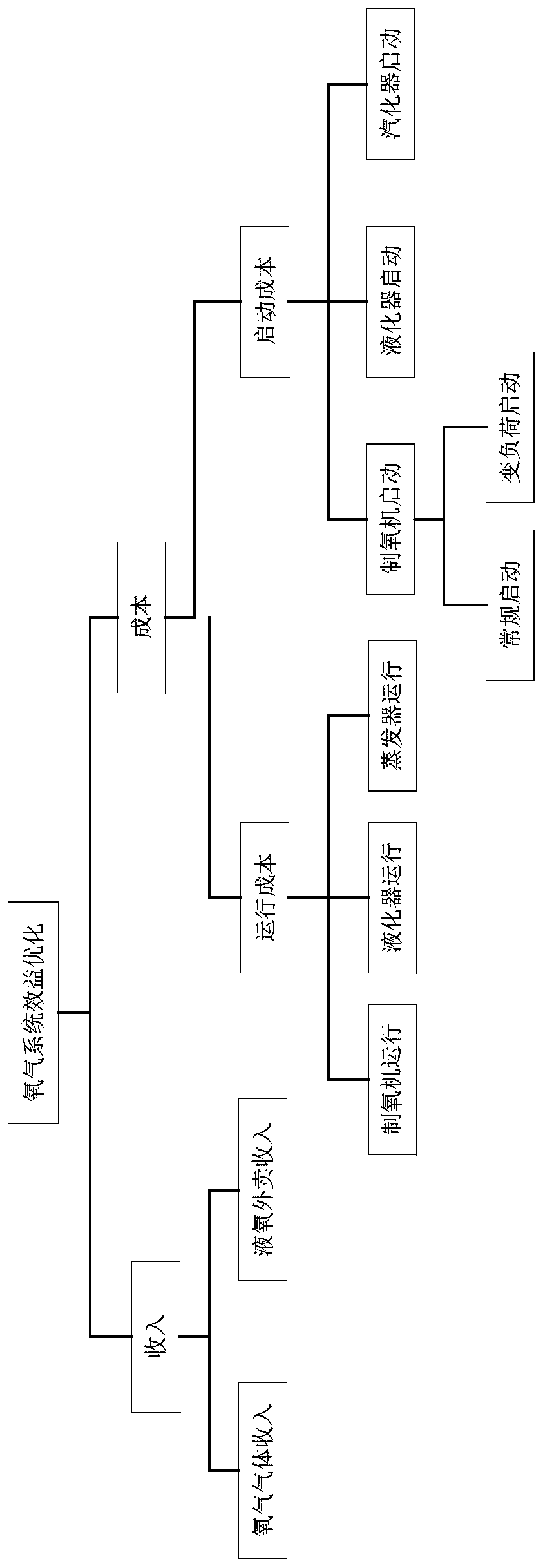

Cost optimization method for oxygen system of iron and steel enterprise

An oxygen system and cost-optimized technology, applied in general control systems, control/regulation systems, energy industries, etc., can solve problems such as waste of resources and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

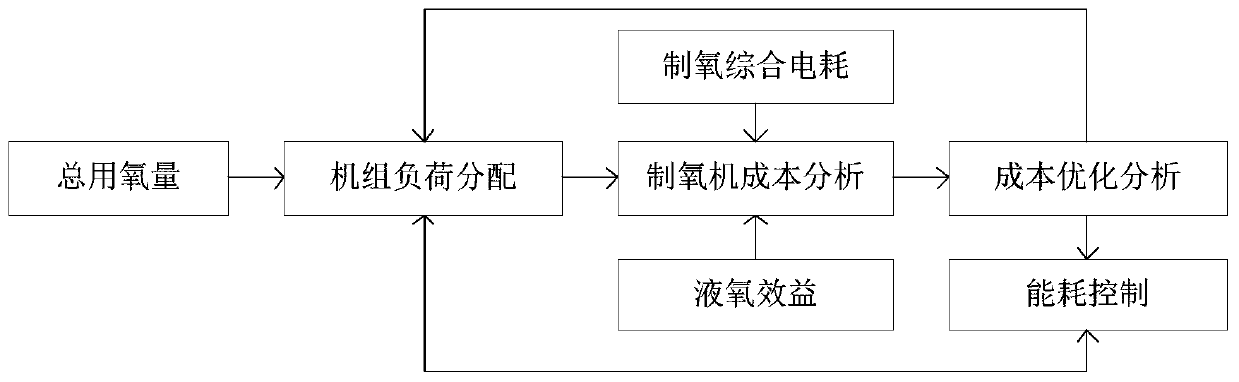

Method used

Image

Examples

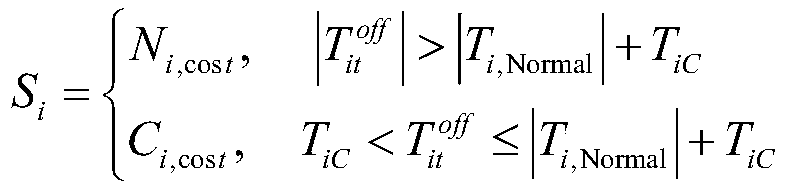

Embodiment Construction

[0072] An example is given below, and the specific implementation manner of the present invention is further described in detail.

[0073] The 24-hour oxygen system production data of a steel company is used to verify the optimization effect of the model. The iron and steel enterprise currently has 75000Nm 3 / h 2 sets of oxygen generators, 3 liquid storage tanks (4000m 3 Liquid oxygen, 4000m 3 Liquid nitrogen, 1000m 3 One liquid argon storage tank), 5 oxygen spherical tanks, 2 medium-pressure nitrogen balloon tanks, 3 low-pressure nitrogen balloon tanks, and 1 argon balloon tank. Oxygen reserve capacity is 75000Nm 3 / h, the backup capacity of low pressure nitrogen is 52000Nm 3 / h, the backup capacity of medium pressure nitrogen is 25500Nm 3 / h, the reserve capacity of liquid argon is 2400Nm 3 / h. The operating point of the air separation unit can be within ±20000m within the range of design working conditions 3 / h range to achieve rapid load changes. The model takes ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap