Cleaning method of artificial diamond

A synthetic diamond and diamond technology, applied in the direction of chemical instruments and methods, manufacturing tools, detergent compounding agents, etc., can solve the problems affecting the development of diamond, restricting the scale and quality of diamond production, harmful gases, etc., and achieve simple and convenient cleaning methods, The effect of reducing the rubbing and washing process and reducing the labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

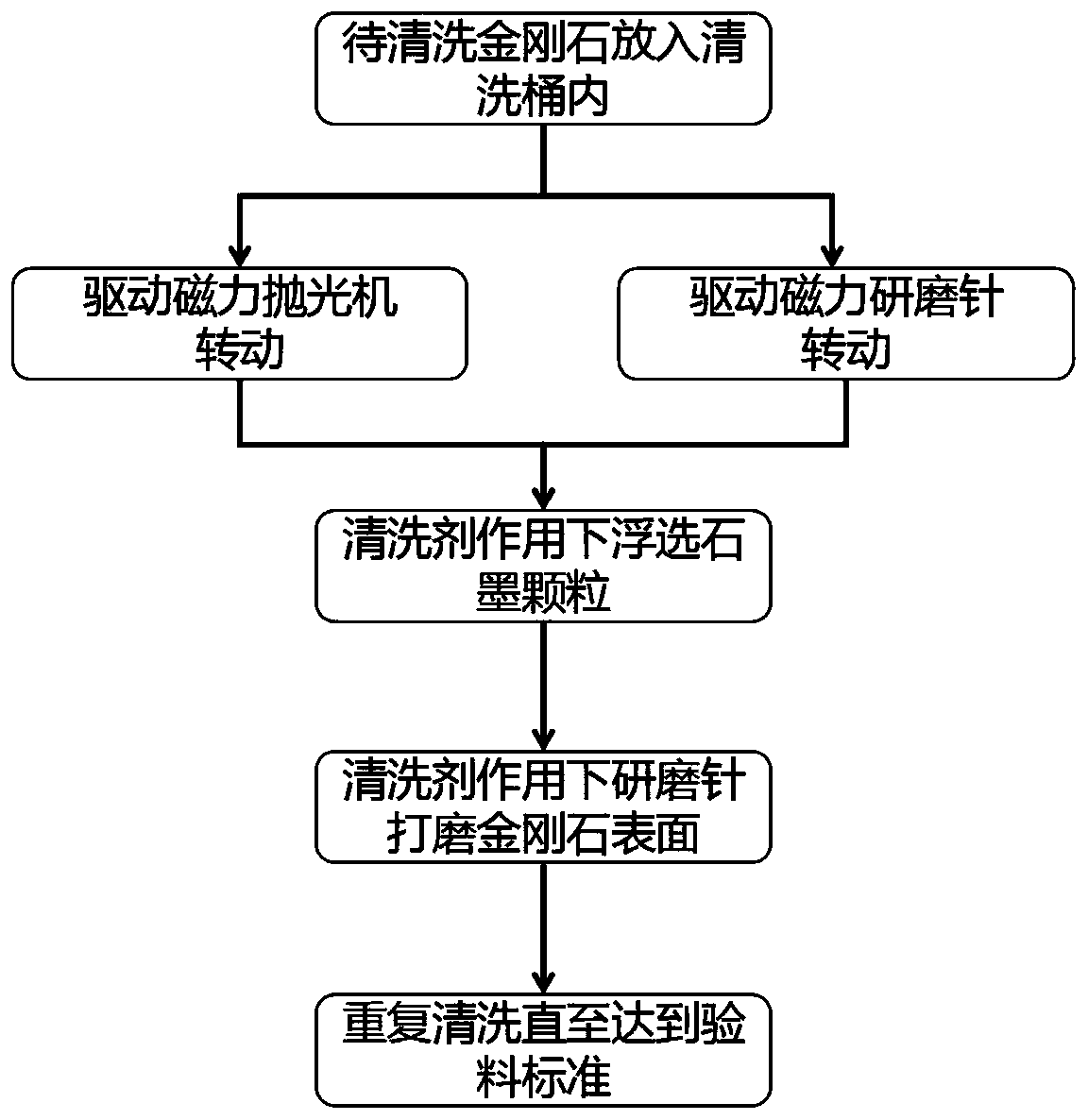

Method used

Image

Examples

Embodiment 1

[0026] Take 20 parts of water and 1 part of ethanol, after mixing, add 50 ppm of sodium lauryl sulfate, and add appropriate amount of hydrochloric acid to adjust the pH to about 3.0.

[0027] After the cleaning solution is prepared, put it into the cylinder of the magnetic polishing machine together with the magnetic grinding needle, and add 4 parts of diamond raw materials after electrolysis, shaking table, and magnetic separation processes.

[0028] Drive the disk of the polishing machine to rotate, after cleaning for 30 minutes, turn off the magnetic polishing machine, separate the fine graphite particles flotation from the foam by overflow, and turn on and off repeatedly until the graphite particles are completely flotation.

[0029] Then carry out the second cleaning, choose 20 parts of water and 0.8 parts of Fenton's reagent as the cleaning solution for the second cleaning, add an appropriate amount of hydrochloric acid to adjust the pH to 3.0, turn on the magnetic polish...

Embodiment 2

[0032] Take 30 parts of water and 2 parts of ethanol, after mixing, add 100ppm of sodium lauryl sulfate, and add appropriate amount of hydrochloric acid to adjust the pH to about 3.0.

[0033] After the cleaning solution is prepared, put it into the cylinder of the magnetic polishing machine together with the magnetic grinding needle, and add 4 parts of diamond raw materials after electrolysis, shaking table, and magnetic separation processes. Drive the disk of the polishing machine to rotate, after cleaning for 30 minutes, turn off the magnetic polishing machine, separate the fine graphite particles flotation from the foam by overflow, and turn on and off repeatedly until the graphite particles are completely flotation.

[0034] Then carry out the second cleaning, choose 30 parts of water and 1.2 parts of Fenton's reagent as the cleaning solution for the second cleaning, add an appropriate amount of hydrochloric acid to adjust the pH to 3.0, turn on the magnetic polishing mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com