Inorganic mixture high-speed stirring device and stirring method

A high-speed mixing and mixing technology, which is applied to cement mixing devices, chemical instruments and methods, and sales of raw material supply devices, etc., can solve the problems of inability to connect mixing tanks in series, high power consumption, etc., and achieve small footprint, easy implementation, The effect of low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

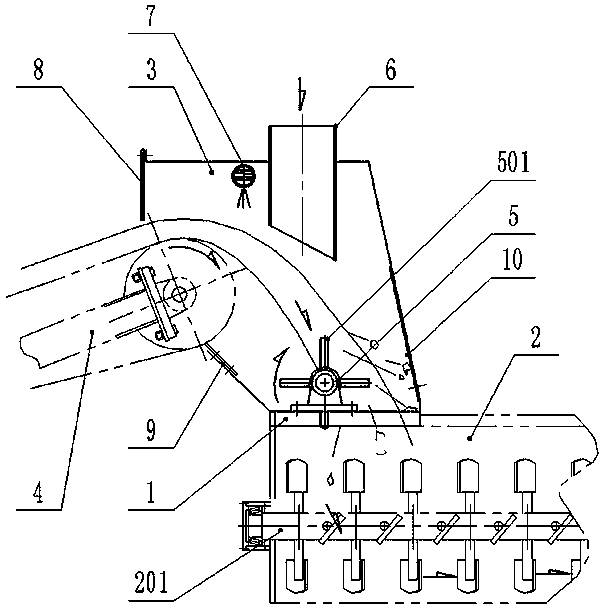

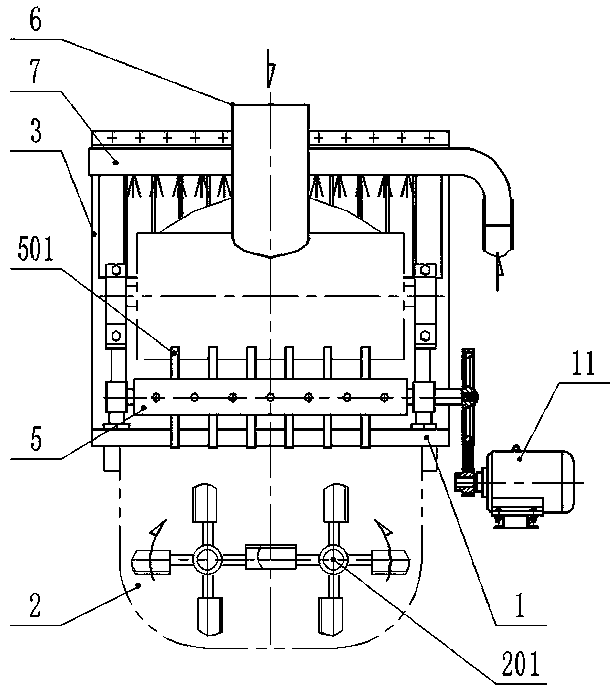

[0034] refer to figure 1 and figure 2 , the first embodiment of the present invention relates to a high-speed mixing device for inorganic mixtures, including a frame 1, a mixing tank 2 below the frame 1, a machine cover 3 above the frame 1, and the side wall of the machine cover 3 is sealed Connect the material conveyor 4, the discharge end of the material conveyor 4 extends into the hood 3, and also includes a high-speed stirring shaft 5 located in the hood 3, the high-speed stirring shaft 5 is located directly below the discharge end of the material conveyor 4 and Between the mixing tanks 2, the material output from the discharge end of the material conveyor 4 first passes through the high-speed mixing shaft 5 and then falls into the mixing tank 2. The input and output ends of the high-speed mixing shaft 5 are respectively fixed to the frame 1 through bearing seats. , the input end extends out of the machine cover 3 and is externally connected to the driving device 11; the...

no. 2 approach

[0046] This embodiment relates to a high-speed stirring device for inorganic mixture, such as figure 1 and figure 2 As shown, including the frame 1, the bottom of the frame 1 is the mixing tank 2, the top of the frame 1 is the hood 3, the side wall of the hood 3 is sealed and connected to the material conveyor 4, and the discharge end of the material conveyor 4 extends Into the machine cover 3, it also includes a high-speed stirring shaft 5 arranged in the machine cover 3. The high-speed stirring shaft 5 is located between the mixing cylinder 2 directly below the discharge end of the material conveyor 4, and is output from the discharge end of the material conveyor 4. The material first passes through the high-speed stirring shaft 5 and then falls into the mixing tank 2. The input end and output end of the high-speed stirring shaft 5 are fixedly connected to the frame 1 through the bearing seat respectively, and the input end extends out of the machine cover 3 and is external...

no. 3 approach

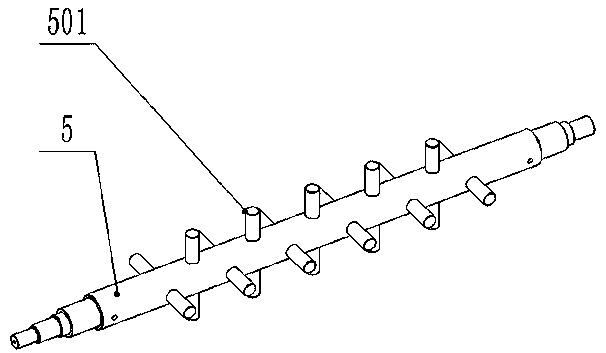

[0050] On the basis of the second embodiment, refer to image 3 , the stirring body 501 is rod-shaped, and the rod-shaped stirring body 501 vertically runs through the high-speed stirring shaft 5 and is symmetrically distributed on both sides of the high-speed stirring shaft 5. The adjacent stirring bodies 501 form an included angle (such as being perpendicular to each other, forming 60° each other) etc.), and all the stirring bodies 501 are evenly spaced.

[0051] The rod-shaped stirring body 501 is mainly suitable for small and medium-sized equipment and finely crushed materials, such as gravel. The arrangement of the rod-shaped stirring body 501 on the shaft wall of the high-speed stirring shaft 5 is not limited to image 3 As shown, other arrangements are also possible, such as forming an angle other than a right angle to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com