Motor driving circuit and motor driving device

A technology for driving circuits and motors, used in motor control, AC motor control, printed circuits, etc., can solve problems such as difficulty in accurately measuring the current flowing through wiring patterns, and inability to further improve motor rotation control accuracy. Abnormal heat generation and damage, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

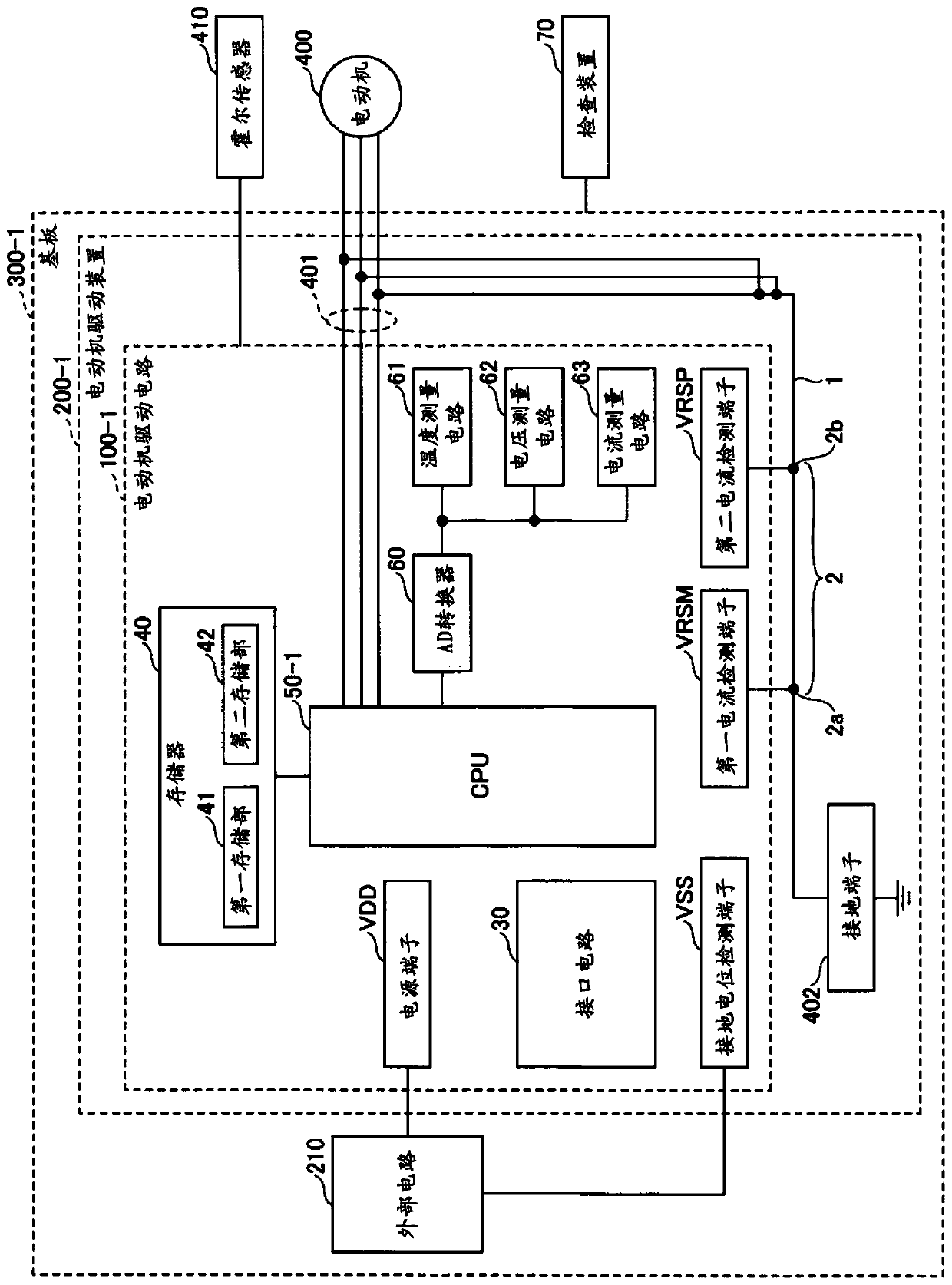

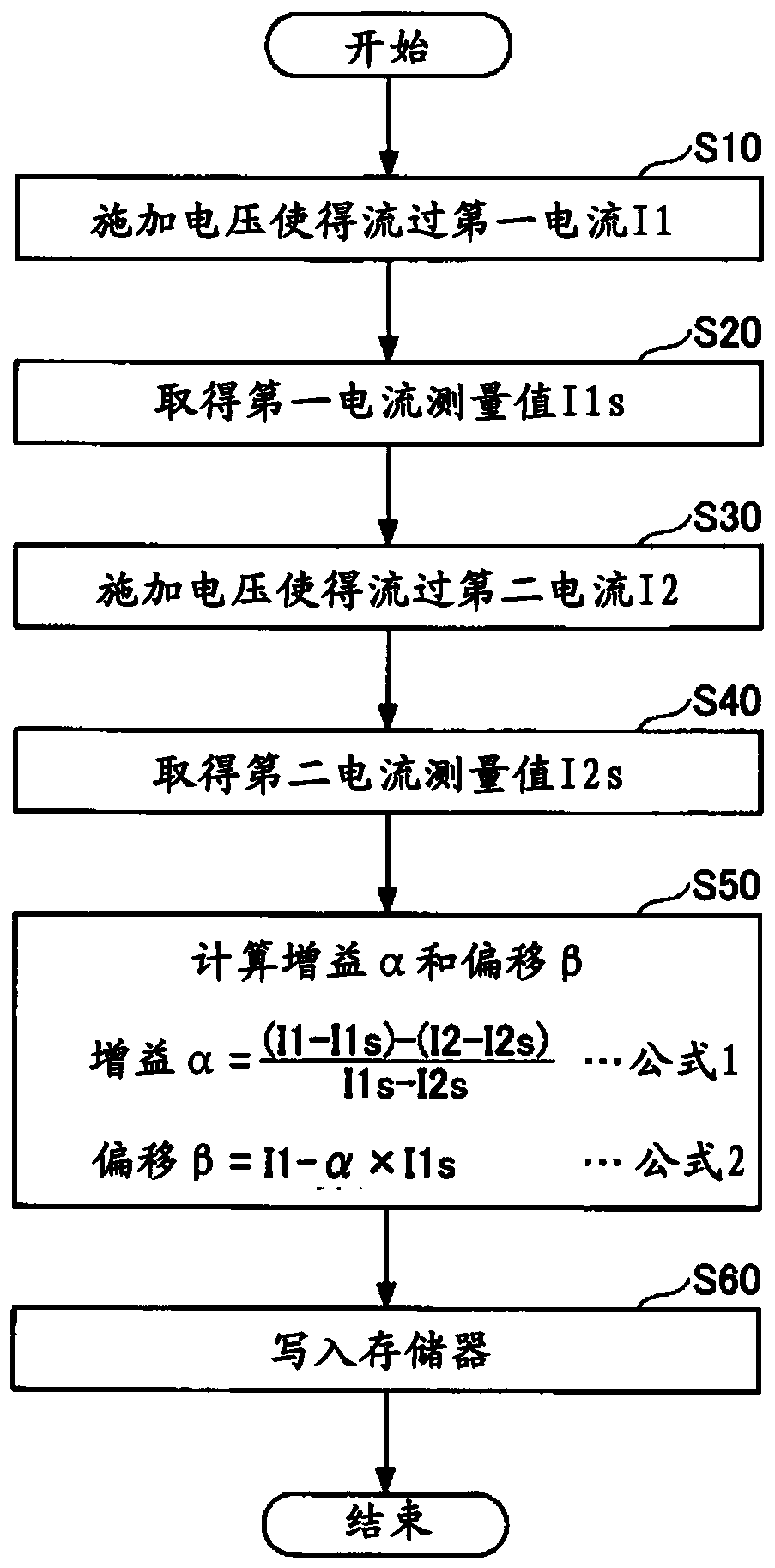

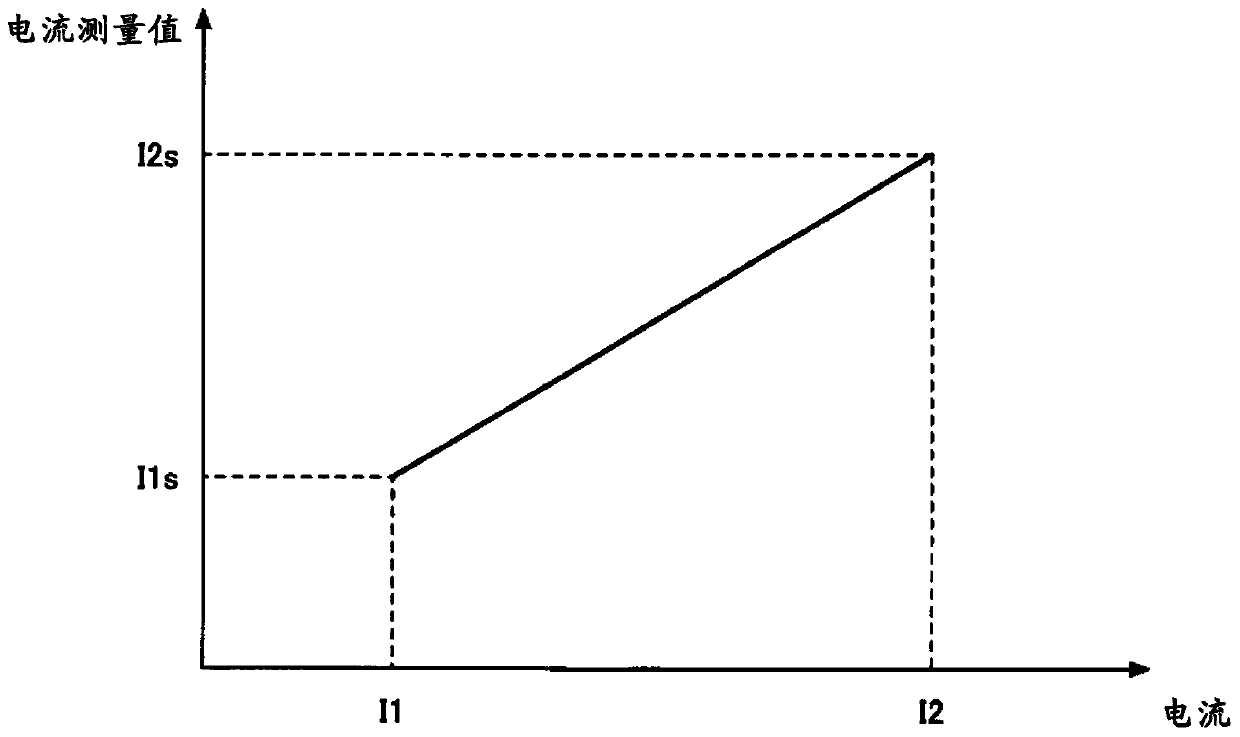

[0020] figure 1 The configuration of the motor drive device according to Embodiment 1 of the present invention is shown. figure 1 The motor drive device 200-1 of Embodiment 1 and the external circuit 210 are provided in the illustrated substrate 300-1. The substrate 300-1 is, for example, a printed circuit board made