A kind of polyurethane elastomer with high load-bearing and low internal heat generation and preparation method thereof

A polyurethane elastomer and high load-bearing technology, which is applied in the field of preparation of roller materials, can solve problems affecting the service life of rollers, and achieve the effects of reducing internal heat generation, improving heat resistance, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

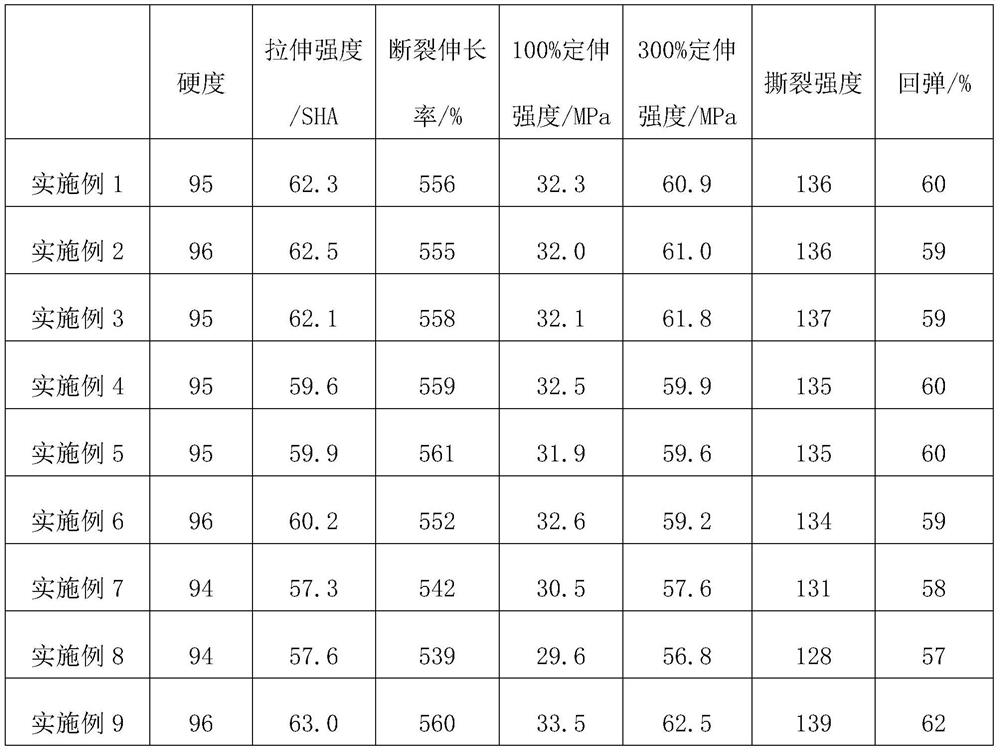

Examples

Embodiment 1

[0041] Example 1: A polyurethane elastomer with high load-bearing and low internal heat generation. The components and their corresponding parts by weight are shown in Table 1, and were prepared through the following steps:

