Assembly type shrinkage-free sleeve grouting material and preparation method thereof

A sleeve grouting, non-shrinking technology, applied in the field of building materials, can solve the problems of large drop, poor fluidity, poor strength, etc., and achieve the effect of dense surface, good fluidity and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

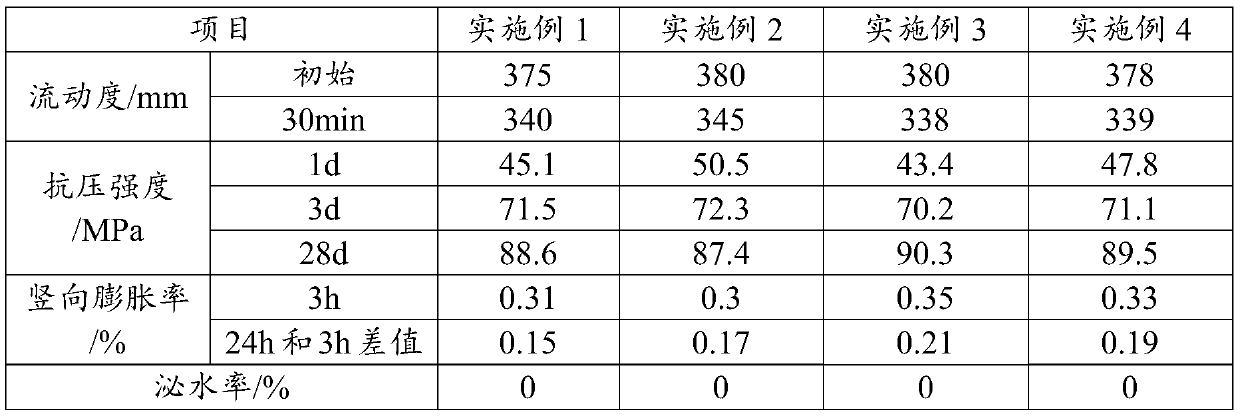

Examples

Embodiment 1

[0030] This embodiment provides a non-shrinkable sleeve grout for assembly, which is obtained through the following steps:

[0031] Add 49 parts of cement, 1 part of activated silica powder, 3.5 parts of expansion agent, 1 part of organic bentonite, 1 part of resin rubber powder, 0.3 part of water reducer, 0.1 part of defoamer and 0.1 part of retarder into the mixer and stir for 5 minutes. Then add 34 parts of 20-40 mesh quartz powder and stir for 5 minutes, then add 10 parts of 40-60 mesh quartz powder and stir for 5 minutes to obtain the above non-shrinkable sleeve grout for assembly.

Embodiment 2

[0033] This embodiment provides a non-shrinkable sleeve grout for assembly, which is obtained through the following steps:

[0034] Add 46 parts of cement, 1.5 parts of activated silica powder, 3.4 parts of expansion agent, 1.5 parts of organic bentonite, 2 parts of resin rubber powder, 0.3 parts of water reducer, 0.15 parts of defoamer and 0.15 parts of retarder into the mixer and stir for 5 minutes. Then add 35 parts of 20-40 mesh quartz powder and stir for 5 minutes, then add 10 parts of 40-60 mesh quartz powder and stir for 5 minutes to obtain the above non-shrinkable sleeve grout for assembly.

Embodiment 3

[0036] This embodiment provides a non-shrinkable sleeve grout for assembly, which is obtained through the following steps:

[0037] Add 49 parts of cement, 2 parts of activated silica powder, 4 parts of expansion agent, 1 part of organic bentonite, 1 part of resin rubber powder, 0.4 part of water reducer, 0.1 part of defoamer, and 0.1 part of retarder into the mixer and stir for 10 minutes. Then add 30 parts of 20-40 mesh quartz powder and stir for 5 minutes, then add 12.4 parts of 40-60 mesh quartz powder and stir for 5 minutes to obtain the above non-shrinkable sleeve grout for assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com