Electronic anti-swing method for intelligent crane

A crane and electronic technology, applied in the field of electronic anti-sway of intelligent cranes, can solve problems such as affecting system operation efficiency, and achieve the effects of optimizing running time, simple structure and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

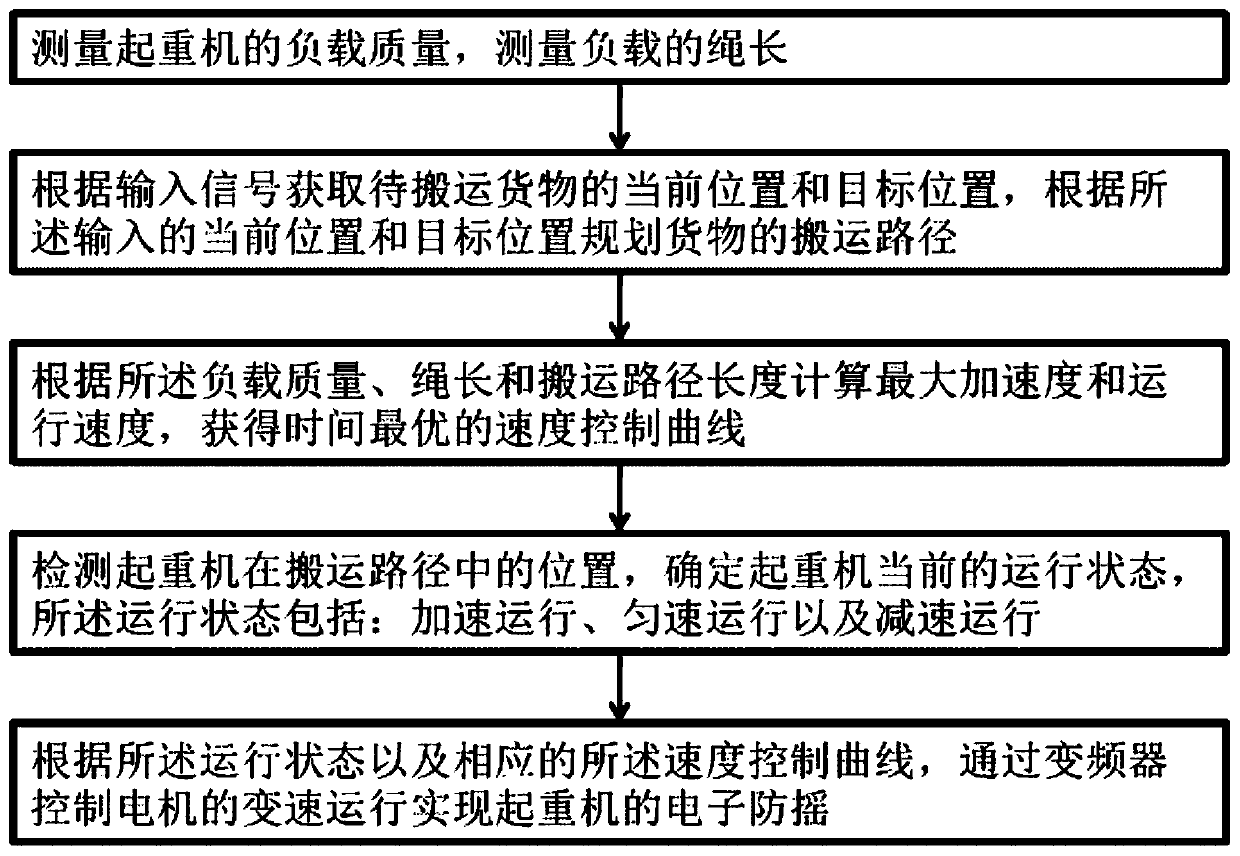

[0020] The invention provides an electronic anti-sway method for an intelligent crane. The specific implementation and working principle of the electronic anti-sway method for the crane of the present invention will be described below.

[0021] Cranes usually include carts, trolleys, lifting mechanisms and guide rails. Through the calculation and analysis of the operating characteristics of the crane and the single-degree-of-freedom dynamics of the large and small trolleys and hoisting weights, it is known that when the trolleys and trolleys are moving at constant acceleration, the swinging law of the hoisting weight is similar to that of a single pendulum in a non-inertial system If the law of motion is the same, when the large and small carts switch between constant acceleration motion and uniform speed motion, the swing speed value at the end of the previous state remains unchanged, and the swing angle is converted to the swing angle at the new swing equilibrium position an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com