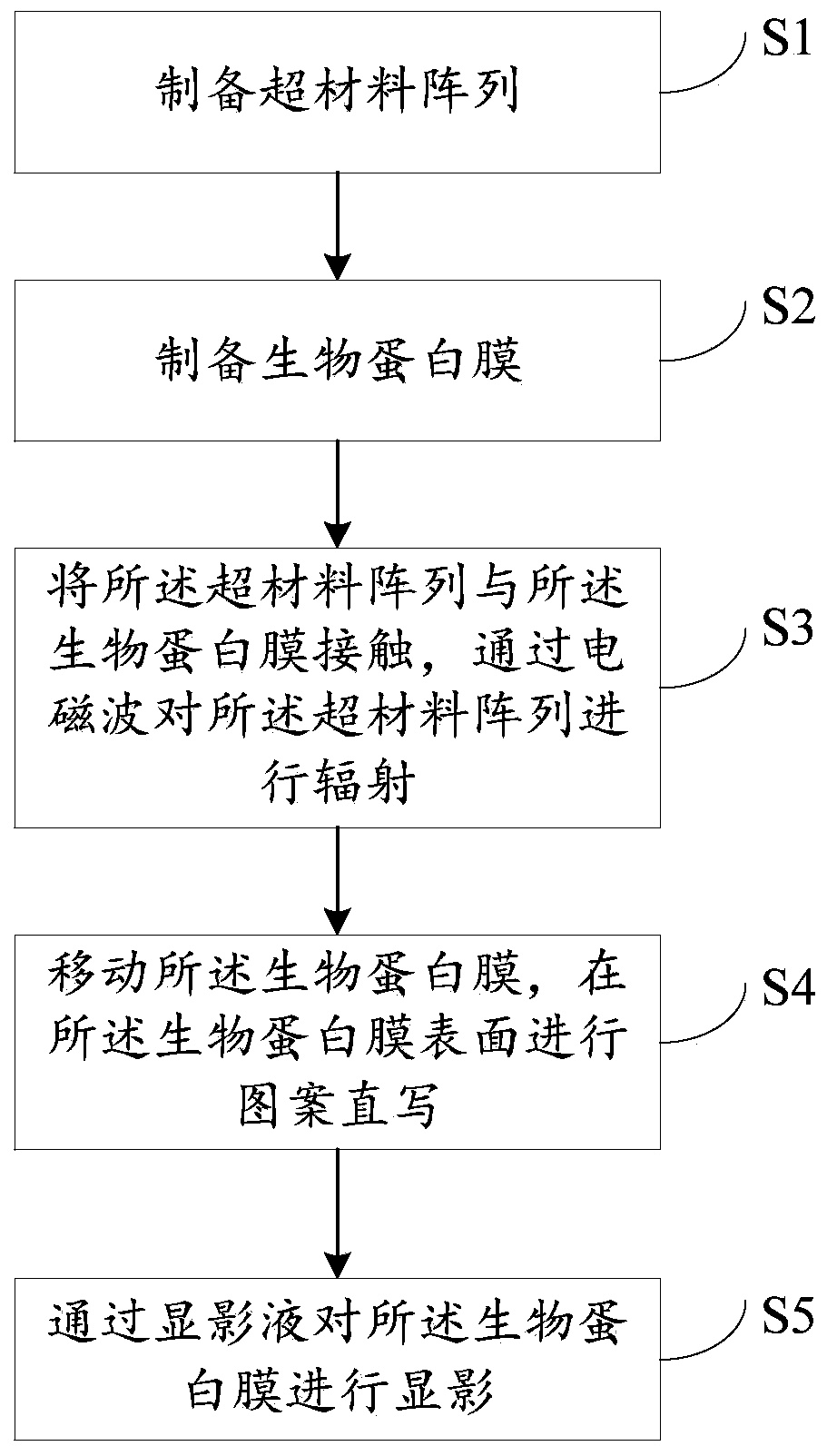

[0059] The embodiment of the present invention provides a method for fabricating a patterned surface of a biological protein film, such as figure 1 As shown, the method includes the following steps:

[0060] S1. Prepare metamaterial array;

[0061] S2. prepare biological protein film;

[0062]S3. Contacting the metamaterial array with the biological protein film, and irradiating the metamaterial array through electromagnetic waves;

[0063] S4. moving the biological protein film, and directly writing patterns on the surface of the biological protein film;

[0064] S5. developing the biological protein film with a developing solution.

