Metal casting mold cooling device

A mold cooling and metal casting technology, which is applied in the field of metal casting mold cooling devices, can solve the problems of limited heat, unable to meet the rapid cooling of molds, and low efficiency, and achieve the effects of recycling, large specific heat capacity, and accelerated flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

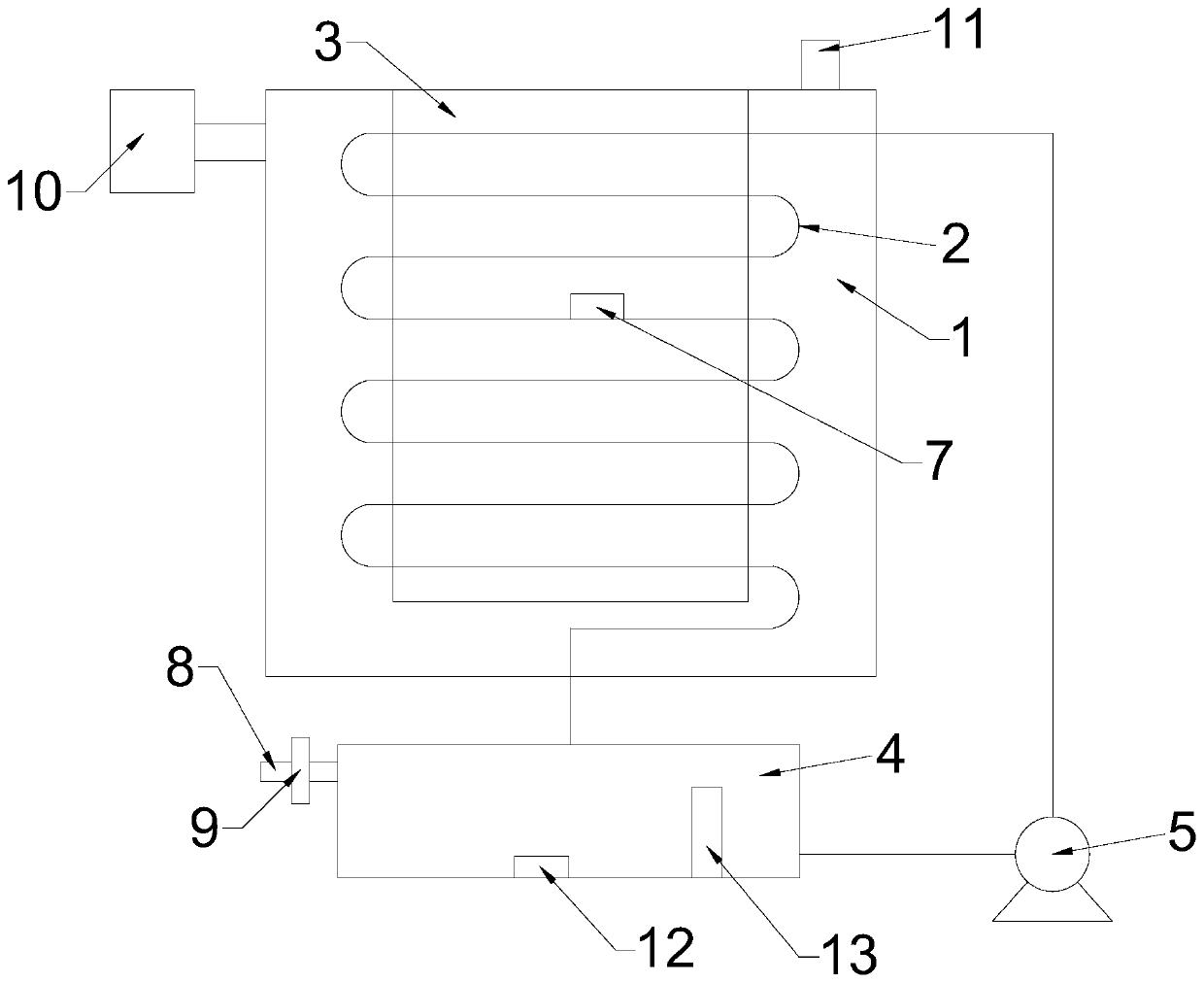

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

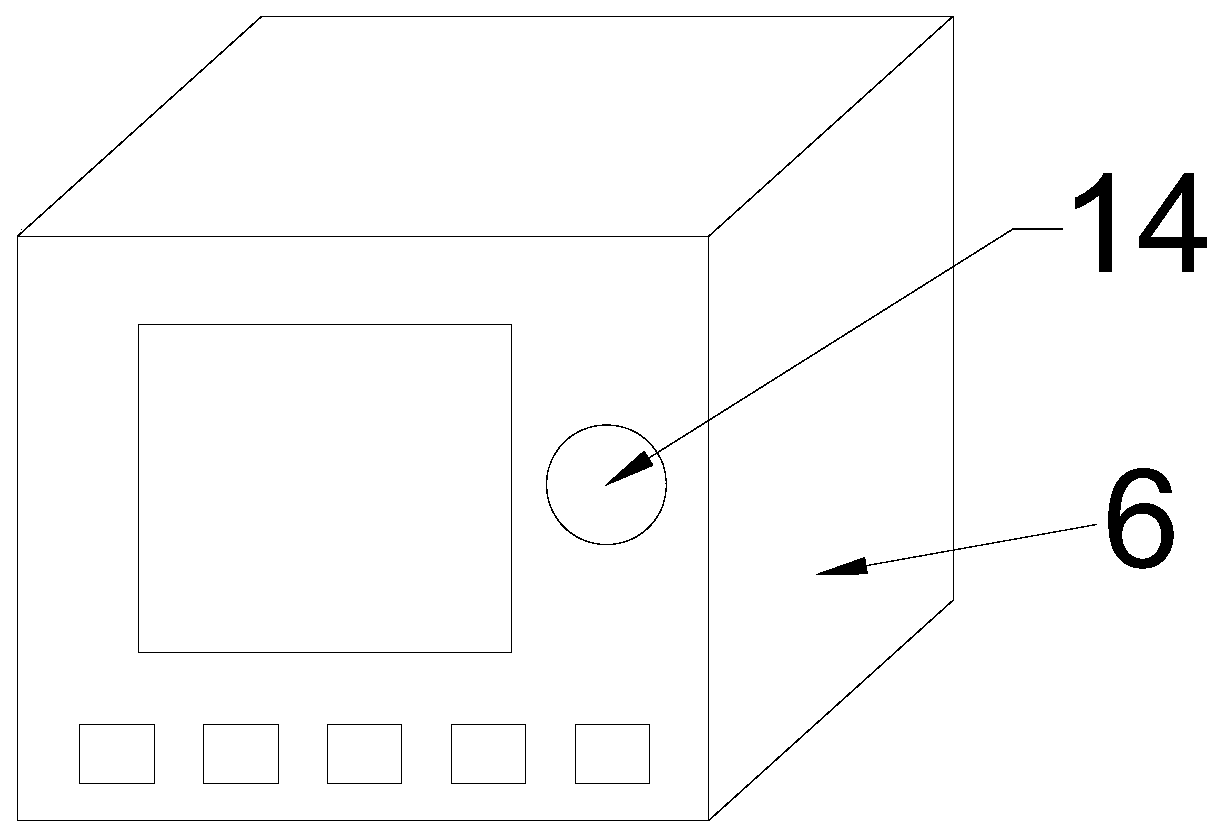

[0021] Such as figure 1 as well as figure 2 As shown, a kind of metal casting mold cooling device is provided in the embodiment,

[0022] Including box 1, cooling pipeline 2, mold groove 3, water storage tank 4, circulation pump 5 and controller 6; box 1 is a cuboid hollow structure, mold groove 3 is set on the top of box 1, and box 1 surrounds mold groove 3 The side wall and the bottom are arranged, the cooling pipe 2 is arranged inside the box body 1, the cooling pipe 2 is arranged around the mold groove 3 from top to bottom, and the cooling pipes 2 are closely connected up and down, so that the water in the cooling pipe 2 can fully surround the mold groove 3 side wall flow, the first temperature sensor 7 is set on the cooling pipeline 2, and a certain space is reserved between the cooling pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com