Activation method of fuel cell stack

A fuel cell stack and activation method technology, applied in the field of fuel cell stack activation, can solve the problems of increasing fuel hydrogen consumption, increasing activation operating costs, etc., and achieve the effect of shortening activation time and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

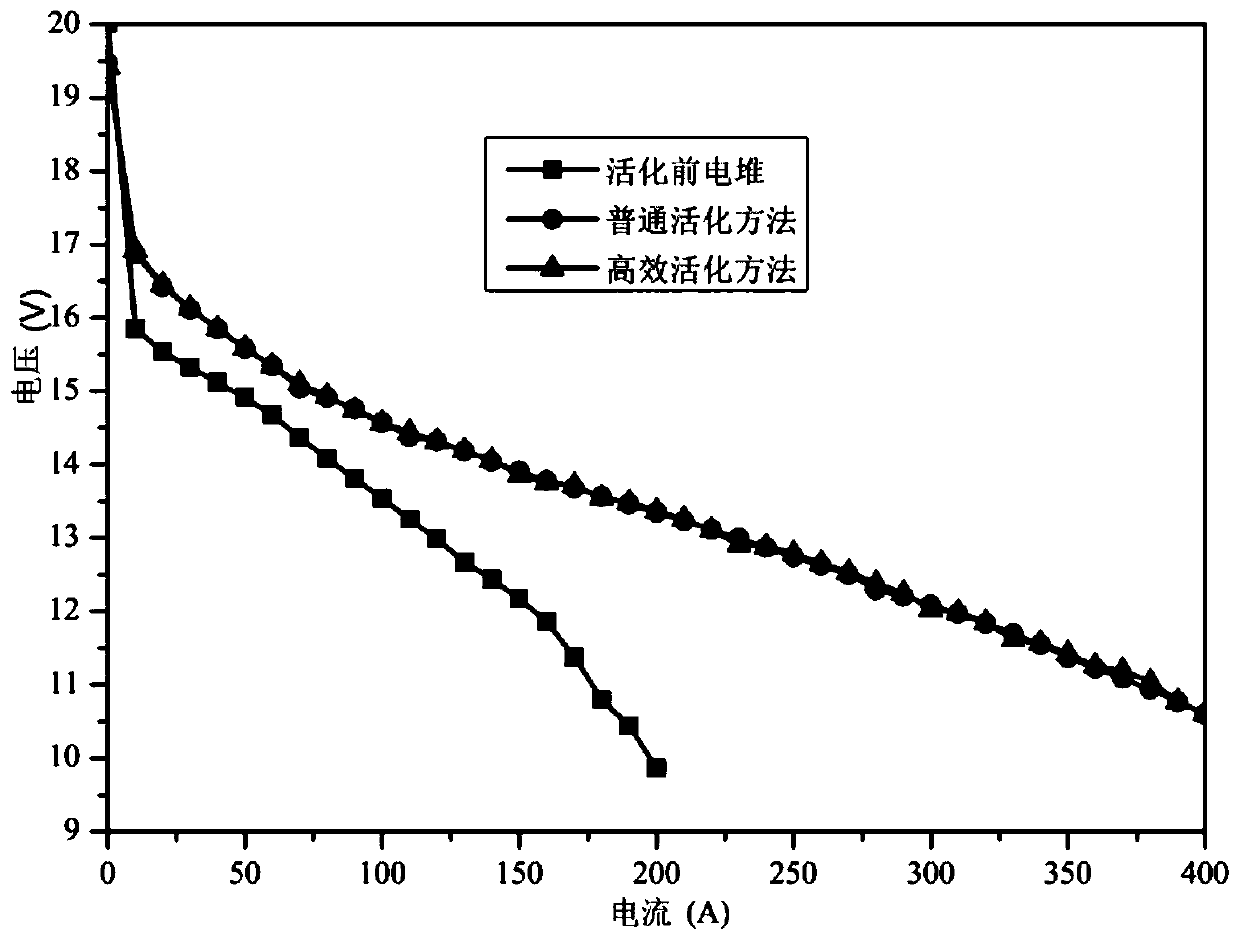

Embodiment 1

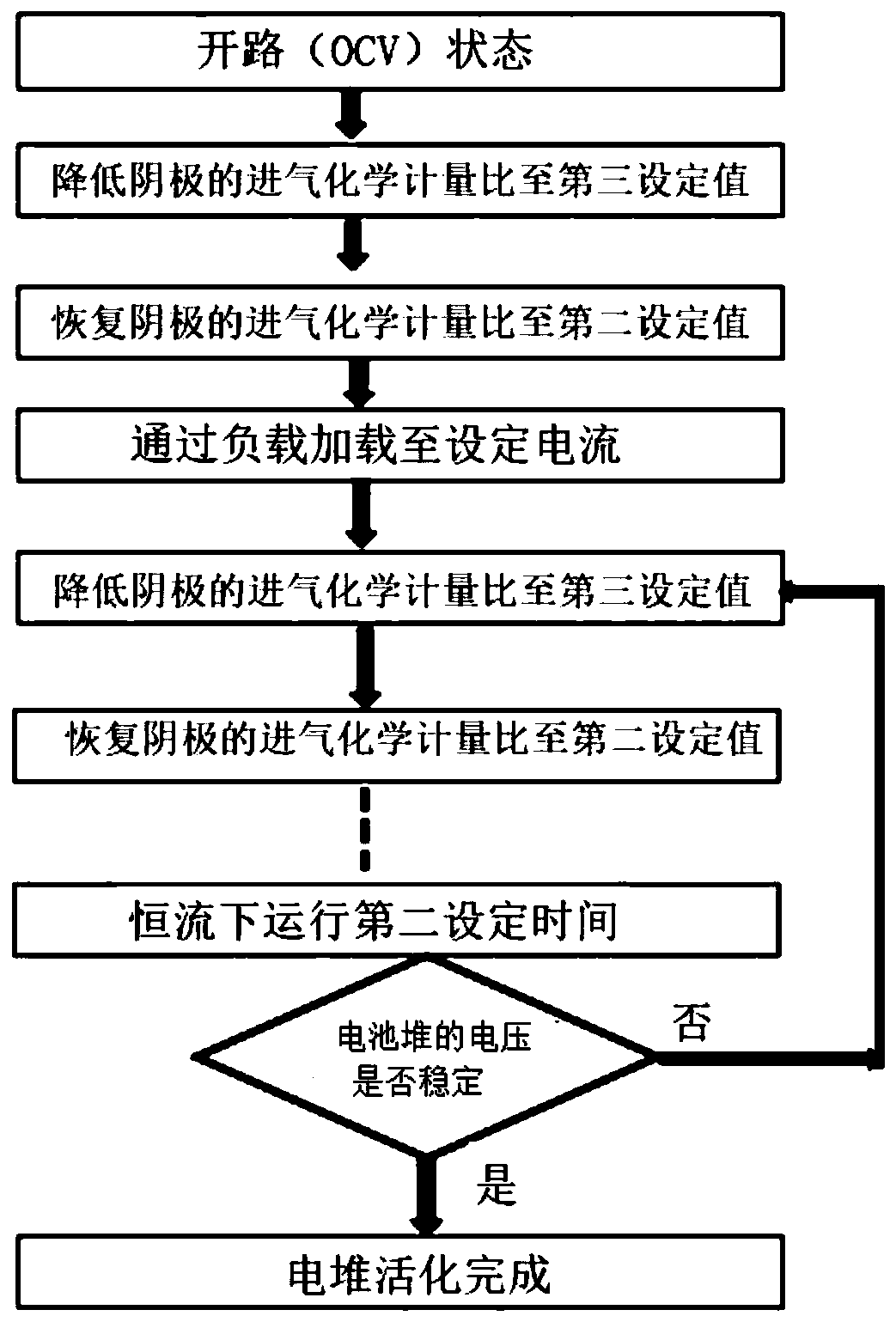

[0054] In this embodiment, the fuel cell stack including 20 single cell stacks is activated, which specifically includes the following steps:

[0055] Step S0: install the battery stack to be activated that meets the air tightness test standard on the test platform, and connect the gas pipeline, cooling water pipeline and electronic load. Start the load so that the test platform can communicate with the load. Set the preheating temperature of the test platform water tank, turn on the water pump, and preheat the stack to be activated. Set the temperature of each pipeline, feed N 2 The cathode and anode of the stack are purged.

[0056] Step S1: After the purging is completed, select the manual test mode, and pass H to the anode and cathode of the battery stack respectively. 2 and air to ensure that the stack to be activated is in an open-circuit state (OCV); wherein, the stoichiometric ratio of the anode’s hydrogen intake is set to 1.5, and the stoichiometric ratio of the ca...

