Inorganic mixture high-speed stirring mechanism and application method thereof

A technology of high-speed mixing and application method, applied in cement mixing devices, chemical instruments and methods, and raw material supply devices for sales, etc. problems, to achieve the effect of shortening length, proportion and time, small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

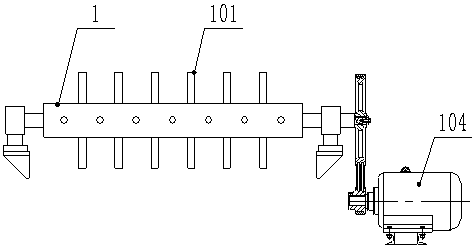

[0041] refer to figure 1 , the first embodiment of the present invention relates to a high-speed mixing mechanism for inorganic mixtures, including a material channel for breaking materials that can be arranged on the material passage between the material outlet 301 of the material conveyor 3 and the material inlet of the mixing tank 2. A high-speed stirring shaft 1 with graded stratification. Several stirring bodies 101 for turning and stirring materials are installed on the shaft wall of the high-speed stirring shaft 1. The stirring bodies 101 are in the shape of rods, blades, or picks. , any combination of two or three;

[0042] The rotating speed of the high-speed stirring shaft 1 is greater than the speed of the free-falling material output from the material conveyor 3 ; the input end of the high-speed stirring shaft 1 is connected to the driving device 104 .

[0043] The working process of the high-speed mixing mechanism for inorganic mixture is as follows:

[0044] li...

no. 2 approach

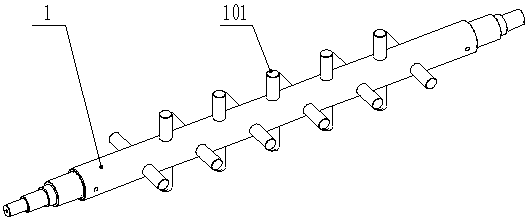

[0056] The difference between this embodiment and the first embodiment is that, referring to figure 2 , the stirring body 101 is rod-shaped, and the rod-shaped stirring body 101 vertically runs through the high-speed stirring shaft 1 and is symmetrically distributed on both sides of the high-speed stirring shaft 1. The adjacent stirring bodies 101 form an included angle with each other, and all the stirring bodies 101 are evenly spaced arranged.

[0057] The rod-shaped stirring body 101 is mainly suitable for small and medium-sized equipment and finely crushed materials, such as gravel. The arrangement of the rod-shaped stirring body 101 on the shaft wall of the high-speed stirring shaft 1 is not limited to figure 2 As shown, other arrangements are also possible, such as forming an angle other than a right angle to each other.

no. 3 approach

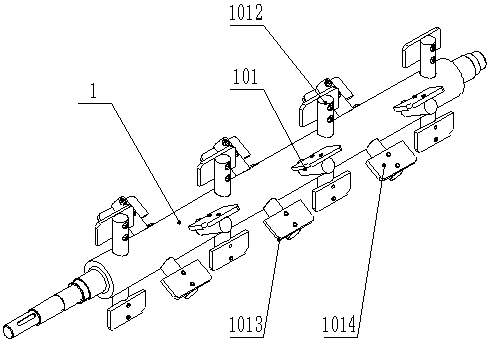

[0059] The difference between this embodiment and the first embodiment is that, referring to image 3 , the stirring body 101 is blade-shaped, and several blade-shaped stirring bodies 101 are uniformly distributed on the shaft wall of the high-speed stirring shaft 1, and two adjacent blade-shaped stirring bodies 101 are staggered to form an included angle, and each blade-shaped The stirring body 101 includes a supporting column 1012 vertically penetrating the high-speed stirring shaft 1. The part of the supporting column 1012 extending out of the high-speed stirring shaft 1 has the same length. 1013, the guide vane 1013 has two parallel and opposite planes, one of which is fixed to the column wall of the support column 1012, and the other plane is away from the column wall of the support column 1012, this plane is the stirring surface 1014, the same support column 1012 The stirring surfaces 1014 of the guide vanes 1013 at both ends are away from each other.

[0060] When mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com