of glass epoxy resin. The motor drive device 200-1 includes a motor drive circuit 100-1 that measures the current flowing through the wiring pattern 1 formed on the substrate 300-1, and drives the motor based on the measured current value. The wiring pattern 1 is a copper foil pattern formed on the substrate 300-1. One end of the wiring pattern 1 is connected to the motor wiring 401 , and the other end of the wiring pattern 1 is grounded via a ground terminal 402 . One end of the motor wiring 401 is connected to the CPU 50 - 1 , and the other end of the motor wiring 401 is connected to the motor 400 . For example, a three-phase alternating current is transmitt...

Embodiment approach 2

[0046] Figure 7 The configuration of the motor drive device according to Embodiment 2 of the present invention is shown. Hereinafter, the same reference numerals are attached to the same parts as those in Embodiment 1, and description thereof will be omitted, and different parts will be described. exist Figure 7 The motor drive device 200-2 and the external circuit 210 according to Embodiment 2 are provided on the substrate 300-2 shown. The substrate 300-2 is, for example, a printed circuit board made of glass epoxy resin. The motor drive device 200-2 includes a motor drive circuit 100-2 that measures the current flowing through the wiring pattern 1 formed on the substrate 300-2, and drives the motor based on the measured current value.

[0047] The motor drive circuit 100-2 includes an interface circuit 30, a memory 40, a CPU 50-2, an AD converter 60, a temperature measurement circuit 61, a thermistor measurement circuit 61A, a voltage measurement circuit 62, a current m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com