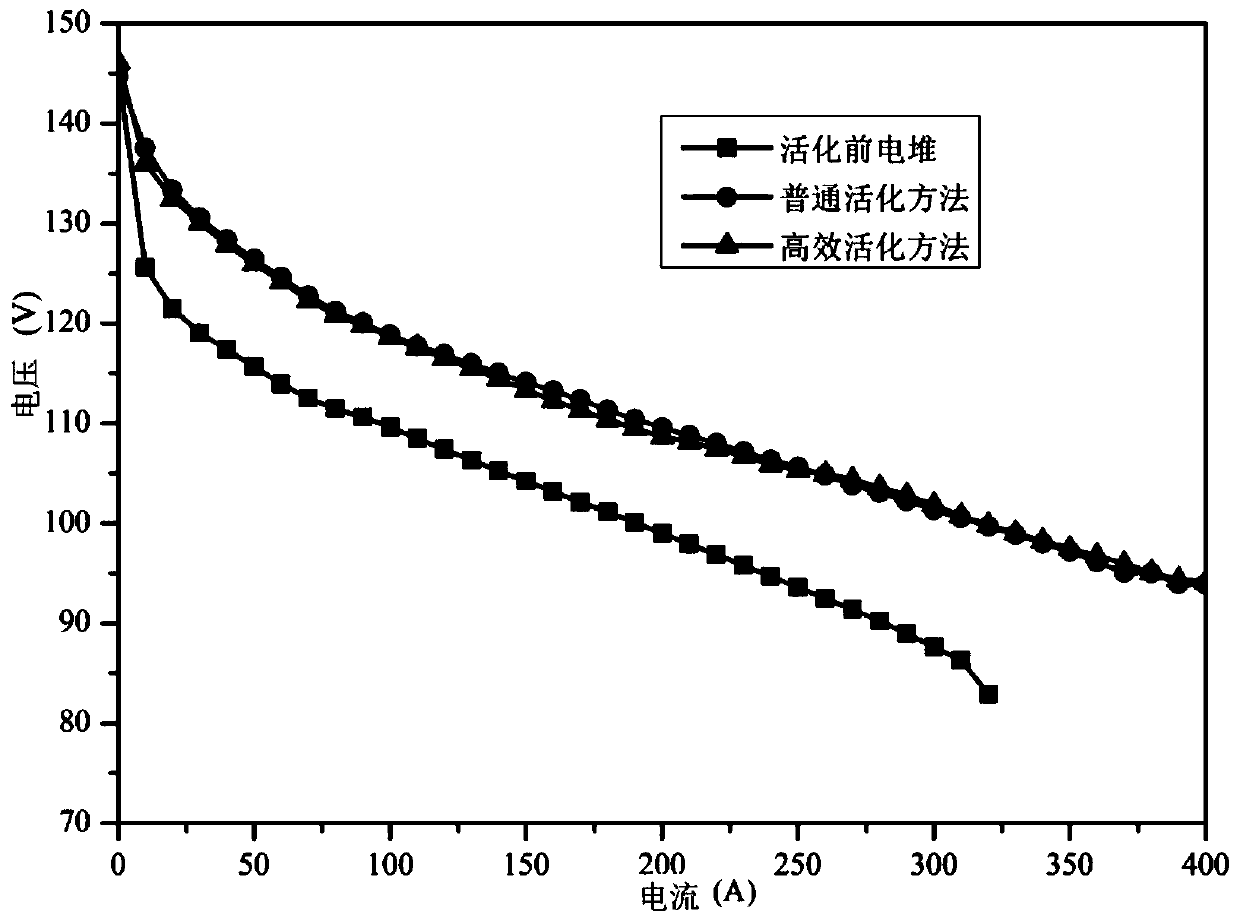

Embodiment 2

[0065] In this embodiment, the fuel cell stack including 160 single cell stacks is activated, which specifically includes the following steps:

[0066] Step S0: install the battery stack to be activated that meets the air tightness test standard on the test platform, and connect the gas pipeline, cooling water pipeline and electronic load. Start the load so that the test platform can communicate with the load. Set the preheating temperature of the test platform water tank, turn on the water pump, and preheat the stack to be activated. Set the temperature of each pipeline, feed N 2 The cathode and anode of the stack are purged.

[0067] Step S1: After the purging is completed, select the manual test mode, and pass H to the anode and cathode of the battery stack respectively. 2 and air to ensure that the stack to be activated is in an open-circuit state (OCV); wherein, the stoichiometric ratio of the anode’s hydrogen intake is set to 1.5, and the stoichiometric ratio of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com