Activation washing equipment

A technology for cleaning equipment and cleaning tanks, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as quality reduction, easy pollution of the environment, secondary pollution, etc., to improve production quality, Improve economic efficiency and save labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

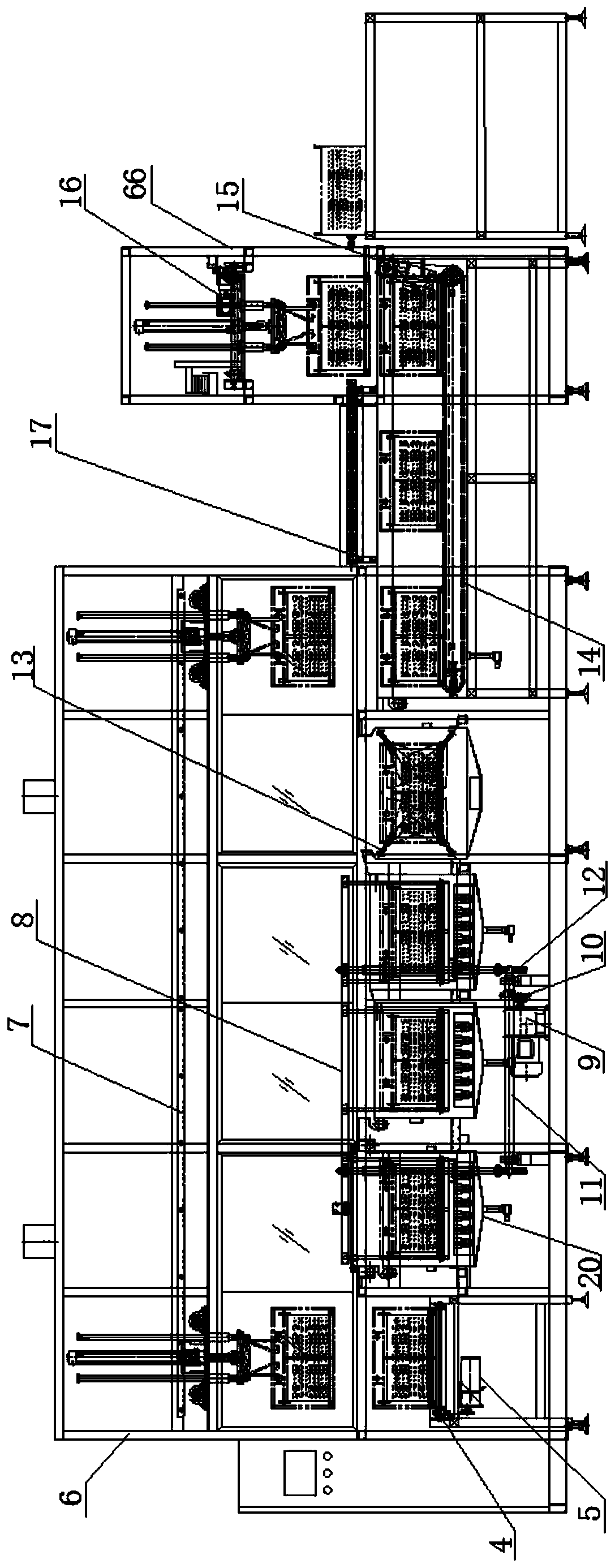

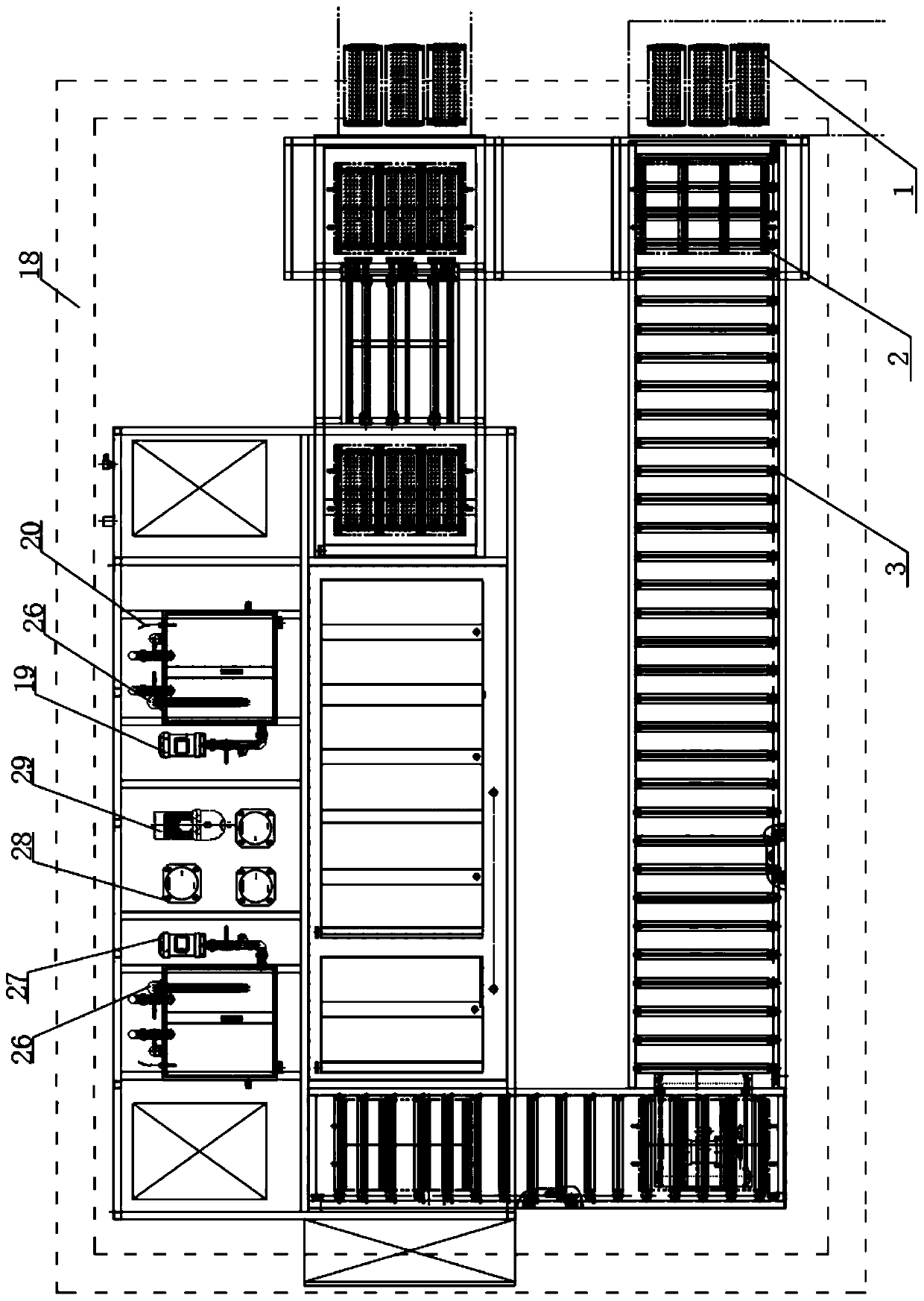

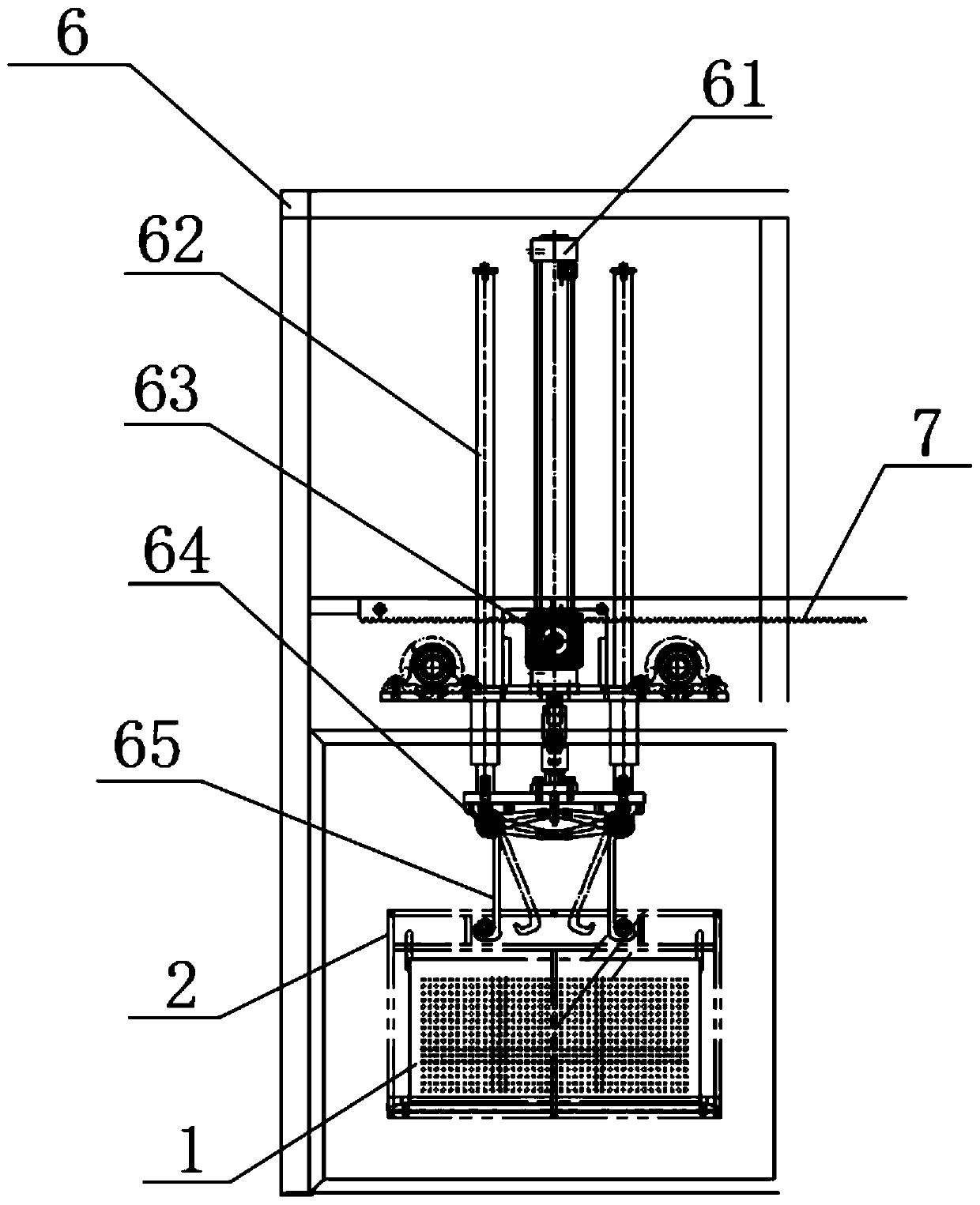

[0028] Such as Figure 1-4 As shown, a kind of activated cleaning equipment includes a sub-basket 1, a mother basket 2, a first manipulator 6, a second manipulator 66, a drainage ditch 18, a feeding station, an ultrasonic cleaning station, a spraying station, and a soaking and discharging station. Station,

[0029] The feeding station includes a transmission chain 3 and a feeding platform 4, the transmission chain 3 communicates with the feeding platform 4, and a first manipulator 6 is arranged above the feeding platform 4;

[0030] The ultrasonic cleaning station includes a throwing device and a cleaning device, the throwing device includes a throwing frame 8, a throwing motor 9, and a throwing connecting shaft 11, and a throwing transmission is fixedly installed on the throwing motor 9. Sprocket 10, the throwing transmission sprocket 10 is meshed with the throwing connecting shaft 11, and the two ends of the throwing connecting shaft 11 are provided with a throwing eccentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com