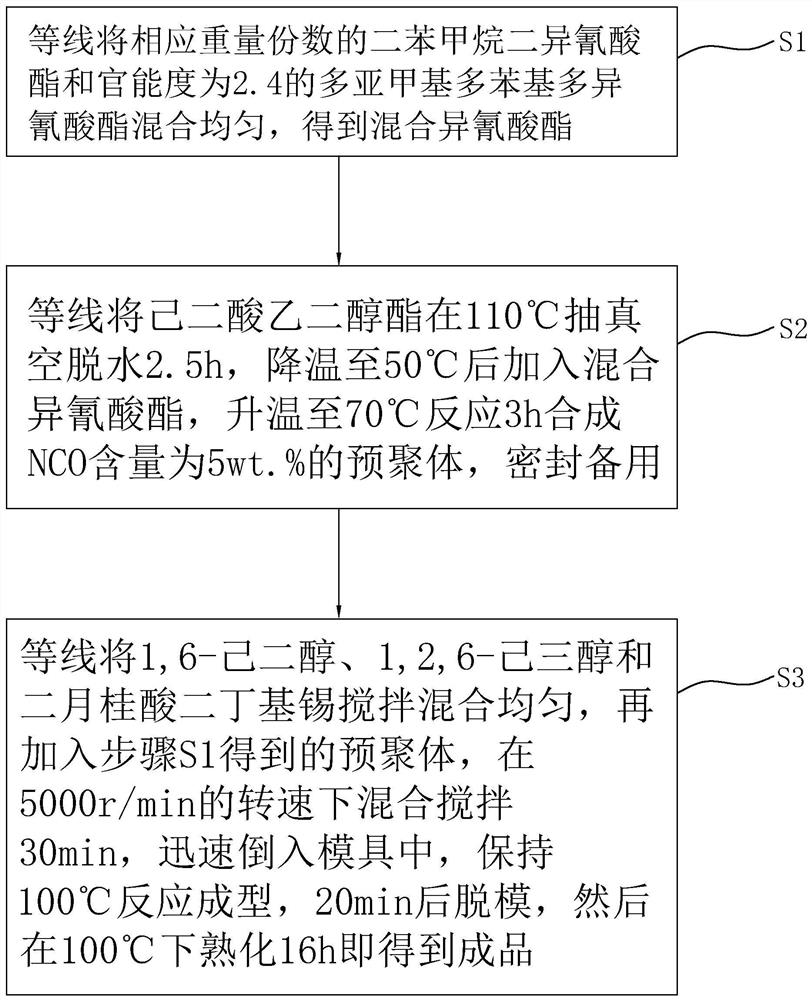

[0042] S1, uniformly mixing diphenylmethane diisocyanate and polymethylene polyphenyl polyisocyanate with a functionality of 2.4 in corresponding parts by weight to obtain a mixed isocyanate;

[0043] S2, dehydrating ethylene glycol adipate at 110° C. for 2.5 hours in a vacuum, cooling to 50° C., adding mixed isocyanate, heating to 70° C. and reacting for 3 hours to synthesize a prepolymer with an NCO content of 5 wt.%, and sealing it for later use;

[0044] S3, stir and mix 1,6-hexanediol, 1,2,6-hexanetriol, and dibutyltin dilaurate evenly, then add the prepolymer obtained in step S1, and mix and stir for 30min at a speed of 5000r / min , quickly poured into the mold, kept at 100°C for reaction molding, demolded after 20 minutes, and then aged at 100°C for...

Embodiment 2-6

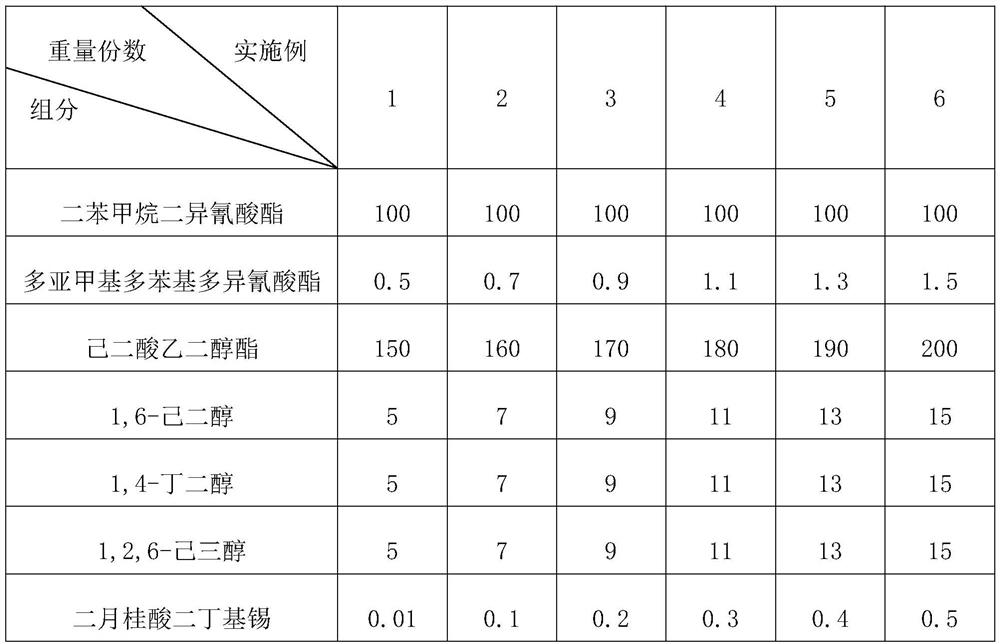

[0045] Example 2-6: A polyurethane elastomer with high load and low internal heat generation. The difference from Example 1 is that the components and their corresponding parts by weight are shown in Table 1.

[0046] Each component and parts by weight thereof in table 1 embodiment 1-6

[0047]

Embodiment 7

[0048] Example 7: A polyurethane elastomer with high load and low internal heat generation. The difference from Example 1 is that in step S3, 5 parts of polydimethylsiloxane and 5 parts of polytetrahydrofuran diol are added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com