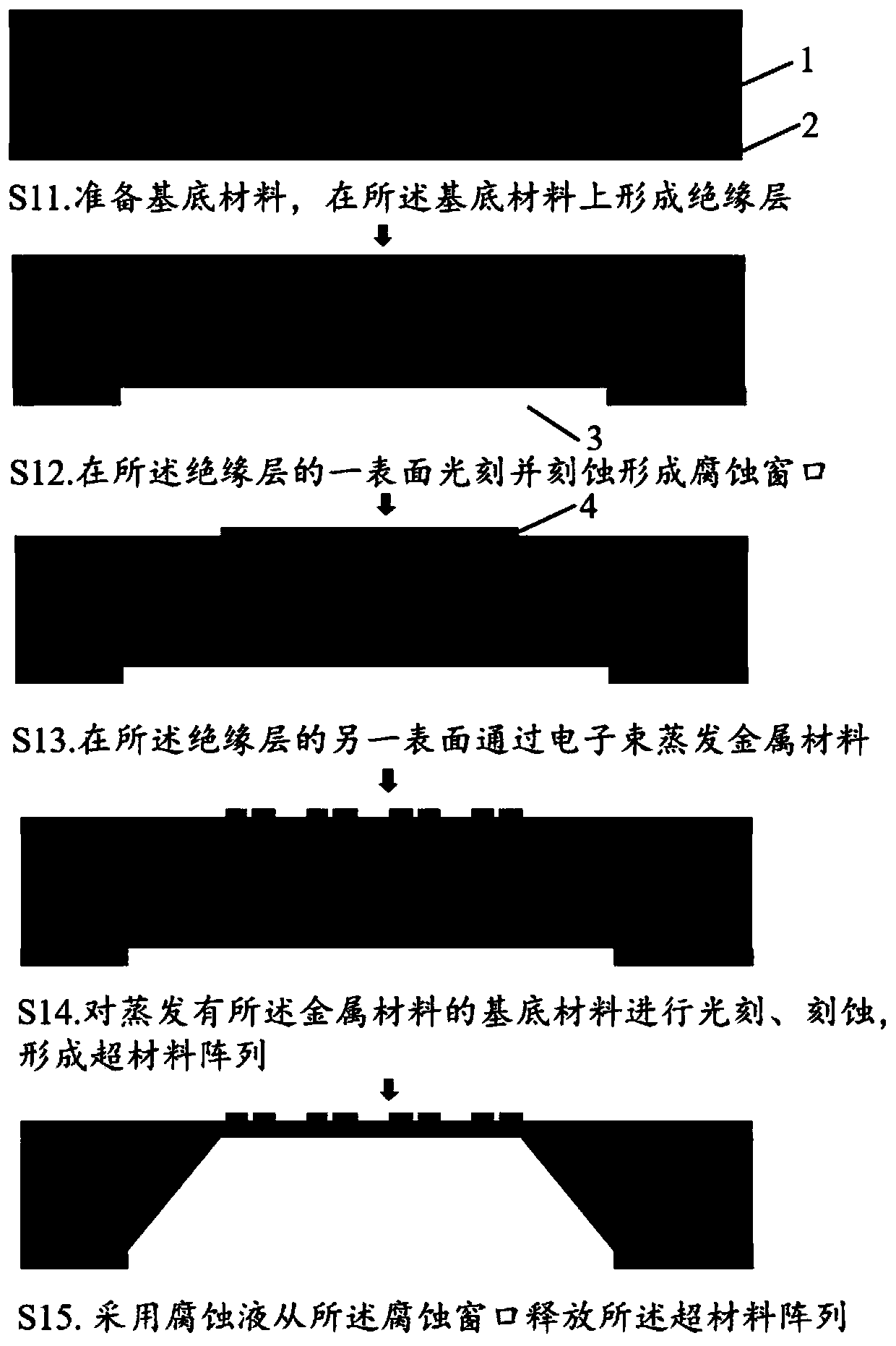

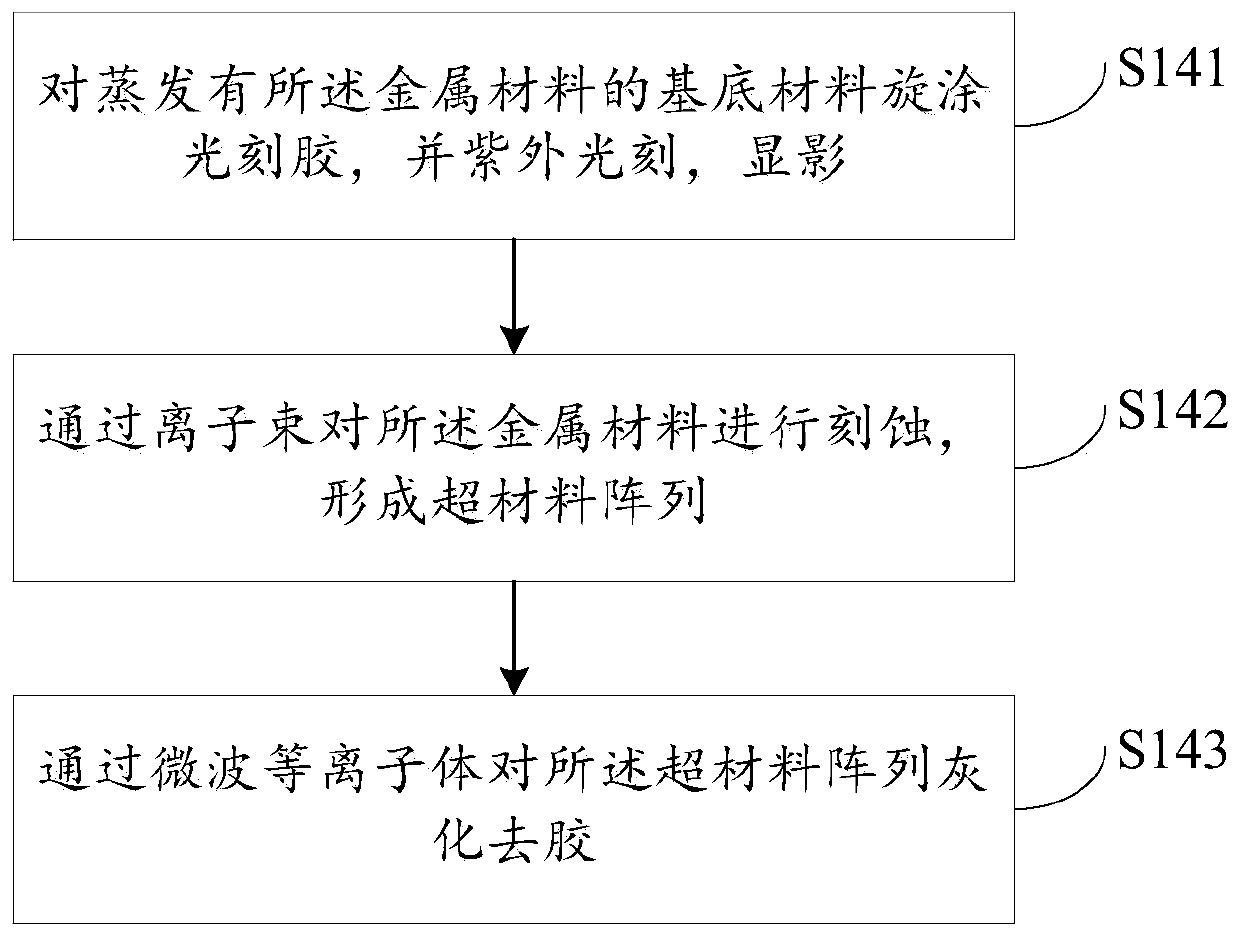

[0065] In the embodiment of the present invention, such as figure 2 As shown, the step S1 may include the following steps:

[0066] S11 . Prepare a base material 1 , and form an insulating layer 2 on the base material 1 .

[0067] In some embodiments, the base material 1 may be a double-polished silicon wafer.

[0068] In some embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com